.jpg)

.jpg)

.jpg)

.jpg)

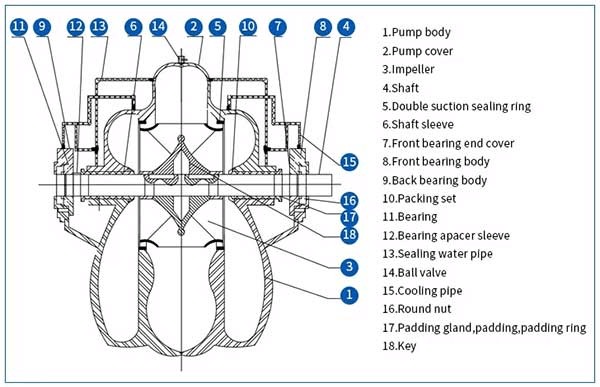

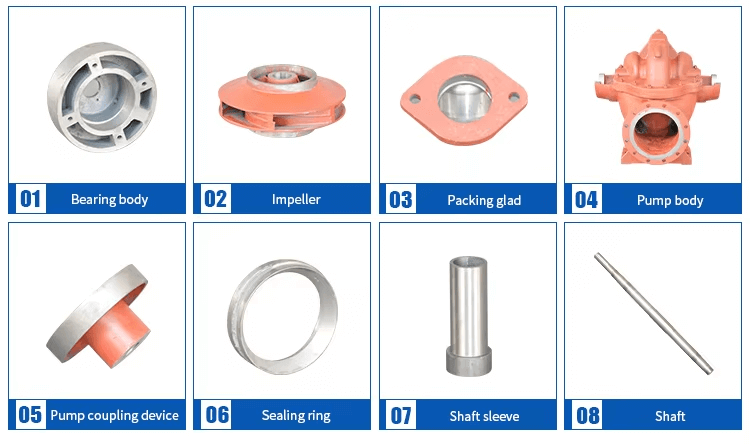

S/SH series single-stage double-suction centrifugal pumps are suitable for conveying clear water and liquids with physicochemical properties similar to water. By virtue of its high head and large flow rate, so it is also ideal for drainage of mines, cities and power stations, farmland irrigation and various water conservancy projects. What's more, this pump adopts smooth and optimized design of double suction impeller, and minimum hydraulic performance and significant impact resistance characteristics.

