Summarize:

.jpg)

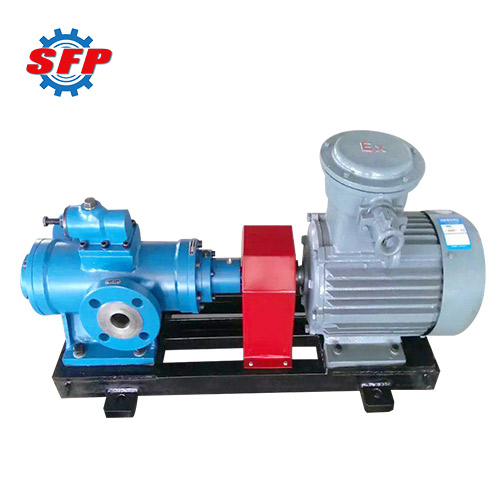

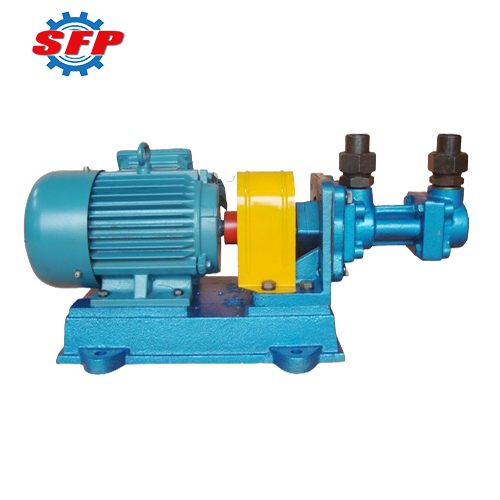

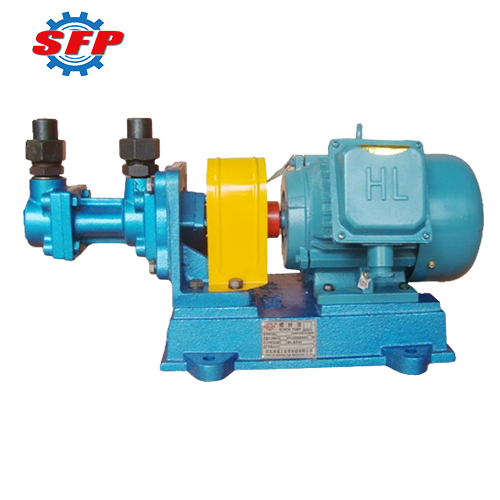

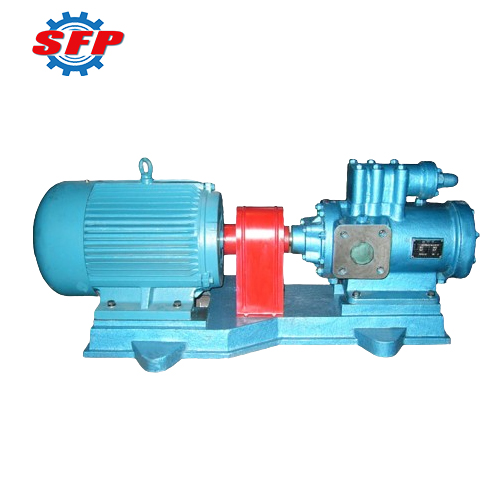

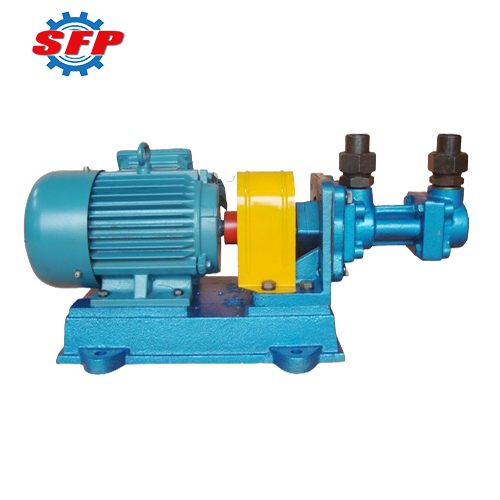

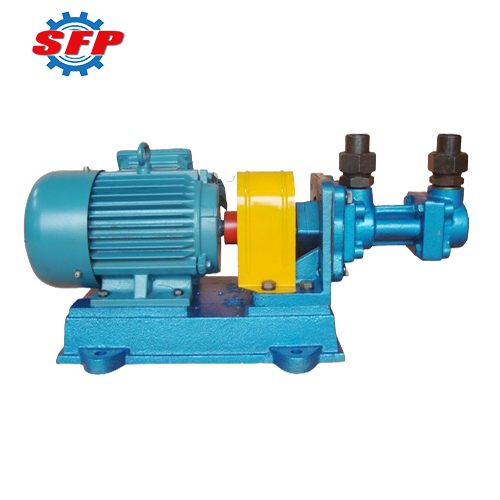

3G series three screw pump with high volumetric and mechanical efficiencies, designed for conveying non-solid particles, non-corrosive oils and lubricating liquids similar to oil. Therefore, they are usually used by users in petroleum, chemical, metallurgy, electric power, shipbuilding, machinery manufacturing and other industries. Moreover, the pump has the advantages of high efficiency and energy saving, smooth operation, simple structure and reasonable design.

