.jpg)

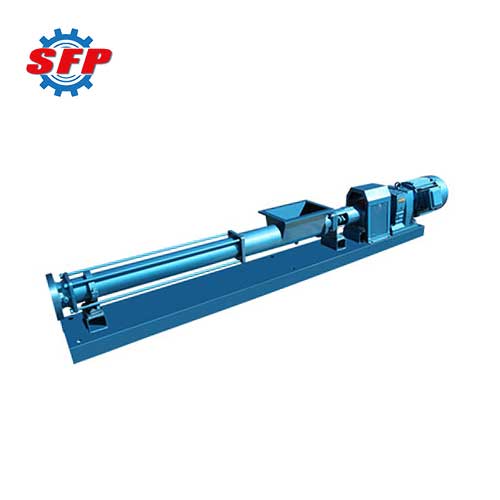

G series stainless steel screw pumps can be applied to transport various fluid media, but also can transport high viscosity media, media containing hard suspended particles or solid particles. Therefore, it is usually widely used in shipping, petroleum, food, construction, chemical, paper making, power plant and other industries. Moreover, the pump adopts reasonable design structure and advanced technology, the output liquid is continuous and even, the pressure is stable, the stirring is small, and there is no change in the composition of the sensitive liquid.

(4).png)

(4).png)

(2).png)

1. It is characterized by high self-priming capacity, it can complete self-priming without auxiliary device.

2. This pump has few parts, small volume and light weight, so it is easy to maintain, easy to install and dismantle.

3. It has a uniform flow rate, low pressure pulsation, and the flow rate is proportional to the rotational speed, which can be adjusted to realize variable conveying or metering.

4. The pump is low noise, no vortex and churning, little damage to the media composition, suitable for food, medicine, chemical, sewage treatment, construction and other industries.

| Model | Flow (m³/h) |

Pressure (Mpa) |

Speed (r/min) |

Power (kw) |

NPSH (m) |

Inlet (mm) |

Outlet (mm) |

Grain Diameter (mm) |

Fiber Length (mm) |

| G20-1 | 0.8 | 0.6 | 960 | 0.75 | 4 | 25 | 25 | 1.5 | 25 |

| G20-2 | 1.2 | 1.5 | |||||||

| G25-1 | 2 | 0.6 | 960 | 1.5 | 32 | 25 | 2 | 30 | |

| G25-2 | 1.2 | 2.2 | |||||||

| G30-1 | 5 | 0.6 | 960 | 2.2 | 50 | 40 | 2.5 | 35 | |

| G30-2 | 1.2 | 3 | |||||||

| G35-1 | 8 | 0.6 | 960 | 3 | 65 | 50 | 3 | 40 | |

| G35-2 | 1.2 | 4 | |||||||

| G40-1 | 12 | 0.6 | 960 | 4 | 80 | 65 | 3.8 | 45 | |

| G40-2 | 1.2 | 5.5 | |||||||

| G50-1 | 20 | 0.6 | 960 | 5.5 | 4.5 | 100 | 80 | 5 | 50 |

| G50-2 | 1.2 | 7.5 | |||||||

| G60-1 | 30 | 0.6 | 960 | 11 | 5 | 125 | 100 | 6 | 60 |

| G60-2 | 1.2 | 15 | |||||||

| G70-1 | 45 | 0.6 | 720 | 11 | 150 | 125 | 8 | 70 | |

| G70-2 | 1.2 | 15 | |||||||

| G85-1 | 60 | 0.6 | 720 | 15 | 150 | 150 | 10 | 80 | |

| G85-2 | 1.2 | 450 | 22 | ||||||

| G105-1 | 80 | 0.6 | 400 | 22 | 200 | 200 | 15 | 110 | |

| G105-2 | 1.2 | 350 | 30 | ||||||

| G135-1 | 120 | 0.6 | 350 | 37 | 250 | 250 | 20 | 150 | |

| G135-2 | 1.2 | 280 |