| Model | Q (m³/h) |

H (m) |

n (r/min) |

Power (KW) | η (%) |

NPSH (m) |

|

| Shaft | Motor | ||||||

| 100S90 | 80 | 90 | 2950 | 30.1 | 37 | 65 | 2.5 |

| 100S90A | 72 | 75 | 23 | 30 | 64 | 2.5 | |

| 150S100 | 160 | 100 | 59.8 | 75 | 73 | 3.5 | |

| 150S78 | 160 | 78 | 45 | 55 | 73.5 | 3.5 | |

| 150S78A | 144 | 62 | 33.8 | 45 | 72 | 3.5 | |

| 150S50 | 160 | 50 | 27.3 | 37 | 80 | 3.9 | |

| 150S50A | 144 | 40 | 20.9 | 30 | 75 | 3.9 | |

| 150S50B | 133 | 36 | 18.6 | 22 | 70 | 3.9 | |

| 200S95 | 280 | 95 | 91.7 | 110 | 79.2 | 5.3 | |

| 200S95A | 270 | 75 | 73.5 | 90 | 75 | 5.3 | |

| 200S63 | 280 | 63 | 58.3 | 75 | 82.7 | 5.8 | |

| 200S63A | 270 | 46 | 45.1 | 55 | 75 | 5.8 | |

| 200S42 | 280 | 42 | 38.1 | 45 | 84.2 | 6 | |

| 200S42A | 270 | 36 | 33.1 | 37 | 80 | 6 | |

| 250S65 | 485 | 65 | 1450 | 109 | 132 | 78.6 | 3 |

| 250S65A | 468 | 54 | 89.4 | 110 | 77 | 3 | |

| 250S39 | 485 | 39 | 61.5 | 75 | 83.6 | 3.2 | |

| 250S39A | 468 | 30.5 | 49.3 | 55 | 79 | 3.2 | |

| 250S24 | 485 | 24 | 36.9 | 45 | 85.8 | 3.5 | |

| 250S24A | 414 | 20.3 | 27.6 | 37 | 83 | 3.5 | |

| 250S14 | 485 | 14 | 21.5 | 30 | 85.8 | 3.8 | |

| 250S14A | 432 | 11 | 15.8 | 18.5 | 82 | 3.8 | |

| 300S110 | 790 | 110 | 295.7 | 440 | 80 | 4 | |

| 300S90 | 790 | 90 | 242.8 | 315 | 79.6 | 4 | |

| 300S90A | 756 | 78 | 217 | 280 | 74 | 4 | |

| 300S90B | 720 | 67 | 180 | 220 | 73 | 4 | |

| 300S58 | 790 | 58 | 149.9 | 180 | 84.2 | 4.4 | |

| 300S58A | 720 | 49 | 118.6 | 160 | 81 | 4.4 | |

| 300S58B | 684 | 43 | 100 | 132 | 80 | 4.4 | |

| 300S32 | 790 | 32 | 79.2 | 110 | 86.8 | 4.6 | |

| 300S32A | 720 | 26 | 60.7 | 75 | 84 | 4.6 | |

| 300S19 | 790 | 19 | 47 | 55 | 86.8 | 5.2 | |

| 300S19A | 720 | 16 | 39.2 | 45 | 80 | 5.2 | |

| 300S12 | 790 | 12 | 30.4 | 37 | 84.8 | 5.5 | |

| 300S12A | 684 | 10 | 3.9 | 30 | 78 | 5.5 | |

| 350S125 | 1260 | 125 | 534 | 710 | 80.5 | 5.4 | |

| 350S125A | 1181 | 112 | 462 | 630 | 78 | 5.4 | |

| 350S125B | 1098 | 96 | 373 | 500 | 77 | 5.4 | |

| 350S75 | 1260 | 75 | 303 | 355 | 85.2 | 5.8 | |

| 350S75A | 1170 | 65 | 247 | 280 | 84 | 5.8 | |

| 350S75B | 1080 | 55 | 197 | 220 | 82 | 5.8 | |

| 350S44 | 1260 | 44 | 173 | 220 | 87.5 | 6.3 | |

| 350S44A | 1116 | 36 | 131 | 160 | 84 | 6.3 | |

| 350S26 | 1260 | 26 | 102 | 132 | 87.5 | 6.7 | |

| 350S26A | 1116 | 21.5 | 78.8 | 90 | 83 | 6.7 | |

| 350S16 | 1260 | 16 | 64.5 | 75 | 85.3 | 7.1 | |

| 350S16A | 1044 | 13.4 | 48.8 | 55 | 48 | 7.1 | |

| 500S98 | 2020 | 95 | 970 | 678 | 800 | 79.5 | 4 |

| 500S98A | 1872 | 83 | 540 | 630 | 78.5 | 4 | |

| 500S98B | 1746 | 74 | 452 | 560 | 78 | 4 | |

| 500S59 | 2020 | 59 | 391 | 450 | 83 | 4.5 | |

| 500S59A | 1872 | 49 | 333 | 400 | 75 | 4.5 | |

| 500S59B | 1746 | 40 | 257 | 315 | 74 | 4.5 | |

| 500S35 | 2020 | 35 | 219 | 280 | 88 | 4.8 | |

| 500S35A | 1746 | 27 | 151 | 220 | 85 | 4.8 | |

| 500S22 | 2020 | 22 | 144.1 | 185 | 84 | 5.2 | |

| 500S22A | 1746 | 17 | 101 | 132 | 80 | 5.2 | |

| 500S13 | 2020 | 13 | 86.2 | 110 | 83 | 5.7 | |

| 600S75 | 3170 | 75 | 727 | 800 | 89 | 7.5 | |

| 600S75A | 2880 | 65 | 580 | 630 | 88 | 7.5 | |

| 600S47 | 3170 | 47 | 465 | 560 | 88 | 7.5 | |

| 600S32 | 3170 | 32 | 310 | 400 | 89 | 7.5 | |

| 600S32A | 2880 | 27 | 238 | 280 | 89 | 7.5 | |

| 600S22 | 3170 | 22 | 223 | 280 | 85 | 7.5 | |

| 600S22A | 2880 | 18.2 | 168.5 | 200 | 84.5 | 7.5 | |