.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

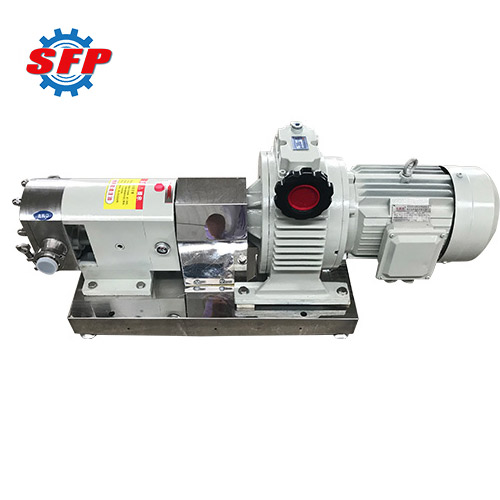

3RP series sanitary lobe pump belongs to one kind of positive displacement pump, which is characterized by reasonable structure, good self-priming performance, high efficiency and low energy consumption. In principle, the pump is not limited by the physical and chemical properties of the medium, and can be used to transport a variety of high-viscosity media with viscosity up to 30×10⁵cSt. Therefore, it can be widely used in daily chemical, petroleum, biopharmaceutical, brewing, food and other processing industries.

(4).png)

.png)

(2).png)

|

Model |

Flow (L/100r) |

Pressure (bar) |

Inlet/Outlet Size |

Rev |

|

3RP-25 |

6 |

≤10 |

25 |

≤600

|

|

3RP-32 |

9 |

≤10 |

32 |

|

|

3RP-40 |

18 |

≤10 |

40 |

|

|

3RP-50 |

36 |

≤10 |

50 |

|

|

3RP-65 |

60 |

≤10 |

65 |

|

|

3RP-80 |

105 |

≤10 |

80 |

|

|

3RP-100A |

125 |

≤10 |

100 |

|

|

3RP-100 |

150 |

≤10 |

100 |

|

| 3RP-125 | 250 | ≤10 | 125 |