.jpg)

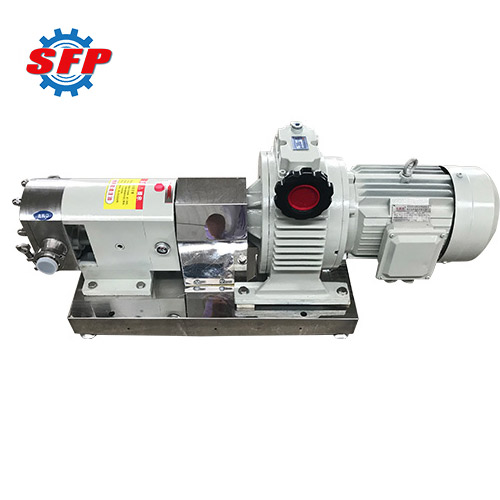

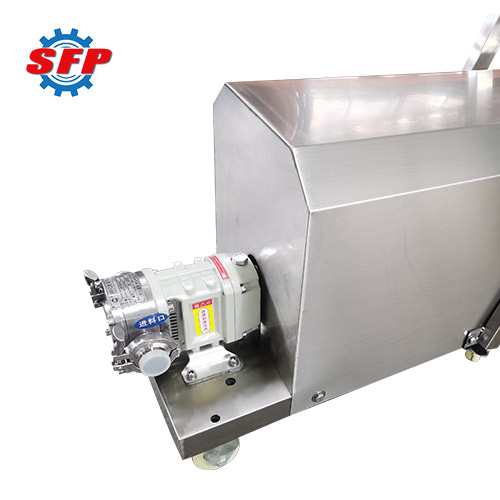

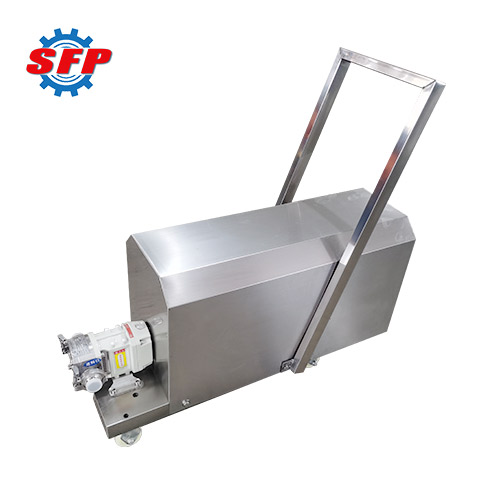

3RP series mobile rotary lobe pump is a volumetric pump, suitable for conveying temperature -30℃~180℃, viscosity 30~1.0x10⁵cSt, suspended liquids containing solid particles, and corrosive and hygienic requirements of high media. This machine adopts materials with reliable anti-rust performance and non-toxic sealing performance, which can ensure the safety and hygiene of the production process. Hence, it is also the preferred equipment for food, beverage, chemical, daily necessities, petroleum and other industries.

(8).png)

(9).png)

(10).png)

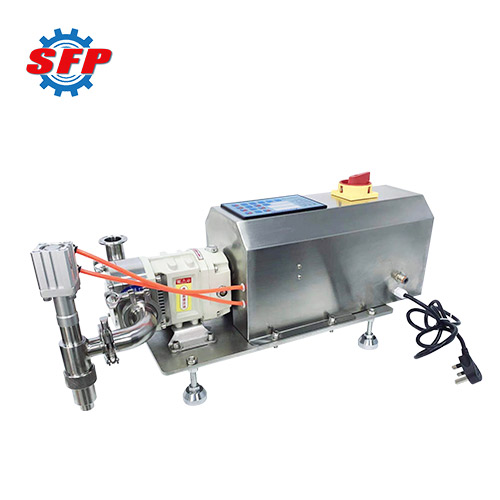

1. This equipment can transport high-viscosity, high-concentration, and other materials with poor fluidity, as well as gases, liquids, solid-liquid mixtures, and a variety of other materials.

2. It rotors and the pump body can maintain a certain gap between them, ensuring no contact and no friction, which results in a long service life.

3. This pump has a reasonable structural design, making installation, disassembly, and maintenance more convenient.

| Model | Flow | Discharge Pressure (Mpa) |

Rev (rpm) |

Motor Power (kw) |

Inlet/Outlet (mm) |

|

| L/100r | m³/h | |||||

| 3RP-25 | 6 | ≤1.8 | 0-1.0 | 10-400 | 0.75 | 25 |

| 3RP-32 | 9 | ≤2.7 | 1.1 | 32 | ||

| 3RP-40 | 18 | ≤4.3 | 1.5 | 40 | ||

| 3RP-50 | 36 | ≤8.6 | 2.2 | 50 | ||

| 3RP-65 | 60 | ≤14.4 | 4 | 65 | ||

| 3RP-80 | 105 | ≤25.2 | 11 | 80 | ||

| 3RP-100A | 125 | ≤30 | 15 | 100 | ||

| 3RP-100 | 150 | ≤36 | 18.5 | 100 | ||

| 3RP-125 | 250 | ≤60 | 22 | 125 | ||