Summarize:

.jpg)

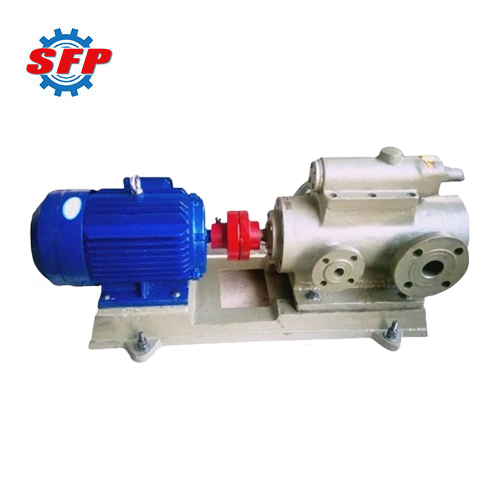

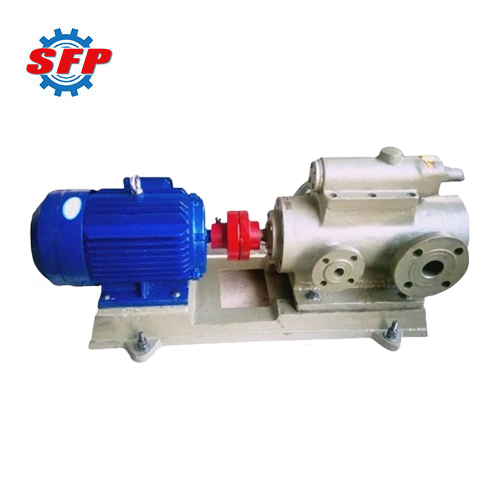

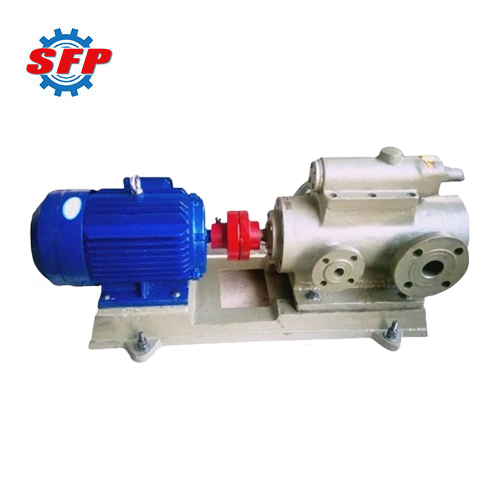

3GB series three screw pumps are suitable for conveying oil and oil-like lubricating liquids that do not contain solid particles and are non-corrosive, including heavy oil, crude oil, diesel oil, pressurized fluid oil and so on. With its advantages of corrosion resistance, heat resistance, good self-priming performance, cobbled together structural parts, easy maintenance, etc., it is widely used in the fields of chemical fiber, petroleum, machinery, ship, glass, highway, metallurgy and so on.

Product Details:

3GB series fuel oil screw pump is a rotor-type volumetric pump, which uses the principle of screw meshing and relies on the rotating screws meshing with each other in the pump casing to enclose the conveying medium in the gear cavity and push it continuously and uniformly along the axial direction of the screws to the outlet, so as to provide stable pressure for the system. It is manufactured from cast steel and is available in both insulated and non-insulated materials. When handling high viscosity media, it is recommended to use screw pumps with insulated construction.

Application:

3GB series screw oil pump is suitable for conveying various non-corrosive oils and similar oils, such as fuel oil, lubricating oil, hydraulic oil, heavy oil, asphalt and other similar oils. The viscosity of the conveyed liquid is generally 30-760mm/s. High-viscosity media can be conveyed by heating to reduce viscosity, and the temperature is generally not more than 350 °C. The equipment is widely used in petroleum, chemical fiber, metallurgy, machinery and other industries. Widely used in petroleum, chemical fiber, metallurgy, machinery, electric power, machine tools, ships, glass, highway and other industries.

