.jpg)

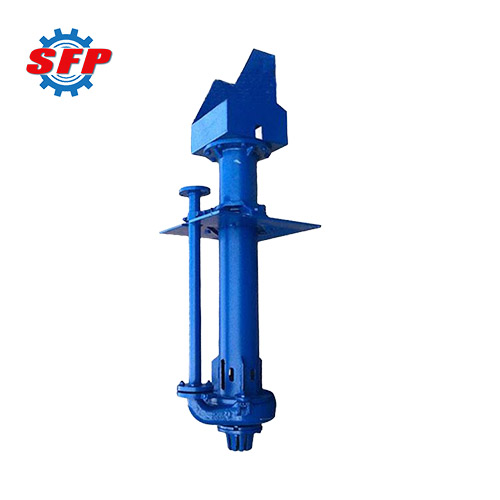

ZJQ series submersible slurry pump is an ideal product to replace the traditional vertical submerged pump and submersible sewage pump. Especially suitable for metallurgy, mining, environmental protection, power plants and other industries to transport sand, cinder, tailings, sludge, slurry and other light corrosive media with solid particles. The structure of the pump is reasonably designed, and the parts have passed strict quality testing, long service life, long-term safe operation under adverse working conditions.

| Model | Diameter (mm) |

Flow (m³/h) |

Head (m) |

Power (kw) |

Speed (r/min) |

Discontinuous Maximum Particle Size (mm) |

Weight (kg) |

| ZJQ45-15-5.5 | 80 | 45 | 15 | 5.5 | 1460 | 13 | 100 |

| ZJQ15-20-5.5 | 80 | 15 | 20 | 5.5 | 1460 | 13 | 100 |

| ZJQ50-10-5.5 | 80 | 50 | 10 | 5.5 | 1460 | 13 | 100 |

| ZJQ15-20-7.5 | 80 | 15 | 20 | 7.5 | 1460 | 13 | 114 |

| ZJQ20-15-7.5 | 80 | 20 | 15 | 7.5 | 1460 | 13 | 114 |

| ZJQ25-20-7.5 | 80 | 25 | 20 | 7.5 | 1460 | 13 | 114 |

| ZJQ25-30-7.5 | 80 | 25 | 30 | 7.5 | 1460 | 13 | 114 |

| ZJQ30-30-7.5 | 80 | 30 | 30 | 7.5 | 1460 | 13 | 114 |

| ZJQ32-20-7.5 | 80 | 32 | 20 | 7.5 | 1460 | 13 | 114 |

| ZJQ40-15-7.5 | 80 | 40 | 15 | 7.5 | 1460 | 13 | 114 |

| ZJQ100-10-7.5 | 100 | 100 | 10 | 7.5 | 1460 | 21 | 165 |

| ZJQ25-40-11 | 80 | 25 | 40 | 11 | 1460 | 13 | 300 |

| ZJQ40-25-11 | 80 | 40 | 25 | 11 | 1460 | 13 | 165 |

| ZJQ50-21-11 | 80 | 50 | 21 | 11 | 1460 | 13 | 165 |

| ZJQ50-26-11 | 80 | 50 | 26 | 11 | 1460 | 13 | 165 |

| ZJQ70-20-11 | 80 | 70 | 20 | 11 | 1460 | 13 | 165 |

| ZJQ100-18-11 | 100 | 100 | 18 | 11 | 1460 | 21 | 217 |

| ZJQ25-40-15 | 80 | 25 | 40 | 15 | 1460 | 13 | 330 |

| ZJQ50-26-15 | 80 | 50 | 26 | 15 | 1460 | 13 | 180 |

| ZJQ50-28-15 | 80 | 50 | 28 | 15 | 1460 | 13 | 180 |

| ZJQ60-30-15 | 100 | 60 | 30 | 15 | 1460 | 13 | 220 |

| ZJQ70-24-15 | 80 | 70 | 24 | 15 | 1460 | 13 | 180 |

| ZJQ75-25-15 | 100 | 75 | 25 | 15 | 1460 | 13 | 220 |

| ZJQ100-18-15 | 100 | 100 | 18 | 15 | 1460 | 21 | 250 |

| ZJQ150-15-15 | 100 | 150 | 15 | 15 | 1460 | 21 | 250 |

| ZJQ150-18-18.5 | 150 | 150 | 18 | 18.5 | 980 | 32 | 550 |

| ZJQ200-12-18.5 | 150 | 200 | 12 | 18.5 | 980 | 45 | 550 |

| ZJQ150-22-22 | 150 | 150 | 22 | 22 | 980 | 32 | 580 |

| ZJQ200-15-22 | 150 | 200 | 15 | 22 | 980 | 45 | 580 |

| ZJQ60-46-30 | 150 | 60 | 46 | 30 | 980 | 21 | 700 |

