.jpg)

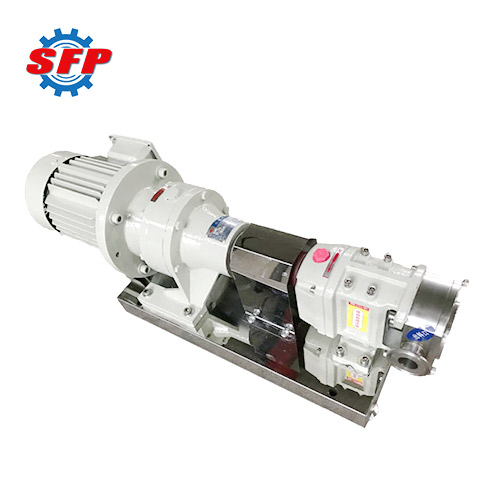

3RP series lobe pump is a multi-purpose double-direction positive displacement pump produced by our company with the introduction of advanced technology from Germany, and the professional manufacturing technology and manufacturing precision of the product are close to those of the similar products from Germany. The pump is commonly applied to the transportation of suspensions containing soft solid particles, corrosive media and suspensions in the daily chemical, petroleum, food and beverage industries.

3RP series rotary lobe pump is made up of rotor, shaft seal, gear box, a pair of synchronized meshing active gear, driving the rotor to transport media. Adopted is the gear transmission mode, the main shaft and auxiliary shaft drive the rotor synchronous reverse rotation, so that the pump volume changes, thus forming a higher vacuum and discharge pressure, so it is particularly suitable for sanitary media and strong corrosive high-viscosity media. In further, the pump adopts high-strength cast iron gearboxes, helical gears and heavy-duty bearings to ensure long-term operation of the pump.

(7).png)

(8).png)

1. Foodstuffs: Chocolate, condensed milk, yogurt, honey, syrup, cane sugar, tomato juice, fruit juice concentrate, jam, ice cream, milk, yeast slurry, jelly, condiments, flour slurry and so on.

2. Daily chemicals: Detergent, laundry detergent, shower gel, skin cream, shampoo, hand soap, toothpaste, soap, laundry detergent slurry, daily chemical raw materials.

3. Paper-making: Polyacrylamide, calcium carbonate, starch paste, rosin, pulp, filler, dry strength agent, wet strength agent, coating, water treatment chemicals, etc.

4. Pharmaceuticals: Various ointments, medicinal emulsions, syrups, health products, pharmaceuticals, etc.

5. Fine chemicals: Dyes, pigments, adhesives, leather oil, various colloidal materials, various pastes, etc.

6. Coatings: Paints, coatings, inks, insulating paints, resins, auxiliaries, organic solvents, etc.

7. Chemical fiber: Polyester, polypropylene, synthetic fiber, functional dimension, etc.

(13).png)

| Model | Flow | Discharge Pressure (Mpa) |

Rev (rpm) |

Motor Power (kw) |

Inlet/Outlet (mm) |

|

| L/100r | m³/h | |||||

| 3RP-25 | 6 | ≤1.8 | 0-1.0 | 10-400 | 0.75 | 25 |

| 3RP-32 | 9 | ≤2.7 | 1.1 | 32 | ||

| 3RP-40 | 18 | ≤4.3 | 1.5 | 40 | ||

| 3RP-50 | 36 | ≤8.6 | 2.2 | 50 | ||

| 3RP-65 | 60 | ≤14.4 | 4 | 65 | ||

| 3RP-80 | 105 | ≤25.2 | 11 | 80 | ||

| 3RP-100A | 125 | ≤30 | 15 | 100 | ||

| 3RP-100 | 150 | ≤36 | 18.5 | 100 | ||

| 3RP-125 | 250 | ≤60 | 22 | 125 | ||