Summarize:

.jpg)

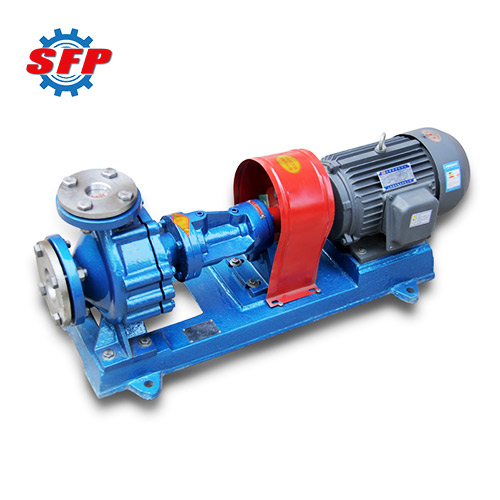

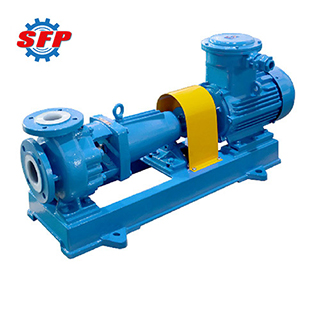

TSB series chemical centrifugal pumps are a series of single-stage, single-suction cantilevered centrifugal pumps. It is a standard chemical pump upgraded on the basis of IH pump, designed and produced according to ISO2858 standard. This pumps can meet the requirements of metallurgy, chemical, petroleum, power station, environmental protection, metallurgy and other industries, and are widely used in the process of decolorization of oil and grease.

Product Details:

TSB series chemical centrifugal pumps are designed and manufactured in accordance with ISO2858 standards, utilizing durable materials and strict production standards, and are capable of stable operation for a long time under harsh working environments. This equipment can transport grease from one place to another by centrifugal force, and at the same time realize the function of decoloration in the process.

Application:

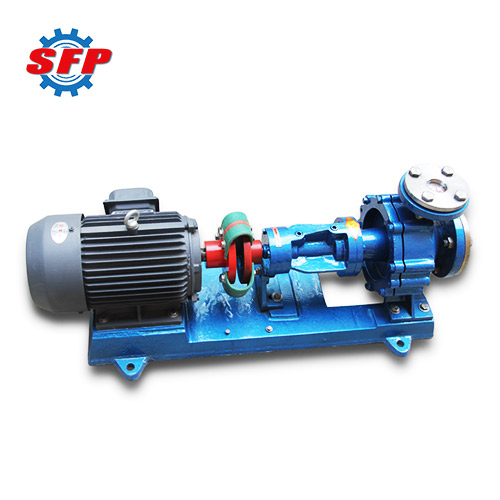

TSB series grease centrifugal pump is mainly used in petroleum, chemical, synthetic fiber, chemical fertilizer, power station, metallurgy, food and medicine and other industrial sectors to transport clean or particle-containing liquids, low or high temperature liquids, neutral or corrosive liquids, and the temperature of the conveying medium is -45°C ~200°C. High temperature type and slurry type medium temperature -60°C~+360°C to transport corrosive slurry with particles at high temperature and normal temperature, or corrosive liquid similar to water. It is suitable for chemical, petroleum, metallurgy, pharmaceutical, brewing, power generation, food, environmental protection, etc. and harsh environments.

Feature:

1. The pump adopts the international standard structure design, and the impeller is a conical open structure, which is suitable for conveying liquids with high particle concentration and various suspensions.

2. Horizontal radial split, rear door structure, no need to remove pipeline and motor when disassembling the pump.

3. It has the characteristics of high lift, small flow, low cavitation allowance, etc.

4. The shaft seal of the pump adopts dynamic seal and mechanical seal, which is safe and reliable.

5. Wearing parts of the impeller end cover can be replaced, maintenance is simple and quick, and the production cost is reduced.

6. The rotor of the pump can be compensated axially to increase the service life.

Parameter Data:

| Model |

Flow(m³/h) |

Head(m) |

NPSHR(m) |

Speed(r/min) |

Motor Power(Kw) |

Efficiency(%) |

| TSB40-25-180 |

6 |

40 |

2 |

2900 |

4 |

49 |

| TSB50-32-200 |

12.5 |

50 |

2 |

2900 |

5.5 |

48 |

| TSB65-40-250 |

25 |

80 |

2 |

2900 |

15 |

53 |

| TSB80-50-250 |

50 |

80 |

2.6 |

2900 |

30 |

58 |

| TSB80-50-315 |

50 |

125 |

2 |

2900 |

45 |

52 |

| TSB100-65-200 |

100 |

50 |

3.9 |

2900 |

22 |

72 |

.jpg)

.jpg)