.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

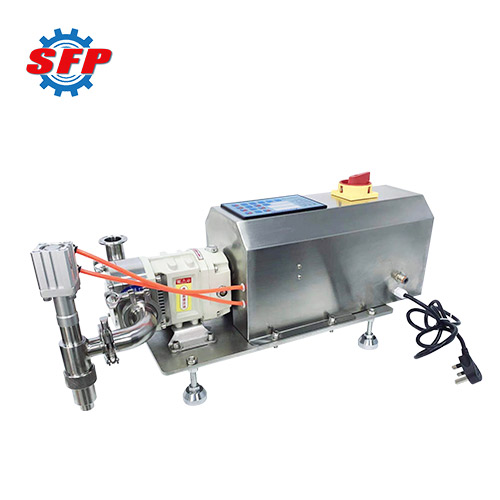

3RP lobe filling machine is applied to fill corrosive and suspended high viscosity liquids such as honey, sauces, skin creams, laundry detergents, edible oils and so on. It can be used in food factories, daily use factories, beverage factories, petroleum factories, chemical factories, pharmaceutical factories and other applications. This pump adopts advanced metering system and control technology, which can realize high-precision liquid filling and ensure the accurate and consistent amount of liquid in each packaging container.

3RP series lobe filling pump is mainly composed of rotor, shaft seal, gear box, a pair of synchronous meshing of the active gear, to achieve the delivery of the medium. Adopted is the gear transmission mode, the main shaft and auxiliary shaft drive the rotor synchronous reverse rotation, so that the pump volume changes, thus forming a higher vacuum and discharge pressure, so it is specially designed for sanitary media and strong corrosive high-viscosity media.

.jpg)

.jpg)

1. If necessary, the pump can be made with heating jacket.

2. It can convey gas, liquid and solid three-phase mixture materials.

3. There is a certain gap between rotor and rotor, no friction coefficient, long service life.

4. Simple installation and dismantling, easy maintenance and cleaning, few wearing parts.

5. Import and export connection type: flange connection, threaded connection, quick connection.

6. High efficiency and energy saving, smooth conveying, low failure rate, sealing without leakage, low noise.

7. The viscosity of conveying medium is ≤2,000,000cp, and the slurry containing 70% solids can be conveyed.

8. Equipped with frequency converter, the flow rate can be adjusted arbitrarily, and it can be used as a general metering pump.

|

Model |

Flow |

Pressure |

Rev |

Power |

Inlet/Outlet Size |

|

|

(L/100r) |

(m³/h) |

(Mpa) |

(rpm) |

(kW) |

(mm) |

|

|

3RP-25 |

6 |

≤1.8 |

0-1.0 |

≤600 |

0.75 |

25 |

|

3RP-32 |

9 |

≤2.7 |

0-1.0 |

1.1 |

32 |

|

|

3RP-40 |

18 |

≤4.3 |

0.-1.0 |

1.5 |

40 |

|

|

3RP-50 |

36 |

≤8.6 |

0-1.0 |

2.2 |

50 |

|

|

3RP-65 |

60 |

≤14.4 |

0-1.0 |

4 |

65 |

|

|

3RP-80 |

105 |

≤25.2 |

0-1.0 |

11 |

80 |

|

|

3RP-100A |

125 |

≤30 |

0-1.0 |

15 |

100 |

|

|

3RP-100 |

150 |

≤36 |

0-1.0 |

18.5 |

100 |

|

|

3RP-125 |

250 |

≤60 |

0-1.0 |

22 |

125 |

|