.jpg)

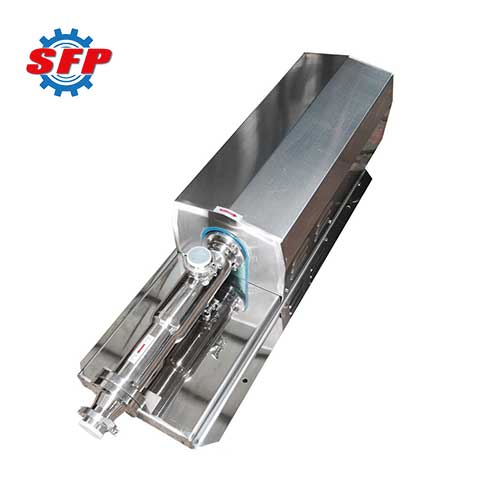

G series sludge screw pump is able to be used in the sewage treatment, chemical, energy, paper, ceramic, exploration and mining, pharmaceutical, food and cosmetic industries to handle high viscosity media containing solid particles. The output pressure of this pump is usually 0.6 MPa and the head can be up to 60 m, which can meet the requirements of the medium with a temperature of less than 80 ° C. Moreover, the output liquid of this product is continuous and uniform, with stable pressure and little stirring, and no change in composition will occur to the sensitive liquid.

G series electric screw pump's stator is made of a variety of elastic materials, so the pump can transport highly viscous fluids, as well as hard suspended particulate media or media containing fibers. The flow rate of the product is proportional to the rotational speed, and the transmission can be directly driven by couplings, or by speed-regulated motors, delta belts, gear box transmissions. The product has few parts, compact structure, small volume, simple maintenance, easy installation and disassembly.

(4).png)

(2).png)

| Model | Flow (m³/h) |

Pressure (MPa) |

Speed (r/min) |

Motor Power (kw) |

Inlet Size (mm) |

Outlet Size (mm) |

Max Solid Size (mm) |

Max Fiber Length (mm) |

| G10-1 | 0.1 | 0.6 | 960 | 0.55 | 25 | 25 | 0.8 | 15 |

| G10-2 | 1.2 | 0.55 | 25 | 25 | ||||

| G13-1 | 0.4 | 0.6 | 960 | 0.55 | 25 | 25 | 0.8 | 15 |

| G13-2 | 1.2 | 0.55 | 25 | 25 | ||||

| G15-1 | 0.6 | 0.6 | 960 | 0.55 | 25 | 25 | 1 | 20 |

| G15-2 | 1.2 | 0.75 | 25 | 25 | ||||

| G20-1 | 0.8 | 0.6 | 960 | 0.75 | 25 | 25 | 1.5 | 25 |

| G20-2 | 0.6 | 1.1 | 25 | 25 | ||||

| G25-1 | 2 | 0.6 | 960 | 1.5 | 32 | 25 | 2 | 30 |

| G25-2 | 1.2 | 2.2 | 32 | 25 | ||||

| G30-1 | 5 | 0.6 | 960 | 2.2 | 50 | 40 | 2.5 | 30 |

| G30-2 | 1.2 | 3 | 50 | 40 | ||||

| G35-1 | 8 | 0.6 | 960 | 3 | 65 | 50 | 3 | 40 |

| G35-2 | 1.2 | 4 | 65 | 50 | ||||

| G40-1 | 12 | 0.6 | 960 | 4 | 80 | 65 | 3.8 | 45 |

| G40-2 | 1.2 | 5.5 | 80 | 65 | ||||

| G50-1 | 20 | 0.6 | 960 | 5.5 | 100 | 80 | 5 | 50 |

| G50-2 | 1.2 | 7.5 | 100 | 80 | ||||

| G60-1 | 30 | 0.6 | 960 | 11 | 125 | 100 | 6 | 60 |

| G60-2 | 1.2 | 15 | 125 | 100 | ||||

| G70-1 | 45 | 0.6 | 720 | 11 | 150 | 125 | 8 | 70 |

| G70-2 | 1.2 | 18.5 | ||||||

| G85-1 | 65 | 0.6 | 720 | 15 | 150 | 150 | 10 | 80 |

| G85-2 | 0.6 | 30 | ||||||

| G105-1 | 80 | 0.6 | 720 | 22 | 200 | 150 | 10 | 80 |

| G135-1 | 100 | 0.6 | 720 | 30 | 200 | 150 | 10 | 80 |