(2).png)

Advantage:

1. Good sealing performance: The use of mechanical seals, according to different media, the mechanical seal friction parts of different materials, for high viscosity media, the choice of high mechanical strength, good wear resistance of cemented carbide materials, to ensure the sealing performance at high temperatures.

2. Low noise: The rotating part of the screw pump has small inertia, and the starting torque and vibration are very small, which makes the pump have low noise during operation.

3. Small pressure pulsation: Due to the meshing effect of the screw, the pressure pulsation in the pump body is small, so as to ensure the stability of the conveyed liquid.

4. Stable flow: The continuous rotation of the screw enables the liquid to be pushed to the outlet smoothly, ensuring the stability of the flow.

5. Simple structure: Its overall structure is relatively simple, but ensures efficient and stable operation.

Performance Data:

| Model |

Flow |

Pressure

(Mpa) |

Speed

(r/min) |

Power KW |

NPSHr

(m) |

| m³/h |

L/min |

Shaft |

Motor |

| 90*2-42 |

28.2 |

470.9 |

0.6 |

950 |

6.6 |

11 |

5.5 |

| 27.5 |

457.6 |

1.0 |

10.2 |

15 |

| 43.1 |

718.8 |

0.6 |

1450 |

10 |

15 |

| 41.9 |

698.5 |

1.0 |

15.5 |

18.5 |

| 90*2-46 |

34.0 |

566.7 |

0.8 |

950 |

9.7 |

11 |

5.5 |

| 52.6 |

875.4 |

0.6 |

1450 |

12 |

15 |

| 520 |

866 |

0.8 |

14.9 |

18.5 |

| 51.4 |

8561 |

1.0 |

18.6 |

22 |

| 100*2-46 |

48.0 |

800 |

0.8 |

950 |

13.3 |

15 |

5.5 |

| 72.7 |

1212 |

0.6 |

1450 |

165 |

18.5 |

| 72.0 |

1200 |

0.8 |

20.4 |

22 |

| 71.2 |

1187 |

1.0 |

25.5 |

30 |

| 100*2-51 |

56.9 |

948.9 |

0.6 |

950 |

12.5 |

15 |

5.5 |

| 55.7 |

928.6 |

1.0 |

20.8 |

30 |

| 86.9 |

1448.3 |

0.6 |

1450 |

19.1 |

22 |

| 850 |

1417.2 |

1.0 |

31.8 |

37 |

| 110*2-46 |

60.9 |

1015 |

0.6 |

950 |

13.7 |

18.5 |

5.5 |

| 58.9 |

951.7 |

1.0 |

21.8 |

30 |

| 96.7 |

1611 |

0.6 |

1450 |

21.9 |

30 |

| 94.6 |

1577 |

1.0 |

33.9 |

45 |

| 120*2-42 |

67.9 |

1131 |

0.6 |

950 |

15.5 |

18.5 |

5.5 |

| 65.4 |

1090 |

1.0 |

24.5 |

30 |

| 108 |

1802 |

0.6 |

1450 |

24.7 |

30 |

| 105 |

1760 |

1.0 |

38.2 |

45 |

| 120*2-46 |

79.6 |

1327 |

0.6 |

950 |

17.8 |

22 |

5.5 |

| 77.2 |

1285 |

1.0 |

28.2 |

37 |

| 126 |

2101 |

0.6 |

1450 |

28.5 |

37 |

| 123 |

2059 |

1.0 |

44.1 |

55 |

| 150*2-46 |

158 |

2640 |

0.6 |

950 |

34.6 |

45 |

5.5 |

| 154 |

2582 |

1.0 |

54.5 |

75 |

| 241.7 |

4029.7 |

0.6 |

1450 |

53.8 |

7590 |

| 236.5 |

3942.2 |

1.0 |

82.2 |

.jpg)

.jpg)

(2).png)

.jpg)