.jpg)

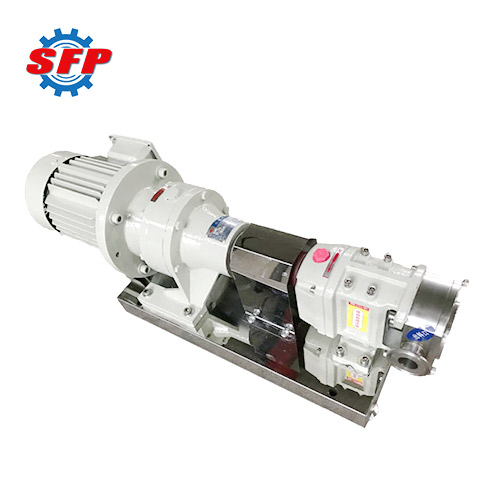

3RP series hygienic lobe pump is a kind of volumetric pump, which is characterized by good self-priming performance, high efficiency and long service life, etc. It can convey suspension, corrosive medium and suspension containing soft solid particles. It can be used to transport suspensions, corrosive media and suspensions containing soft solid particles, the temperature range of the transport medium is -30℃ to 180℃, the viscosity range is 30CST to 100000CST. Moreover, it can be applied to pharmaceutical, chemical, petroleum, food, printing and other industries.

.png)

(2).png)

(18).png)

| Item | Model | Flow | Pressure | Speed | Power | Pipe Size | |

| L/100r | m³/h | Mpa | rpm | kw | DN | ||

| 1 | 3RP-6 | 6 | 1.8 | 0-1.2 | 10-500 | 0.75 | 20/25 |

| 2 | 3RP-9 | 9 | 2.6 | 0-0.6 | 10-500 | 1.1 | 25/32 |

| 3 | 3RP-18 | 18 | 4.3 | 0-0.2 | 10-400 | 1.5 | 32/50 |

| 4 | 3RP-36 | 36 | 8.5 | 0-0.6 | 10-400 | 2.2 | 50/65 |

| 5 | 3RP-60 | 60 | 14.3 | 0-0.6 | 10-400 | 4 | 65/80 |

| 6 | 3RP-105 | 105 | 25 | 0-1.2 | 10-400 | 11 | 80/100 |

| 7 | 3RP-150 | 125/250 | 35 | 0-0.6 | 10-400 | 18.5 | 100/125 |

| 8 | 3RP-250 | 250 | 45 | 0-0.6 | 10-400 | 22 | 125/150 |