.png)

.png)

.png)

.jpg)

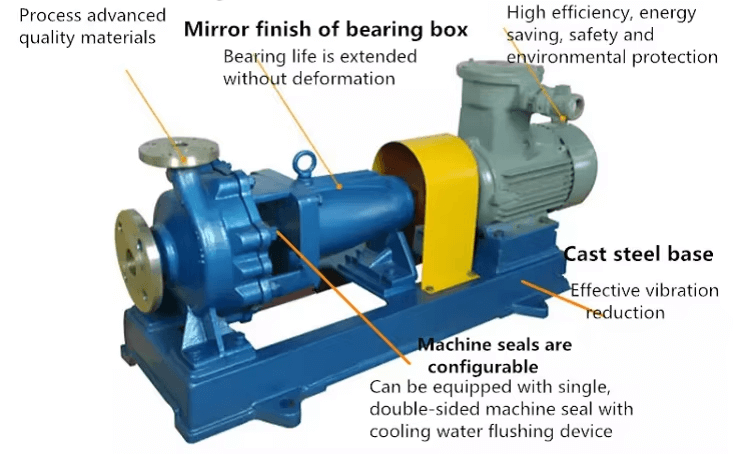

IH series chemical centrifugal pumps are horizontal single-stage single-suction cantilevered centrifugal pumps, which can meet the corrosive viscosity requirements of chemical process liquids. Its mark, rated performance point and external dimensions adopt international standard ISO2858-1975(E), which is an energy-saving updated product of the ministry of machinery industry to replace F-type corrosive centrifugal pump. It can meet the corrosive viscosity requirements of chemical process liquids. The temperature of the pump's conveying medium is generally ≤80℃, and the temperature of the conveying medium can be higher with appropriate cooling measures if necessary. Therefore, it is widely used in industry, agriculture and urban, drainage, fire water supply and other fields.

| Model | Speed (r/min) |

Flow (m³/h) |

Flow (L/S) |

Head (m) |

Power | ||

| Medium Density | |||||||

| 1.0 | 1.35 | 1.85 | |||||

| IH50-32-125 | 2900 | 12.5 | 3.47 | 20 | 2.2 | 6.0 | 4.0 |

| 1450 | 6.3 | 1.74 | 5.0 | 0.55 | 0.55 | 0.55 | |

| IH50-32-160 | 2900 | 12.5 | 3.47 | 32 | 3.0 | 4.0 | 5.5 |

| 1450 | 6.3 | 1.74 | 8.0 | 0.55 | 0.75 | 1.1 | |

| IH50-32-200 | 2900 | 12.5 | 3.47 | 50 | 5.5 | 7.5 | 11 |

| 1450 | 6.3 | 1.74 | 12.5 | 1.1 | 1.1 | 1.5 | |

| IH50-32-250 | 2900 | 12.5 | 3.47 | 80 | 11 | 15 | 18.5 |

| 1450 | 6.3 | 1.74 | 20 | 2.2 | 2.2 | 3.0 | |

| IH65-50-125 | 2900 | 25 | 1.53 | 2.0 | 3.0 | 4.0 | 5.5 |

| 1450 | 12.5 | 6.94 | 5.0 | 0.55 | 0.55 | 0.75 | |

| IH65-50-160 | 2900 | 25 | 2.78 | 32 | 5.5 | 7.5 | 11 |

| 1450 | 12.5 | 6.94 | 8.0 | 0.75 | 1.1 | 1.5 | |

| IH65-40-200 | 2900 | 25 | 2.92 | 50 | 11 | 11 | 15 |

| 1450 | 12.5 | 6.94 | 12.5 | 1.5 | 2.2 | 2.2 | |

| IH65-40-250 | 2900 | 25 | 2.92 | 80 | 15 | 3.0 | 30 |

| 1450 | 12.5 | 6.94 | 20 | 2.2 | 37 | 4.0 | |

| IH65-40-315 | 2900 | 25 | 3.06 | 125 | 30 | 5.5 | 55 |

| 1450 | 12.5 | 6.94 | 32.0 | 5.5 | 5.5 | 7.5 | |

| IH80-65-125 | 2900 | 50 | 13.9 | 20 | 5.5 | 7.5 | 11 |

| 1450 | 25 | 6.94 | 5.0 | 0.75 | 1.1 | 1.5 | |

| IH80-65-160 | 2900 | 50 | 13.9 | 32 | 11 | 11 | 15 |

| 1450 | 25 | 6.94 | 8.0 | 1.5 | 1.5 | 2.2 | |

| IH80-50-200 | 2900 | 50 | 13.9 | 50 | 15 | 18.5 | 30 |

| 1450 | 25 | 6.94 | 12.5 | 1.1 | 1.5 | 2.2 | |

| IH80-50-250 | 2900 | 50 | 13.9 | 80 | 30 | 37 | 45 |

| 1450 | 25 | 6.94 | 20 | 4.0 | 5.5 | 7.5 | |

| IH80-50-315 | 2900 | 50 | 13.9 | 125 | 45 | 55 | 75 |

| 1450 | 25 | 6.94 | 32 | 7.5 | 7.5 | 11 | |

| IH100-80-125 | 2900 | 100 | 27.8 | 20 | 11 | 15 | 18.5 |

| 1450 | 50 | 13.9 | 5.0 | 1.5 | 2.2 | 3.0 | |

| IH100-80-160 | 2900 | 100 | 27.8 | 32 | 15 | 22 | 30 |

| 1450 | 50 | 13.9 | 8.0 | 2.2 | 3.0 | 4.0 | |

| IH100-65-200 | 2900 | 100 | 27.8 | 50 | 30 | 37 | 45 |

| 1450 | 50 | 13.9 | 12.5 | 3.0 | 4.0 | 5.5 | |

| IH100-65-250 | 2900 | 100 | 27.8 | 80 | 45 | 55 | 75 |

| 1450 | 50 | 13.9 | 20 | 5.5 | 7.5 | 11 | |

| IH100-65-315 | 2900 | 100 | 55.6 | 125 | 75 | 90 | 132 |

| 1450 | 50 | 27.8 | 32 | 11 | 15 | 18.5 | |

| IH125-100-200 | 2900 | 200 | 55.6 | 50 | 45 | 55 | 90 |

| 1450 | 100 | 27.8 | 12.5 | 7.5 | 11 | 15 | |

| IH125-100-250 | 2900 | 200 | 55.6 | 80 | 11 | 110 | 132 |

| 1450 | 100 | 27.8 | 20 | 132 | 15 | 18.5 | |

| IH125-100-315 | 2900 | 200 | 55.6 | 125 | 18.5 | 160 | 220 |

| 1450 | 100 | 27.8 | 32 | 18.5 | 22 | 30 | |

| IH125-100-400 | 1450 | 100 | 27.8 | 50 | 18.5 | 30 | 37 |

| IH50-125-250 | 1450 | 200 | 55.6 | 20 | 30 | 30 | 37 |

| IH50-125-315 | 1450 | 200 | 55.6 | 32 | 30 | 37 | 55 |

| IH50-125-400 | 1450 | 200 | 55.6 | 50 | 55 | 75 | 90 |

| IH200-150-250 | 1450 | 400 | 111.1 | 20 | 37 | 55 | 75 |

| IH200-150-315 | 1450 | 400 | 111 | 32 | 55 | 75 | 110 |

| IH200-150-400 | 1450 | 400 | 111 | 50 | 90 | 132 | 160 |