.jpg)

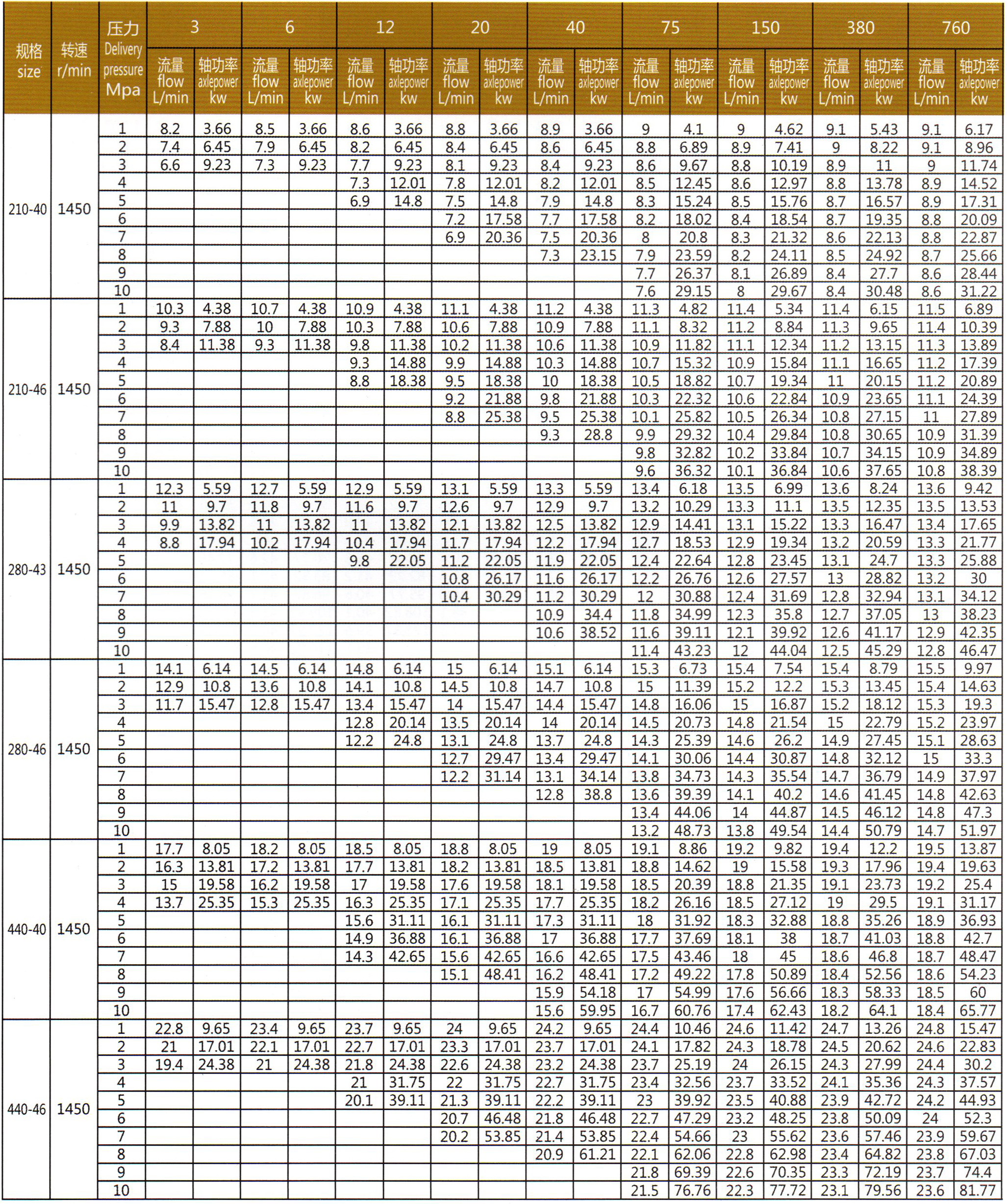

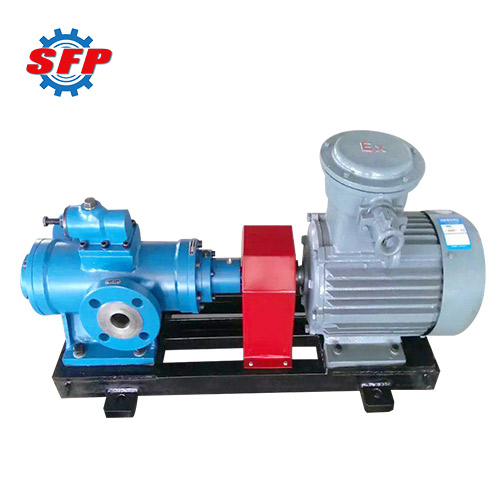

SM series fuel oil screw pumps are used for conveying medium with temperature ≤150℃, viscosity 3-760cSt, no solid particles, non-corrosive, and lubricating performance. It is worth mentioning that the overflow metal parts can be made of different materials to meet the requirements of different working media and working conditions. Therefore, it can be major cement building materials, rubber tires, internal mixers, coal power, diesel and heavy oil, as well as fuel transportation, water conservancy engineering, marine engineering, petrochemical and other industries.

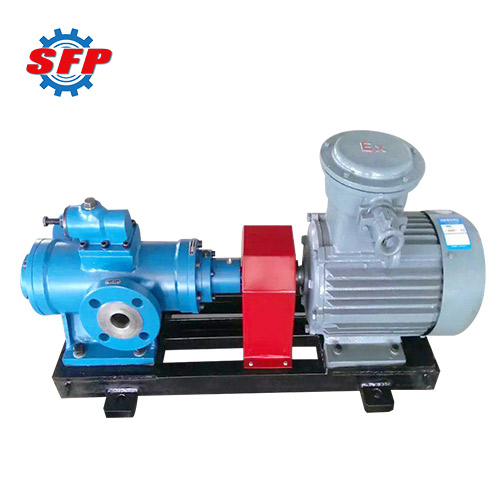

1. Power generation: Used for conveying pumps, oil supply pumps, and loading pumps to transport light diesel oil, heavy diesel oil, light diesel oil, heavy oil, crude oil, coolant, cooling water, grinding fluid, wax-based thin oil, and other media.

2. Petroleum and natural gas refineries: For conveying, circulating, mixing, or transporting various clean, lubricating, low/high-viscosity liquids such as engine oil, lubricating oil, crude oil, fuel oil, asphalt, grease, and paraffin.

4. Chemical industry: It is suitable for various clean, lubricating, low/high viscosity liquids, such as additives, resins, grease, adhesives, isocyanates, polyethers, and coatings.