.jpg)

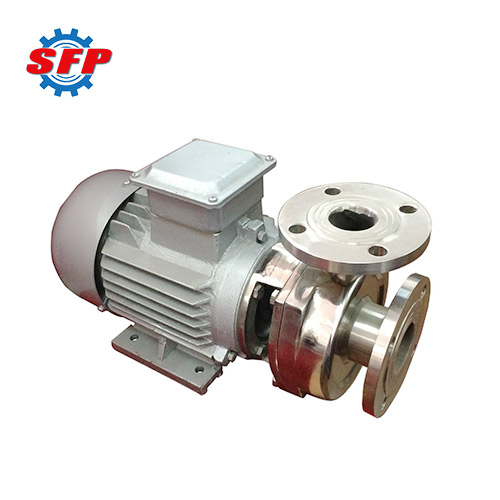

FSB series fluorine alloy centrifugal pump can be used in smelting, dyestuff, pharmacy, chemical industry, petroleum and other industries to transport various corrosive media, such as acids, alkalis, salts, and strong oxidizing agents for a long time. The pump has the benefits of reasonable design, compact structure, reliable performance, convenient operation and maintenance, energy saving and so on.

(1).png)

.png)

| Model | Flow | Head (m) | Size (mm) | Power (Kw) | Speed (r/min) |

NPSHr (m) |

Efficiency (%) |

||||||

| Inlet | Outlet | Shaft | Motor | ||||||||||

| FSB(long legs) | |||||||||||||

| 25FSB-18 | 3 | 18 | 25 | 25 | 0.6 | 1.5 | 2900 | 3.0 | 30 | ||||

| 25FSB-25 | 3.6 | 25 | 25 | 25 | 0.8 | 1.5 | 2900 | 3.0 | 35 | ||||

| 40FSB-15 | 5 | 15 | 40 | 32 | 1.3 | 3 | 2900 | 3.0 | 40 | ||||

| 40FSB-20 | 10 | 20 | 40 | 32 | 1.4 | 3 | 2900 | 3.0 | 42 | ||||

| 40FSB-30 | 10 | 30 | 40 | 32 | 1.6 | 3 | 2900 | 3.0 | 52 | ||||

| 50FSB-20 | 12.5 | 20 | 50 | 32 | 1.7 | 3 | 2900 | 3.5 | 55 | ||||

| 50FSB-25 | 12.5 | 25 | 50 | 32 | 1.86 | 3 | 2900 | 3.5 | 55 | ||||

| 50FSB-30 | 15 | 30 | 50 | 32 | 1.90 | 3 | 2900 | 3.5 | 54 | ||||

| 65FSB-32 | 25 | 32 | 65 | 50 | 4.7 | 5.5 | 2900 | 2.0 | 45 | ||||

| 80FSB-20 | 50 | 20 | 80 | 65 | 4.6 | 5.5 | 2900 | 3.0 | 45 | ||||

| 80FSB-25 | 42 | 25 | 80 | 65 | 5.7 | 7.5 | 2900 | 3.0 | 50 | ||||

| 80FSB-30 | 50 | 30 | 80 | 65 | 6.9 | 7.5 | 2900 | 3.5 | 59 | ||||

| 80FSB-40 | 45 | 40 | 80 | 50 | 10 | 11 | 2900 | 3.5 | 48 | ||||

| 80FSB-50 | 50 | 50 | 80 | 50 | 12.1 | 15 | 2900 | 3.5 | 57 | ||||

| 80FSB-55 | 50 | 55 | 80 | 50 | 13.5 | 18.5 | 2900 | 4.0 | 50 | ||||

| 100FSB-32 | 100 | 32 | 100 | 80 | 11.9 | 15 | 2900 | 3.5 | 68 | ||||

| FSB(short legs) | |||||||||||||

| 40FSB-15(D) | 5 | 15 | 40 | 32 | 0.8 | 3 | 2900 | 3.0 | 40 | ||||

| 40FSB-20(D) | 10 | 20 | 40 | 32 | 1.2 | 3 | 2900 | 3.0 | 42 | ||||

| 40FSB-30(D) | 10 | 30 | 40 | 32 | 1.2 | 3 | 2900 | 3.0 | 52 | ||||

| 50FSB-20(D) | 12.5 | 20 | 50 | 32 | 1.88 | 3 | 2900 | 3.5 | 55 | ||||

| 50 FSB-25(D) | 12.5 | 25 | 50 | 32 | 1.88 | 3 | 2900 | 3.5 | 55 | ||||

| 50FSB-30(D) | 15 | 30 | 50 | 32 | 1.9 | 3 | 2900 | 3.5 | 54 | ||||

| 65FSB-32(D) | 25 | 32 | 65 | 50 | 3.6 | 5.5 | 2900 | 3.5 | 65 | ||||

| 80FSB-25(D) | 42 | 25 | 80 | 65 | 3.8 | 7.5 | 2900 | 3.5 | 67 | ||||

| 80FSB-30(D) | 50 | 30 | 80 | 65 | 6.8 | 7.5 | 2900 | 3.5 | 68 | ||||