Summarize:

.jpg)

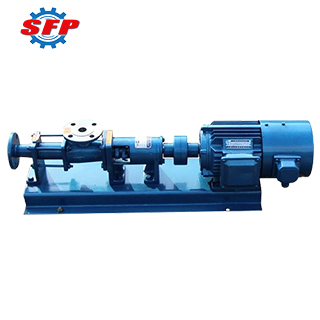

G series screw slurry pumps are mainly used for conveying high viscosity media and media containing solid particles, abrasive particles, fibers, and can also be used to handle neutral or corrosive media. Widely used in various industrial sectors, such as dirt treatment, chemical industry, paper industry, ceramic industry, exploration and mining, food chemical and so on. The machine can also be customized according to customer requirements in the feed port special hopper, to maintain the smoothness of the feed, to achieve the feed, discharge without pressure, so that its conveying efficiency and longer service life.

Application:

1. Environmental Protection: industrial sewage, domestic sewage, and sludge turbid water containing solid particles and short fibers are especially used in oil-water separator plate and frame filter press equipment.

2. Petroleum Industry: transporting crude oil, a mixture of crude oil and water, a mixture of coal gas and water, pouring polymers into the formation.

3. Food Canning Industry: all kinds of viscous starch, distiller's grains, grain slag, various sauces, pulp, solid slurry.

4. Printing: high viscosity ink, wallpaper PVC polymer paste and various concentrations of pulp, short fiber slurry.

5. Shipbuilding Industry: round bottom cleaning, oil water, oil residue, oil sewage and other ring transportation.

6. Chemical Industry: various suspensions, greases, various colloidal pastes, various adhesives.

7. Construction Industry: spraying of cement mortar, lime slurry, paint and paste.

Feature:

The flow rate of this pump screw is proportional to the rotational speed, and it can be driven directly by coupling drive, or variable speed by speed-regulating motor, delta belt, gear box and other devices. This kind of pump has few parts, compact structure, small volume, simple maintenance, rotor and stator are the wearing parts of the pump, simple structure, easy to install and dismantle.

1. With stepless speed regulation, can be customized according to the requirements of electromagnetic speed control.

2. With sanitary standard, all stainless steel polishing treatment, cart funnel can be customized.

3. Insensitive to incoming gas and dirt compared to other rotary pumps.

4. Wide range of liquid types and viscosity that can be conveyed.

5. Uniform and continuous flow, low vibration and low noise.

Performance Data:

| Model |

Flow (m3/h) |

Pressure

(MPa) |

Speed (r/min) |

Motor power

(kw) |

Inlet/Outsize Size

(mm) |

Max Solid Size

(mm) |

| G10-1 |

0.1 |

0.6 |

960 |

0.55 |

25 |

0.8 |

| G10-2 |

1.2 |

0.55 |

25 |

| G13-1 |

0.4 |

0.6 |

960 |

0.55 |

25 |

0.8 |

| G13-2 |

1.2 |

0.55 |

25 |

| G15-1 |

0.6 |

0.6 |

960 |

0.55 |

25 |

1 |

| G15-2 |

1.2 |

0.75 |

25 |

| G20-1 |

0.8 |

0.6 |

960 |

0.75 |

25 |

1.5 |

| G20-2 |

0.6 |

1.1 |

25 |

| G25-1 |

2 |

0.6 |

960 |

1.5 |

32 |

2 |

| G25-2 |

1.2 |

2.2 |

32 |

| G30-1 |

5 |

0.6 |

960 |

2.2 |

50 |

2.5 |

| G30-2 |

1.2 |

3 |

50 |

| G35-1 |

8 |

0.6 |

960 |

3 |

65 |

3 |

| G35-2 |

1.2 |

4 |

65 |

| G40-1 |

12 |

0.6 |

960 |

4 |

80 |

3.8 |

| G40-2 |

1.2 |

5.5 |

80 |

| G50-1 |

20 |

0.6 |

960 |

5.5 |

100 |

5 |

| G50-2 |

1.2 |

7.5 |

100 |

| G60-1 |

30 |

0.6 |

960 |

11 |

125 |

6 |

| G60-2 |

1.2 |

15 |

125 |

| G70-1 |

45 |

0.6 |

720 |

11 |

150 |

8 |

| G70-2 |

1.2 |

18.5 |

| G85-1 |

65 |

0.6 |

720 |

15 |

150 |

10 |

| G85-2 |

0.6 |

30 |

| G105-1 |

80 |

0.6 |

720 |

22 |

200 |

10 |

| G135-1 |

100 |

0.6 |

720 |

30 |

200 |

10 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(2).png)

.png)

(2).png)

(2).png)

.jpg)