.jpg)

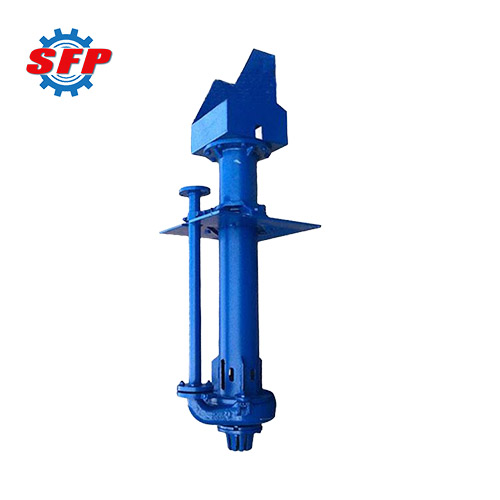

YZ series single stage vertical slurry pump is mainly used to pump sand, slurry and other media containing solid particles, in mining, metallurgy, construction, water conservancy and other industries of sand, slag and other operations play an important role. And by virtue of its stable operation, reasonable design and stable operation, it has become the first choice for high-temperature kerosene, crude oil, asphalt, oil slag and other slurries.

1. It features a single-stage, single-suction cantilevered structure, and the pump's hydraulic components are connected via the bearing housing, support base, and connecting piping, with discharge achieved through the outlet pipe.

2. The shaft seal employs an immersion pump design, with the seal fully submerged in the liquid, eliminating the need for a separate shaft seal assembly.

3. It drive assembly is mounted on the motor bracket and support base via a vertical motor, connected to the pump body through a coupling.

4. The pump body utilizes an integral cast structure, ensuring structural integrity and reliable sealing.

.jpg)