.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

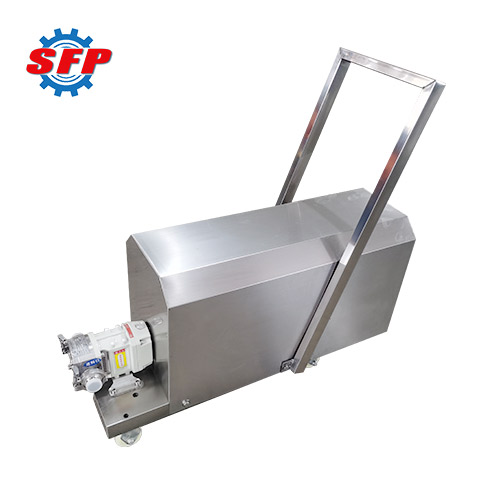

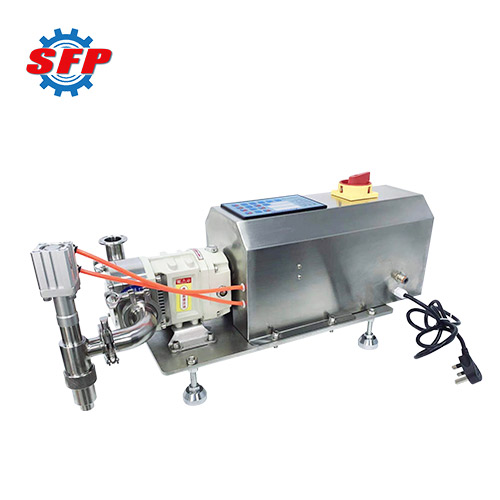

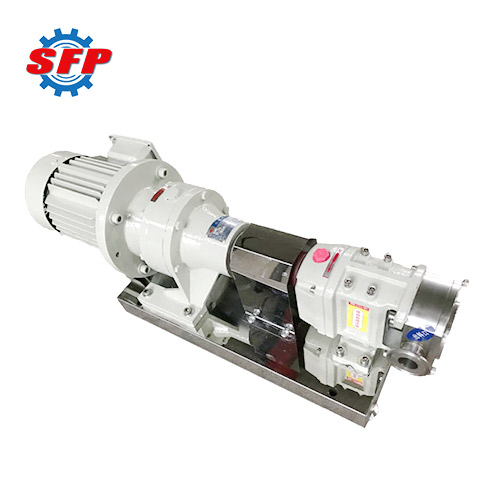

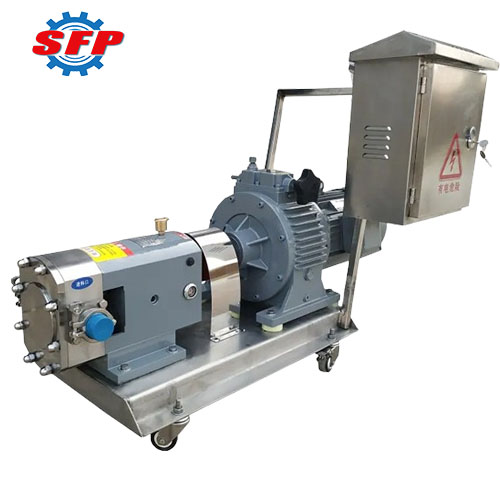

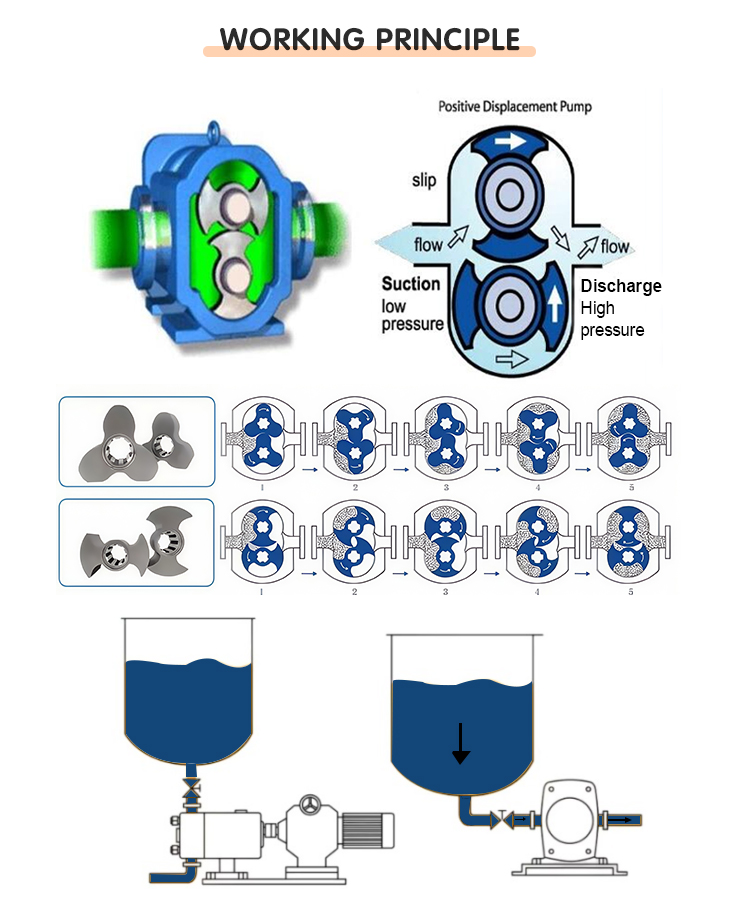

3RP series mobile lobe pump belongs to positive displacement pump, which has the advantages of strong self-priming ability, high efficiency and long service life. The pump is capable of handling suspensions containing solid particles, corrosive media, and suspensions, and the temperature range of the conveyed medium is -30~180 ℃, and the viscosity range is 30 cst~100000 cst. At the same time, the parts contacting with the medium are made of stainless steel, which prevents the medium from being contaminated in the process of conveying.

It is mainly composed of rotor, shaft seal, gear box, a pair of synchronous meshing of the active gear, driving the rotor to transport media. Adopted is the gear transmission mode, the main shaft and auxiliary shaft drive the rotor synchronous reverse rotation, so that the pump volume changes, thus forming a higher vacuum and discharge pressure, so especially suitable for sanitary media and highly corrosive high viscosity media. In addition, the pump utilizes a high-strength cast iron gearbox, helical gears and heavy-duty bearings to ensure long-term pump operation.

.jpg)

|

Model |

Flow (L/100r) |

Discharge Pressure (bar) |

Inlet/Outlet (mm) |

Rev (r/min) |

Medium Viscosity (cp) |

|

3rp-25 |

12.5 |

≤10 |

25 |

≤600 |

1-2000000 |

|

3rp-40 |

21 |

≤10 |

40 |

≤600 |

1-2000000 |

|

3rp-50 |

52 |

≤10 |

50 |

≤600 |

1-2000000 |

|

3rp-80 |

107 |

≤10 |

80 |

≤600 |

1-2000000 |

|

3rp-100 |

156 |

≤10 |

100 |

≤600 |

1-2000000 |

|

3rp-125 |

680 |

≤10 |

125 |

≤600 |

1-2000000 |

|

3rp-150 |

1280 |

≤10 |

150 |

≤600 |

1-2000000 |

|

3rp-200 |

2000 |

≤10 |

200 |

≤600 |

1-2000000 |

|

3rp-250 |

3000 |

≤10 |

250 |

≤600 |

1-2000000 |

|

3rp-300 |

4000 |

≤10 |

300 |

≤600 |

1-2000000 |