Product Details:

3G series triple screw pump is a rotor type volumetric pump, which utilizes the screw meshing principle, relying on the rotating screws meshing with each other in the pump casing to enclose the conveying medium in the gear cavity and push it continuously and uniformly to the outlet along the axial direction of the screws, thus providing a stable pressure for the system. It is made of cast steel with insulated and non-insulated materials. When high viscosity medium needs to be handled, it is recommended to use screw pump with insulated structure.

Application:

3G series asphalt screw pump is suitable for conveying all kinds of non-corrosive oils and similar oils, such as fuel oil, lubricating oil, hydraulic oil, heavy oil, asphalt and other similar oils. The viscosity of the conveyed liquid is generally 30-760mm/s. High-viscosity media can be conveyed by means of heating to reduce the viscosity, and the temperature generally does not exceed 350℃. It is widely used in petroleum, chemical fiber, metallurgy, machinery, electric power, machine tool, ship, glass, highway and other industries.

(3).png)

Feature:

1. The liquid is transported continuously in the direction of thrust without agitation and the sealed chamber operates as an infinite piston, so that a high suction range can be easily ensured without cavitation.

2. When the pump is used to transfer liquids, the liquid is enclosed in a chamber sealed by the rotors and sleeves, and the process from suction to discharge proceeds continuously without pulsation or agitation.

3. The rotating elements of the pump are only three rotors and rotate by liquid pressure, thus ensuring natural, smooth and quiet operation even at high speeds and high pressures.

4. Its internal leakage losses are also low through precision machining of the rotating elements.

5. It can be directly connected to motors and turbines without reduction.

Performance Data:

| Model |

Flow |

Pressure

Mpa |

Speed

r/min |

Power KW |

| m³/h |

L/min |

Shaft |

Motor |

| 90*2-42 |

28.2 |

470.9 |

0.6 |

950 |

6.6 |

11 |

| 27.5 |

457.6 |

1.0 |

10.2 |

15 |

| 43.1 |

718.8 |

0.6 |

1450 |

10 |

15 |

| 41.9 |

698.5 |

1.0 |

15.5 |

18.5 |

| 90*2-46 |

34.0 |

566.7 |

0.8 |

950 |

9.7 |

11 |

| 52.6 |

875.4 |

0.6 |

1450 |

12 |

15 |

| 520 |

866 |

0.8 |

14.9 |

18.5 |

| 51.4 |

8561 |

1.0 |

18.6 |

22 |

| 100*2-46 |

48.0 |

800 |

0.8 |

950 |

13.3 |

15 |

| 72.7 |

1212 |

0.6 |

1450 |

165 |

18.5 |

| 72.0 |

1200 |

0.8 |

20.4 |

22 |

| 71.2 |

1187 |

1.0 |

25.5 |

30 |

| 100*2-51 |

56.9 |

948.9 |

0.6 |

950 |

12.5 |

15 |

| 55.7 |

928.6 |

1.0 |

20.8 |

30 |

| 86.9 |

1448.3 |

0.6 |

1450 |

19.1 |

22 |

| 850 |

1417.2 |

1.0 |

31.8 |

37 |

| 110*2-46 |

60.9 |

1015 |

0.6 |

950 |

13.7 |

18.5 |

| 58.9 |

951.7 |

1.0 |

21.8 |

30 |

| 96.7 |

1611 |

0.6 |

1450 |

21.9 |

30 |

| 94.6 |

1577 |

1.0 |

33.9 |

45 |

| 120*2-42 |

67.9 |

1131 |

0.6 |

950 |

15.5 |

18.5 |

| 65.4 |

1090 |

1.0 |

24.5 |

30 |

| 108 |

1802 |

0.6 |

1450 |

24.7 |

30 |

| 105 |

1760 |

1.0 |

38.2 |

45 |

| 120*2-46 |

79.6 |

1327 |

0.6 |

950 |

17.8 |

22 |

| 77.2 |

1285 |

1.0 |

28.2 |

37 |

| 126 |

2101 |

0.6 |

1450 |

28.5 |

37 |

| 123 |

2059 |

1.0 |

44.1 |

55 |

| 150*2-46 |

158 |

2640 |

0.6 |

950 |

34.6 |

45 |

| 154 |

2582 |

1.0 |

54.5 |

75 |

| 241.7 |

4029.7 |

0.6 |

1450 |

53.8 |

7590 |

| 236.5 |

3942.2 |

1.0 |

82.2 |

.jpg)

(3).png)