Summarize:

.jpg)

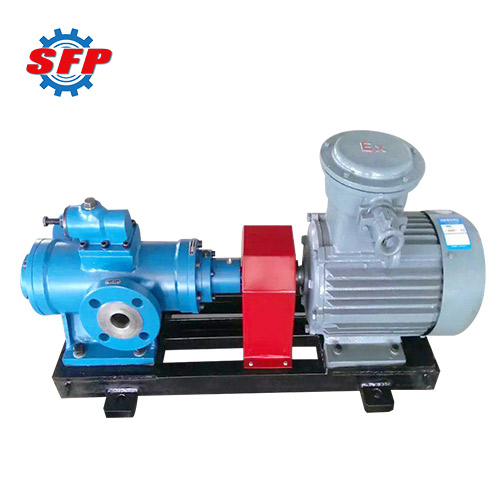

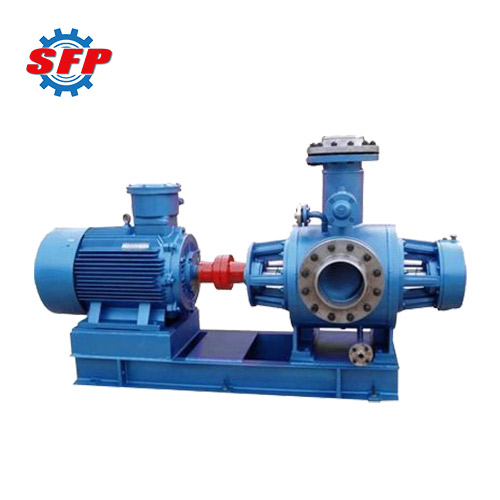

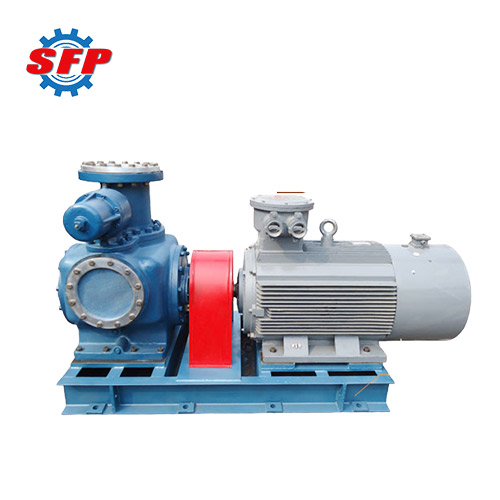

2W/W series twin screw pump can convey various viscosity, lubricating properties and media containing small amount of impurities, such as crude oil, fuel oil, water glycol, hydraulic oil, gear oil and so on. It is usually can be widely used in machinery, petroleum, metallurgy, chemical industry, shipping, food and other industries. And it is characterized by no pulsation, no agitation, low vibration, low noise and smoothness when conveying liquid.

Product Details:

The pump is formed by the mutual meshing of the master and slave screws in the pump body, as well as the cooperation between the screws and the holes in the pump body, forming a sealed cavity in the pump body. When the screw rotates, these sealing cavities continuously move forward, pushing the liquid in the sealing cavity to the outlet to realize the purpose of transporting liquid.

Application:

1. Oil and Gas: The unit is ideal for pumping crude oil, natural gas, water and solid mixtures, and can be used both onshore and offshore. Multiphase crude oil transportation, thermal power plants and crude oil storage can be realized with this equipment.

2. Petrochemical and Oil Refineries: This pump can transport low-viscosity liquids, including neutral, alkaline, acidic or gaseous or abrasive media. Including heavy oil, asphalt, tar, heavy duel and chemical products.

3. Chemical Industry: Regardless of low viscosity or high viscosity, it can transport all kinds of liquids with corrosive and solid particles. It is applicable for polymers, coatings, slurries, liquid sulfur and chemical.

4. Ocean: It can be used on tankers for loading and conveying, and for lubricating the main engine.

Feature:

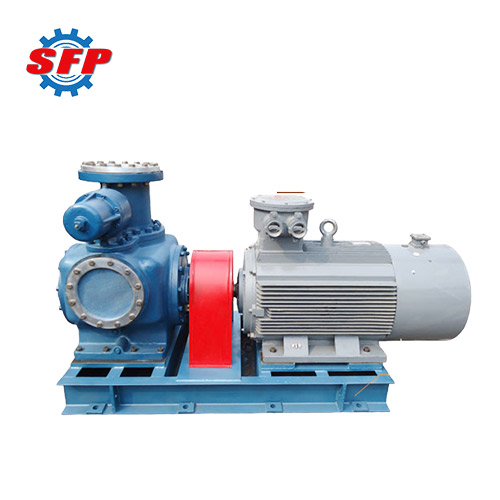

1. Its body with heating jacket, can transport a variety of clean or contain small solid particles (general particle diameter of less than 0.12-0.2mm) of low-viscosity or high-viscosity media.

2. Strong self-absorption performance, multi-phase mixed conveying with gas content not higher than 80%, sand content not higher than 500g/m3.

3. Adopting mechanical seal or bellows mechanical seal, it has the characteristics of long life, less leakage, and wide range of application.

4. Utilizing synchronous gear drive, no contact between the two rotors, even if a short time idling can also ensure the delivery.

5. Twin-screw pump with external bearing structure and independent lubrication can transport various non-lubricating media.

6. The correct choice of materials, and can even transport many corrosive media.

.jpg)