.jpg)

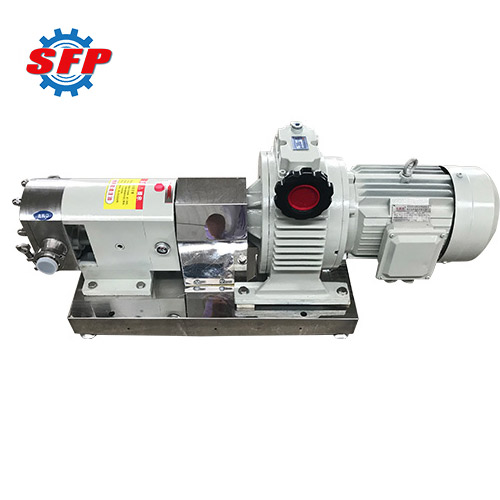

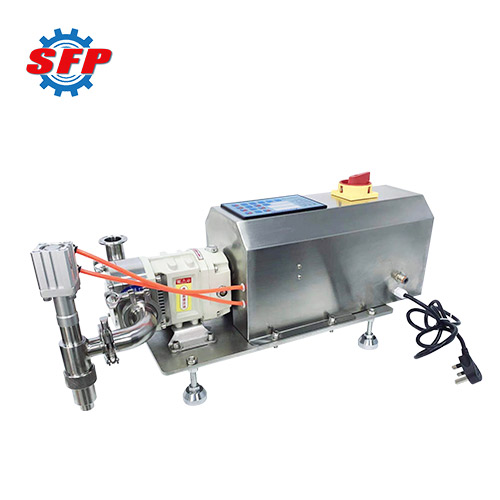

3RP single head lobe filling machine that can fill sanitary fluids and corrosive high viscosity media. Due to its reliable low shear flow characteristics, it is widely used in the food and beverage, daily chemical, pharmaceutical and chemical industries. The unit is manufactured from high quality and durable materials to ensure stable performance under intense operating conditions. Whether it is corrosive chemical liquids or frequent filling cycles, this product operates reliably.

.jpg)

.png)

| Model | Flow | Discharge Pressure (Mpa) |

Rev (rpm) |

Motor Power (kw) |

Inlet/Outlet (mm) |

|

| L/100r | m³/h | |||||

| 3RP-25 | 6 | ≤1.8 | 0-1.0 | 10-400 | 0.75 | 25 |

| 3RP-32 | 9 | ≤2.7 | 1.1 | 32 | ||

| 3RP-40 | 18 | ≤4.3 | 1.5 | 40 | ||

| 3RP-50 | 36 | ≤8.6 | 2.2 | 50 | ||

| 3RP-65 | 60 | ≤14.4 | 4 | 65 | ||

| 3RP-80 | 105 | ≤25.2 | 11 | 80 | ||

| 3RP-100A | 125 | ≤30 | 15 | 100 | ||

| 3RP-100 | 150 | ≤36 | 18.5 | 100 | ||

| 3RP-125 | 250 | ≤60 | 22 | 125 | ||