.jpg)

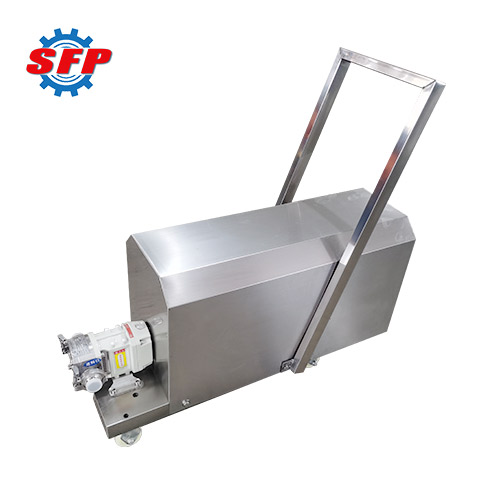

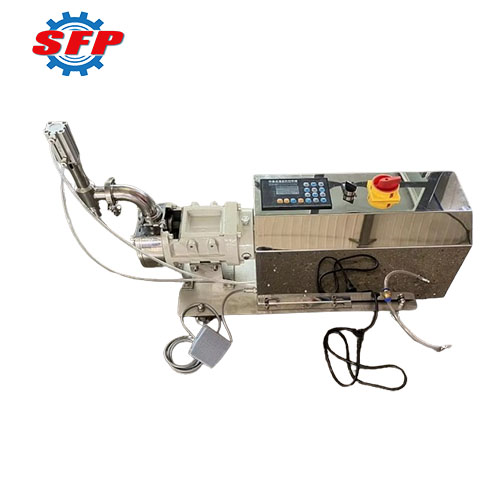

3RP series lobe filling pump is a multi-purpose two-way positive displacement pump produced by our company with advanced technology from Germany. It can be used to handle suspensions containing solid particles, corrosive media and hygienic media, the temperature range of the conveyed media is -30~180℃, and the viscosity range is 30cst~100000cst. Furthermore, the pump has a stable flow rate and pressure output, which can satisfy the needs of different working conditions, and so it can be used in daily-use chemical industry, building materials, pharmaceutical industry, petroleum industry, and food and beverage processing industry.

%20(1).png)

.png)

(1).png)

(22).png)

|

Model |

Flow |

Pressure |

Rev |

Power |

Inlet/outlet size |

|

|

(L/100r) |

(m³/h) |

(Mpa) |

(rpm) |

(kW) |

(mm) |

|

|

3RP-25 |

6 |

≤1.8 |

0-1.0 |

≤600 |

0.75 |

25 |

|

3RP-32 |

9 |

≤2.7 |

0-1.0 |

1.1 |

32 |

|

|

3RP-40 |

18 |

≤4.3 |

0.-1.0 |

1.5 |

40 |

|

|

3RP-50 |

36 |

≤8.6 |

0-1.0 |

2.2 |

50 |

|

|

3RP-65 |

60 |

≤14.4 |

0-1.0 |

4 |

65 |

|

|

3RP-80 |

105 |

≤25.2 |

0-1.0 |

11 |

80 |

|

|

3RP-100A |

125 |

≤30 |

0-1.0 |

15 |

100 |

|

|

3RP-100 |

150 |

≤36 |

0-1.0 |

18.5 |

100 |

|

|

3RP-125 |

250 |

≤60 |

0-1.0 |

22 |

125 |

|

.jpg)