.jpg)

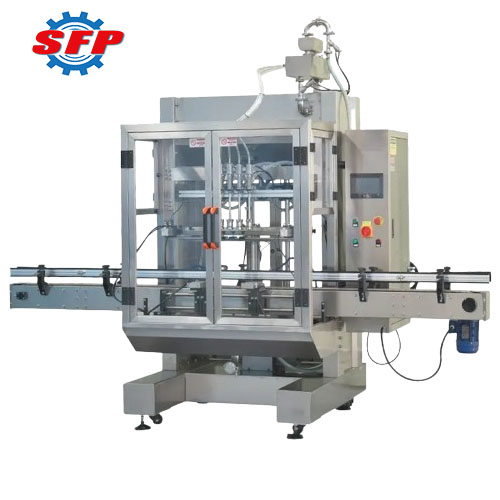

Autoamtic glass bottle filling machine is specially designed for filling different nature of liquids in glass bottle containers, which can be widely used in food, beverage, pharmaceutical, daily chemical and other industries. It is suitable for glass bottles of various specifications and shapes, and can be adapted to different bottle shapes by adjusting the filling head and conveying device. So it can be applied to large, medium as well as small liquid production enterprises.

.png)

.png)

| Filling Nozzels | 2 | 4-6 | 8-10 | 12 |

| Filling Speed | 500 | 600-800 | 1200-2500 | 1800-2500 |

| Filling Volume | 50-500 ml | 500-2500 ml | 2500-5000 ml | 5-30 L |

| Liquid Level Control Accuracy | 1% | |||

| Work Pressure | 0.6-0.8 | |||

| Voltage | 380V/220V/Other voltages can be customized | |||