Summarize:

.jpg)

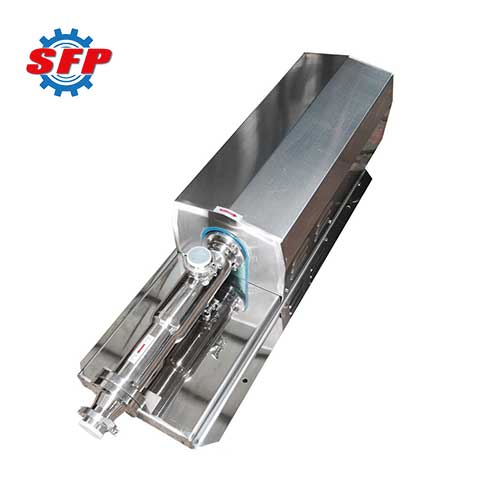

G series horizontal screw pump is a new-generation transfer pump designed based on the rotary positive displacement principle, suitable for conveying high-viscosity media containing solid particles in industries such as chemical, energy, papermaking, pharmaceutical, food processing, and wastewater treatment. This equipment delivers stable flow rates and constant pressure without pulsation during transfer, preventing changes in sensitive liquid components and thus preserving the original properties and structure of the conveyed medium.

Product Details:

G screw oil pump utilizes a rotary positive displacement principle, primarily consisting of a rotor and an elastic stator that continuously mesh to form sealed cavities, which allows the medium to be uniformly propelled axially, achieving the pumping objective. This method of conveyance results in low internal flow velocity, constant volume, and stable pressure, thus better preventing damage to the structure of the medium being transported.

.png)

Application:

1. Environmental Protection: iIt is particularly suitable for treating industrial wastewater, domestic sewage, and sludge containing solid particles and short fibers, such as in oil-water separators and plate and frame filter press equipment.

2. Petroleum Industry: Transporting crude oil, mixtures of crude oil and water, mixtures of natural gas and water, and injecting polymers into geological formations.

3. Shipbuilding Industry: Circulating and transporting materials such as bilge water, oil and water mixtures, oil residue, and oily wastewater during ship cleaning.

4. Printing Industry: High-viscosity inks, wallpaper PVC polymer pastes, and paper pulp and short-fiber slurries of various concentrations.

5. Food Industry: Various viscous starches, distiller's grains, grain residues, various sauces, fruit pulp, and solid slurries.

Feature:

1. This pump provides a uniform flow rate with minimal pressure pulsation during operation, making it suitable for applications requiring high flow stability.

2. It can maintain a stable output pressure within a certain pressure range, making it suitable for applications requiring precise pressure control.

3. This series of pumps has excellent self-priming capabilities, allowing it to self-prime and transfer media in a short time.

4. It has a small number of parts, reducing potential failure points and improving reliability.

Performance Data:

| Model |

Flow

(m³/h) |

Pressure

(MPa) |

Speed

(r/min) |

Motor Power

(kw) |

Inlet Size

(mm) |

Outlet Size

(mm) |

Max Solid Size

(mm) |

Max Fiber Length

(mm) |

| G10-1 |

0.1 |

0.6 |

960 |

0.55 |

25 |

25 |

0.8 |

15 |

| G10-2 |

1.2 |

0.55 |

25 |

25 |

| G13-1 |

0.4 |

0.6 |

960 |

0.55 |

25 |

25 |

0.8 |

15 |

| G13-2 |

1.2 |

0.55 |

25 |

25 |

| G15-1 |

0.6 |

0.6 |

960 |

0.55 |

25 |

25 |

1 |

20 |

| G15-2 |

1.2 |

0.75 |

25 |

25 |

| G20-1 |

0.8 |

0.6 |

960 |

0.75 |

25 |

25 |

1.5 |

25 |

| G20-2 |

0.6 |

1.1 |

25 |

25 |

| G25-1 |

2 |

0.6 |

960 |

1.5 |

32 |

25 |

2 |

30 |

| G25-2 |

1.2 |

2.2 |

32 |

25 |

| G30-1 |

5 |

0.6 |

960 |

2.2 |

50 |

40 |

2.5 |

30 |

| G30-2 |

1.2 |

3 |

50 |

40 |

| G35-1 |

8 |

0.6 |

960 |

3 |

65 |

50 |

3 |

40 |

| G35-2 |

1.2 |

4 |

65 |

50 |

| G40-1 |

12 |

0.6 |

960 |

4 |

80 |

65 |

3.8 |

45 |

| G40-2 |

1.2 |

5.5 |

80 |

65 |

| G50-1 |

20 |

0.6 |

960 |

5.5 |

100 |

80 |

5 |

50 |

| G50-2 |

1.2 |

7.5 |

100 |

80 |

| G60-1 |

30 |

0.6 |

960 |

11 |

125 |

100 |

6 |

60 |

| G60-2 |

1.2 |

15 |

125 |

100 |

| G70-1 |

45 |

0.6 |

720 |

11 |

150 |

125 |

8 |

70 |

| G70-2 |

1.2 |

18.5 |

| G85-1 |

65 |

0.6 |

720 |

15 |

150 |

150 |

10 |

80 |

| G85-2 |

0.6 |

30 |

| G105-1 |

80 |

0.6 |

720 |

22 |

200 |

150 |

10 |

80 |

| G135-1 |

100 |

0.6 |

720 |

30 |

200 |

150 |

10 |

80 |

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.jpg)