| ZJQ70-38-30 | 150 | 70 | 38 | 30 | 980 | 21 | 550 |

| ZJQ100-35-30 | 150 | 100 | 35 | 30 | 980 | 21 | 550 |

| ZJQ108-30-30 | 150 | 108 | 30 | 30 | 980 | 21 | 550 |

| ZJQ150-30-30 | 150 | 150 | 30 | 30 | 980 | 21 | 550 |

| ZJQ150-35-30 | 150 | 150 | 35 | 30 | 980 | 21 | 550 |

| ZJQ200-20-30 | 150 | 200 | 20 | 30 | 980 | 21 | 550 |

| ZJQ240-20-30 | 150 | 240 | 20 | 30 | 980 | 21 | 550 |

| ZJQ300-15-30 | 200 | 300 | 15 | 30 | 980 | 28 | 700 |

| ZJQ100-50-37 | 150 | 100 | 50 | 37 | 980 | 21 | 850 |

| ZJQ300-20-37 | 200 | 300 | 20 | 37 | 980 | 28 | 775 |

| ZJQ400-15-37 | 200 | 400 | 15 | 37 | 980 | 28 | 775 |

| ZJQ150-30-45 | 150 | 150 | 30 | 45 | 980 | 36 | 1000 |

| ZJQ200-30-45 | 150 | 200 | 30 | 45 | 980 | 36 | 1000 |

| ZJQ500-15-45 | 250 | 500 | 15 | 45 | 980 | 46 | 1100 |

| ZJQ150-45-55 | 150 | 150 | 45 | 55 | 980 | 21 | 1140 |

| ZJQ250-35-55 | 150 | 250 | 35 | 55 | 980 | 36 | 1140 |

| ZJQ600-15-55 | 250 | 600 | 15 | 55 | 980 | 46 | 1140 |

| ZJQ200-45-75 | 150 | 200 | 45 | 75 | 980 | 21 | 1540 |

| ZJQ350-35-75 | 200 | 350 | 35 | 75 | 980 | 28 | 1550 |

| ZJQ400-25-75 | 200 | 400 | 25 | 75 | 980 | 25 | 1550 |

| ZJQ500-20-75 | 200 | 500 | 20 | 75 | 980 | 25 | 1550 |

| ZJQ200-50-75 | 150 | 200 | 50 | 75 | 980 | 14 | 1500 |

| ZJQ200-60-90 | 150 | 200 | 60 | 90 | 980 | 14 | 1550 |

| ZJQ400-40-90 | 200 | 400 | 40 | 90 | 980 | 28 | 1550 |

| ZJQ500-25-90 | 200 | 500 | 25 | 90 | 980 | 25 | 1550 |

| ZJQ400-50-110 | 200 | 400 | 50 | 110 | 980 | 28 | 1970 |

| ZJQ600-30-110 | 200 | 600 | 30 | 110 | 980 | 28 | 1970 |

| ZJQ780-26-110 | 300 | 780 | 26 | 110 | 980 | 50 | 1970 |

| ZJQ1000-18-110 | 300 | 1000 | 18 | 110 | 980 | 50 | 1970 |

| ZJQ400-60-132 | 200 | 400 | 60 | 132 | 980 | 28 | 2000 |

| ZJQ500-45-132 | 200 | 500 | 45 | 132 | 980 | 28 | 2000 |

| ZJQ500-55-132 | 200 | 500 | 55 | 132 | 980 | 28 | 2000 |

| ZJQ800-35-132 | 300 | 800 | 35 | 132 | 980 | 42 | 2000 |

| ZJQ1000-22-132 | 300 | 1000 | 22 | 132 | 980 | 50 | 2000 |

| ZJQ650-52-160 | 200 | 650 | 52 | 160 | 980 | 28 | 2650 |

| ZJQ780-50-185 | 300 | 780 | 50 | 185 | 980 | 38 | 3330 |

| ZJQ800-55-220 | 300 | 800 | 55 | 220 | 980 | 38 | 3400 |

| ZJQ1250-35-220 | 350 | 1250 | 35 | 220 | 980 | 45 | 3400 |

| ZJQ1750-30-250 | 350 | 1750 | 30 | 250 | 980 | 55 | 3500 |

| ZJQ1500-35-250 | 350 | 1500 | 35 | 250 | 980 | 50 | 3500 |

| ZJQ2000-35-315 | 400 | 2000 | 35 | 315 | 980 | 60 | 3700 |