Summarize:

.jpg)

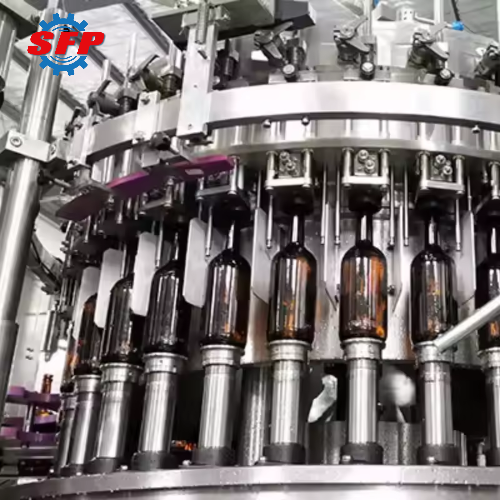

Automatic beer liquid filling machine is suitable for filling all kinds of beer, cold coffee, juice drinks, functional water, and non-carbonated drinks and other liquids. It is a filling machine which integrates rinsing, filling and capping, so the whole process can be automated and easy to operate, thus saving labor cost. The equipment is also characterized by smooth filling, intelligent liquid level control, reliable capping, fast speed, low material loss and frequency conversion speed regulation.

Product Details:

This automatic beer filling machine is mainly used for beverage filling operations, integrating bottle washing, filling and capping. After the beer is filtered through the membrane, it is sent to the rotating beer tank through the pipeline, and then it is put into the bottle through the filling valve, and then it is capped to get the bottled beer. The working efficiency and automation degree of beer filling and capping machine directly affect the daily output of beer. The whole process is automated and the machine can be easily rotated and adjusted to fill various beverages. Using this machine will streamline processes for maximum efficiency and guarantee precision while reducing the need for human intervention.

Application:

1. Beer: Full automatic beer filling machine is specially designed for beer filling, which can efficiently and accurately fill beer into glass bottles, cans and so on.

2. Beverage: It is suitable for filling all kinds of liquid foodstuffs, such as milk, mineral water, edible oil and so on.

3. Sauce products: It can also be used to fill sauces and pasty products, such as ketchup, jam, cream and so on.

Feature:

1. It is also equipped with an automated control system and intelligent monitoring functions, which can monitor various parameters in the production process in real time to ensure the quality and safety of beer.

2. This equipment operates in fully automatic mode, completing bottle transfers between stations as well as cleaning and filling each one without the need for human intervention.

3. The beer filling system machine uses stainless steel as the production material, which reduces wear and is easy to clean.

4. Adoption of control system ensures accurate liquid level and reliable filling.

.jpg)