.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

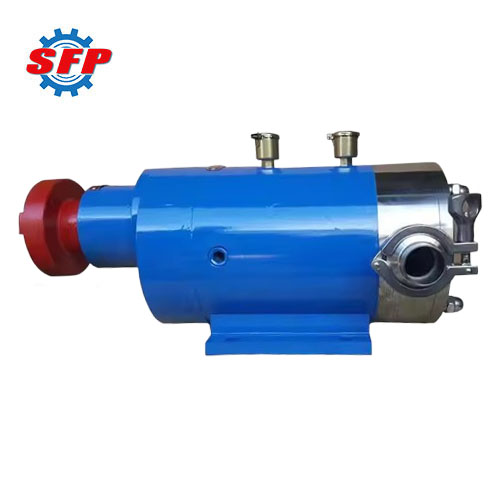

3RP series sanitary lobe pump is a multifunctional two-way positive displacement pump manufactured by our company with German advanced technology. This product can effectively transport high viscosity corrosive media with viscosity up to 30×10⁵cSt, which can be used in daily chemical, building materials, pharmaceutical, petroleum, food and beverage processing industries. At the same time, the internal parts of the pump body in contact with the medium are all made of food-grade stainless steel, which can ensure the safety and non-pollution of the transport medium.

(2).png)

(6).png)

(6).png)

(21).png)

|

Model |

Flow (L/100r) |

Pressure (bar) |

Inlet/Outlet Size |

Rev |

Medium Viscosity |

|

3RP-25 |

6 |

≤10 |

25 |

≤600

|

1-2000000

|

|

3RP-32 |

9 |

≤10 |

32 |

||

|

3RP-40 |

18 |

≤10 |

40 |

||

|

3RP-50 |

36 |

≤10 |

50 |

||

|

3RP-65 |

60 |

≤10 |

65 |

||

|

3RP-80 |

105 |

≤10 |

80 |

||

|

3RP-100A |

125 |

≤10 |

100 |

||

|

3RP-100 |

150 |

≤10 |

100 |

||

| 3RP-125 | 250 | ≤10 | 125 |

.jpg)