Summarize:

.jpg)

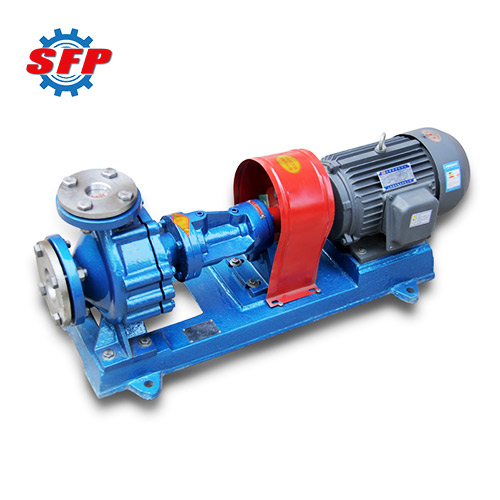

FSB series fluorine plastic centrifugal pump can be used for long-term transportation of various acidic, oxidizing, corrosive and other media with physical properties similar to water. The equipment integrates the advantages of various fluoroplastics, featuring strong corrosion resistance, high mechanical strength and non-toxic decomposition. Therefore, it is commonly used for electrolyte conveying in the process of non-ferrous metal smelting, wastewater treatment, acid washing and automobile manufacturing paint spraying process. Meanwhile, the pump body of the pump is lined with fluoroplastic in a metal casing, which has high mechanical strength and can withstand certain working pressure and load.

Product Details:

Under the action of centrifugal force, the liquid will be thrown from the center of the impeller of the pump to the outer edge of the impeller, thus forming a low-pressure area in the center of the impeller. The liquid is sucked into the pump through the suction line under the action of external atmospheric pressure. After the liquid enters into the pump casing at a high speed, due to the gradual expansion of the flow channel of the pump casing, the flow rate of the liquid is gradually reduced, the pressure of the liquid is further increased, and finally the liquid is transported to the required place through the press-out pipeline.

.png)

Application:

FSB series fluorine alloy centrifugal pump can convey various concentrations of sulfuric acid, hydrochloric acid, acetic acid, hydrofluoric acid, nitric acid, aqua regia, strong bases, strong oxidizing agents, organic solvents, reducing agents and other acidic, oxidizing and strong corrosive media under harsh conditions. Widely used in chemical industry, acid production, alkali production, smelting, rare earths, pesticides, dyes, pharmaceuticals, papermaking, electroplating, electrolysis, pickling, radio, chemical foils, scientific research institutes, national defense industry and other industries.

Feature:

1. FSB series centrifugal pump adopts fluoroplastic alloy as the material of overflow parts, which is capable of conveying strong corrosive media with various concentrations of sulfuric acid, hydrochloric acid, acetic acid, nitric acid, strong alkali, organic solvents and other harsh conditions.

2. The shaft seal adopts external bellows mechanical seal, the static ring is made of 99% alumina ceramic or silicon nitride, and the dynamic ring is made of tetrafluoro filler material, which is reliable and can effectively prevent the leakage of medium.

3. Its has the features of smooth running, low vibration, low noise, can provide users with a quiet working environment. Smooth flow path, high efficiency, can effectively save energy and reduce operating costs.

Performance Data:

| Model |

Flow

(m³/h) |

Lift

(m) |

Motor Power

(kw) |

Speed

(r/min) |

NPSH

(m) |

Efficiency

(%) |

| 25FSB-25(D) |

3 |

25 |

1.5 |

2900 |

3 |

20 |

| 40FSB-15(D) |

5 |

15 |

1.5 |

2900 |

3 |

40 |

| 40FSB-20(D) |

10 |

20 |

2.2 |

2900 |

3 |

42 |

| 40FSB-30(D) |

10 |

30 |

3 |

2900 |

3 |

52 |

| 50FSB-20(D) |

12.5 |

20 |

3 |

2900 |

3.5 |

55 |

| 50FSB-25(D) |

12.5 |

25 |

3 |

2900 |

3.5 |

55 |

| 50FSB-30(D) |

15 |

30 |

4 |

2900 |

3.5 |

54 |

| 65FSB-32(D) |

25 |

32 |

5.5 |

2900 |

3.5 |

65 |

| 80FSB-20(D) |

50 |

20 |

5.5 |

2900 |

3 |

55 |

| 80FSB-25(D) |

50 |

25 |

5.5 |

2900 |

3.5 |

67 |

| 80FSB-32(D) |

50 |

32 |

7.5 |

2900 |

3.5 |

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)