.jpg)

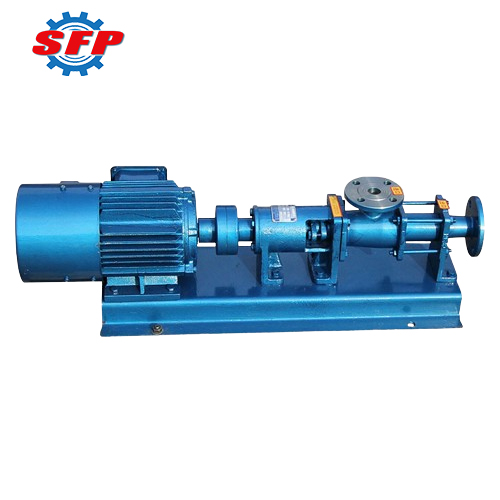

G series slurry screw pump can not only convey various fluid media, but also handle high viscosity media, media containing hard suspended particles or solid particles. It is usually widely used in shipbuilding, petroleum, food, construction, chemical, paper making, power plant and other industries. The pump is equipped with stable conveying, adjustable pressure, compact structure, reasonable design, long service life, low noise and so on.

(3).png)

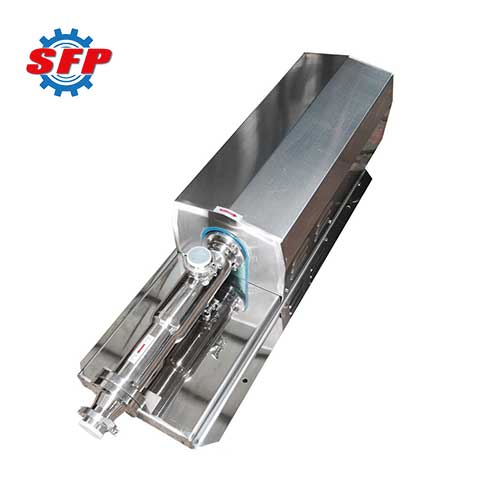

(1).png)

.png)

| Model | Flow (m³/h) |

Pressure (MPa) |

Speed (r/min) |

Motor Power (kw) |

Inlet/Outsize Size (mm) |

Max Solid Size (mm) |

Max Fiber Length (mm) |

| G10-1 | 0.1 | 0.6 | 960 | 0.55 | 25 | 0.8 | 15 |

| G10-2 | 1.2 | 0.55 | 25 | ||||

| G13-1 | 0.4 | 0.6 | 960 | 0.55 | 25 | 0.8 | 15 |

| G13-2 | 1.2 | 0.55 | 25 | ||||

| G15-1 | 0.6 | 0.6 | 960 | 0.55 | 25 | 1 | 20 |

| G15-2 | 1.2 | 0.75 | 25 | ||||

| G20-1 | 0.8 | 0.6 | 960 | 0.75 | 25 | 1.5 | 25 |

| G20-2 | 0.6 | 1.1 | 25 | ||||

| G25-1 | 2 | 0.6 | 960 | 1.5 | 32 | 2 | 30 |

| G25-2 | 1.2 | 2.2 | 32 | ||||

| G30-1 | 5 | 0.6 | 960 | 2.2 | 50 | 2.5 | 30 |

| G30-2 | 1.2 | 3 | 50 | ||||

| G35-1 | 8 | 0.6 | 960 | 3 | 65 | 3 | 40 |

| G35-2 | 1.2 | 4 | 65 | ||||

| G40-1 | 12 | 0.6 | 960 | 4 | 80 | 3.8 | 45 |

| G40-2 | 1.2 | 5.5 | 80 | ||||

| G50-1 | 20 | 0.6 | 960 | 5.5 | 100 | 5 | 50 |

| G50-2 | 1.2 | 7.5 | 100 | ||||

| G60-1 | 30 | 0.6 | 960 | 11 | 125 | 6 | 60 |

| G60-2 | 1.2 | 15 | 125 | ||||

| G70-1 | 45 | 0.6 | 720 | 11 | 150 | 8 | 70 |

| G70-2 | 1.2 | 18.5 | |||||

| G85-1 | 65 | 0.6 | 720 | 15 | 150 | 10 | 80 |

| G85-2 | 0.6 | 30 | |||||

| G105-1 | 80 | 0.6 | 720 | 22 | 200 | 10 | 80 |

| G135-1 | 100 | 0.6 | 720 | 30 | 200 | 10 | 80 |