.png)

.jpg)

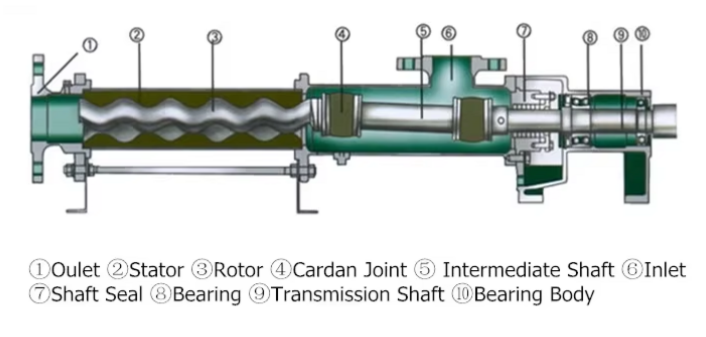

G series screw oil pump is a rotary displacement pump, which can transport high viscosity, media containing hard suspended particles or solid particles and various flowable media. It is suitable for construction, power plant, energy, printing, ceramics, mining and other industries. What's more, the liquid output using this pump is continuous and uniform, with stable pressure and small stirring, and there will be no change in the composition of the sensitive liquid. Hence it has also become the preferred equipment for food, brewing, pharmaceutical, chemical and other industries.

.png)

| Model | Flow (m³/h) |

Pressure (Mpa) |

Speed (r/min) |

Power (kw) |

NPSH (m) |

Inlet (mm) |

Outlet (mm) |

Grain Diameter (mm) |

Fiber Length (mm) |

| G20-1 | 0.8 | 0.6 | 960 | 0.75 | 4 | 25 | 25 | 1.5 | 25 |

| G20-2 | 1.2 | 1.5 | |||||||

| G25-1 | 2 | 0.6 | 960 | 1.5 | 32 | 25 | 2 | 30 | |

| G25-2 | 1.2 | 2.2 | |||||||

| G30-1 | 5 | 0.6 | 960 | 2.2 | 50 | 40 | 2.5 | 35 | |

| G30-2 | 1.2 | 3 | |||||||

| G35-1 | 8 | 0.6 | 960 | 3 | 65 | 50 | 3 | 40 | |

| G35-2 | 1.2 | 4 | |||||||

| G40-1 | 12 | 0.6 | 960 | 4 | 80 | 65 | 3.8 | 45 | |

| G40-2 | 1.2 | 5.5 | |||||||

| G50-1 | 20 | 0.6 | 960 | 5.5 | 4.5 | 100 | 80 | 5 | 50 |

| G50-2 | 1.2 | 7.5 | |||||||

| G60-1 | 30 | 0.6 | 960 | 11 | 5 | 125 | 100 | 6 | 60 |

| G60-2 | 1.2 | 15 | |||||||

| G70-1 | 45 | 0.6 | 720 | 11 | 150 | 125 | 8 | 70 | |

| G70-2 | 1.2 | 15 | |||||||

| G85-1 | 60 | 0.6 | 720 | 15 | 150 | 150 | 10 | 80 | |

| G85-2 | 1.2 | 450 | 22 | ||||||

| G105-1 | 80 | 0.6 | 400 | 22 | 200 | 200 | 15 | 110 | |

| G105-2 | 1.2 | 350 | 30 | ||||||

| G135-1 | 120 | 0.6 | 350 | 37 | 250 | 250 | 20 | 150 |

.jpg)