.png)

.png)

.png)

.jpg)

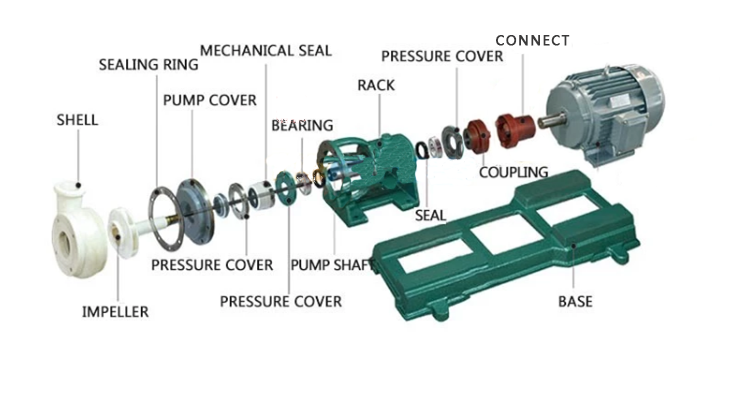

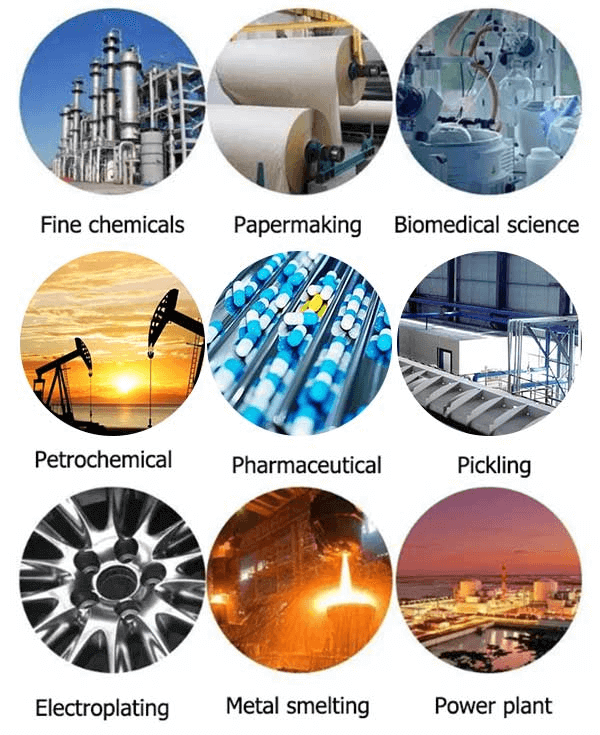

FSB series chemical centrifugal pump is a kind of fluoroplastic alloy centrifugal pump, specially designed for dealing with various corrosive and abrasive media, which can transport various acidic, oxidizing, corrosive and other media with physical properties similar to water for a long time. The equipment integrates the advantages of fluoroplastics, featuring strong corrosion resistance, high mechanical strength, compact structure and reliable performance. Therefore, it can be suitable for conveying liquids in pharmaceutical, chemical, petroleum, pickling, dyestuff, paint, smelting, papermaking, electroplating, and other industries.

| Model | Flow (m³/h) |

Lift (m) |

Motor Power (kw) |

Speed (r/min) |

NPSH (m) |

Efficiency (%) |

| 25FSB-25(D) | 3 | 25 | 1.5 | 2900 | 3 | 20 |

| 40FSB-15(D) | 5 | 15 | 1.5 | 2900 | 3 | 40 |

| 40FSB-20(D) | 10 | 20 | 2.2 | 2900 | 3 | 42 |

| 40FSB-30(D) | 10 | 30 | 3 | 2900 | 3 | 52 |

| 50FSB-20(D) | 12.5 | 20 | 3 | 2900 | 3.5 | 55 |

| 50FSB-25(D) | 12.5 | 25 | 3 | 2900 | 3.5 | 55 |

| 50FSB-30(D) | 15 | 30 | 4 | 2900 | 3.5 | 54 |

| 65FSB-32(D) | 25 | 32 | 5.5 | 2900 | 3.5 | 65 |

| 80FSB-20(D) | 50 | 20 | 5.5 | 2900 | 3 | 55 |

| 80FSB-25(D) | 50 | 25 | 5.5 | 2900 | 3.5 | 67 |

| 80FSB-32(D) | 50 | 32 | 7.5 | 2900 | 3.5 |