.jpg)

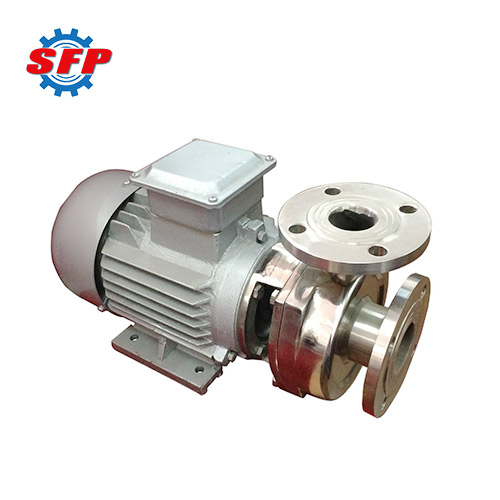

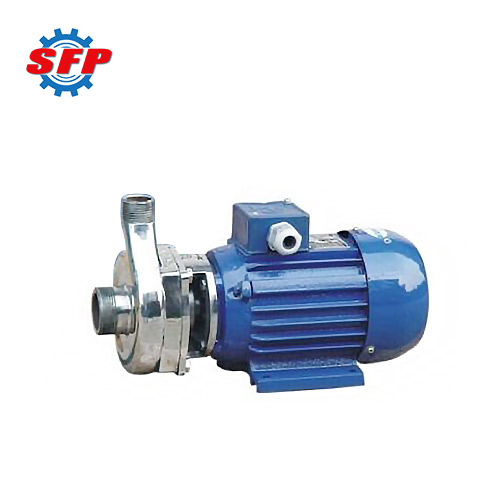

SFB series corrosion resistant centrifugal pump is widely used in food, beverage, pharmaceutical and chemical industries, electroplating, bleaching and dyeing, fine chemical industry and sewage treatment, etc. They can transport liquids containing fine soft particles or fibrous materials, corrosive or with sanitary requirements. In order to ensure that the pump has no leakage during operation, our pump adopts cantilever technology mechanical seal with good corrosion resistance.

.png)

| Model (Three-phase/380V/50Hz) |

Model (Single-phase/380V/50Hz) |

Power (kW) |

Inlet (mm) |

Outlet (mm) |

Efficiency (%) |

H: Head(m) Q: Flow(m³/h) |

NPSH(m) | |||||||||

| 25SFB-8 | 25SFB-8D | 0.25 | 25 | 20 | 43 | H | 11 | 10 | 8 | 6 | 4 | 3 | 4.5 | |||

| Q | 0.8 | 2.5 | 4 | 5.2 | 6.8 | 7.5 | ||||||||||

| 40SFB-13 | 40SFB-13D | 0.55 | 40 | 25 | 45 | H | 15 | 14 | 13 | 12 | 10 | 8 | 6 | 5 | 3.5 | |

| Q | 3.5 | 5 | 6 | 7.5 | 9.5 | 11 | 12.5 | 13 | ||||||||

| 50SFB-18 | 50SFB-18D | 1.5 | 50 | 40 | 52 | H | 22 | 21 | 20 | 18 | 16 | 14 | 12 | 10 | 3.5 | |

| Q | 3 | 5.5 | 9 | 13 | 16 | 18 | 20 | 21 | ||||||||

| 50SFB-22 | 50SFB-22D | 2.2 | 50 | 40 | 55 | H | 27 | 26 | 24 | 22 | 20 | 18 | 16 | 14 | 12 | 3.5 |

| Q | 7 | 10.5 | 16 | 19 | 22 | 23.8 | 26 | 27 | 28.5 | |||||||

| 50SFB-25 | 3 | 50 | 40 | 56 | H | 30 | 28 | 26 | 25 | 24 | 22 | 20 | 18 | 16 | 3.5 | |

| Q | 12.5 | 18.5 | 22 | 23 | 24.5 | 26 | 27.5 | 29.5 | 31 | |||||||