Summarize:

.jpg)

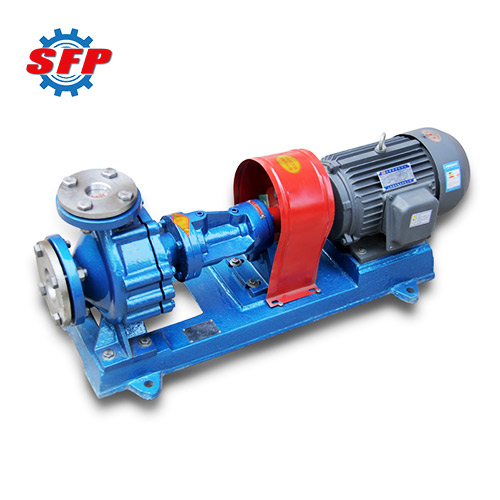

FSB series fluolorplastic centrifugal pumps are suitable for long-term handling of media including hydrochloric acid, sulfuric acid, alkali solutions, strong oxidizing agents, and reducing agents at any concentration. The equipment features exceptional corrosion resistance, high mechanical strength, anti-aging properties, and non-toxic decomposition characteristics, making it a reliable choice for chemical processing, pesticide production, non-ferrous metallurgy, wastewater treatment, and electronics industries.

Product Details:

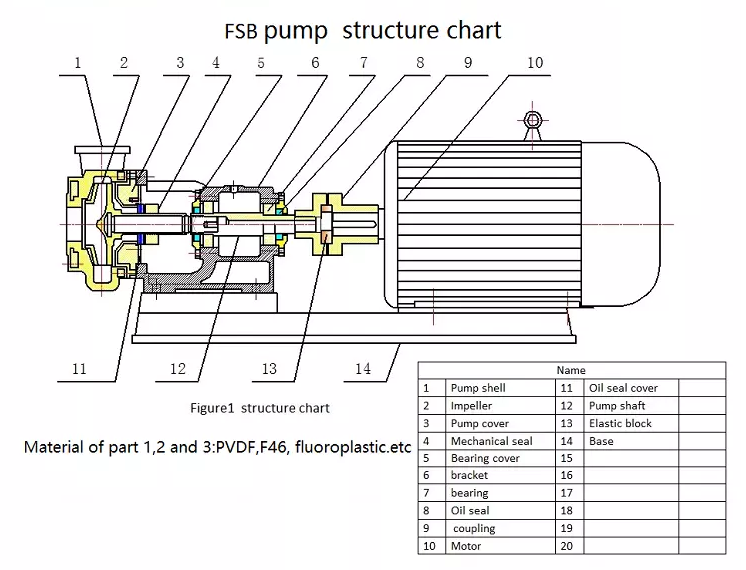

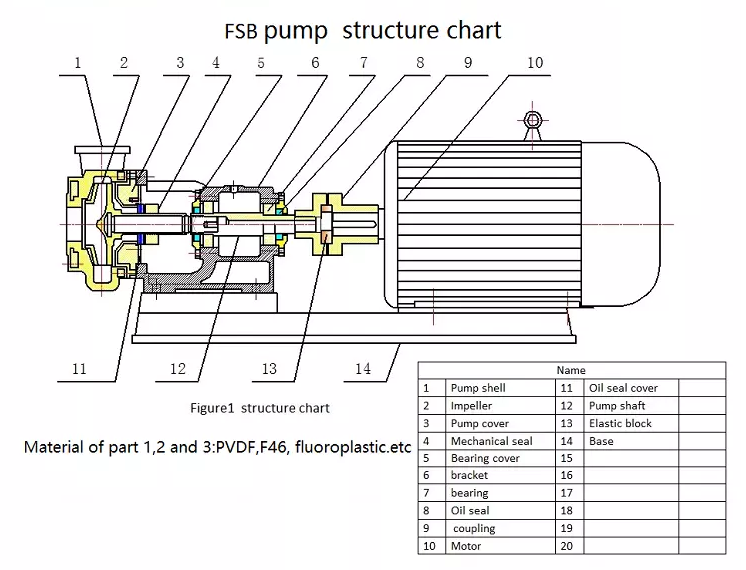

FSB series chemical centrifugal pumps are constructed from fully fluorinated plastic alloys and equipped with advanced externally mounted PTFE bellows mechanical seals. Upon pump startup, centrifugal force propels the liquid outward from the impeller's center toward its periphery, creating a low-pressure zone at the impeller core. As atmospheric pressure draws liquid into the pump, the high-velocity fluid enters the pump casing. It then decelerates as the flow passage gradually widens, resulting in a corresponding decrease in pressure.

Application:

FSB series fluorine plastic centrifugal pumps are capable of long-term conveying of highly corrosive media including sulfuric acid, hydrochloric acid, acetic acid, hydrofluoric acid, nitric acid, strong alkalis, strong oxidizing agents, organic solvents, and reducing agents at various concentrations. They are applicable for industries including chemical processing, acid plants, alkali plants, pesticides, pharmaceuticals, papermaking, electroplating, acid washing, radio equipment, electrolytic foil manufacturing, research institutes, and defense industries.

Feature:

1. This series of pumps utilizes fluoroplastic alloy as the material for overflow components, offering exceptional corrosion resistance, reliable performance, and anti-aging properties, making them an ideal choice for highly corrosive operating conditions.

2. The pump employs an external bellows mechanical seal for shaft sealing, featuring a stationary ring made of 99% alumina ceramic or silicon nitride, and a rotating ring with PTFE packing.

3. The corrosion-resistant and wear-resistant sealing design incorporates multi-layer protection to extend the mechanical seal's service life.

Performance Data:

| Model |

Flow

(m³/h) |

Lift

(m) |

Motor Power

(kw) |

Speed

(r/min) |

NPSH

(m) |

Efficiency

(%) |

| 25FSB-25(D) |

3 |

25 |

1.5 |

2900 |

3 |

20 |

| 40FSB-15(D) |

5 |

15 |

1.5 |

2900 |

3 |

40 |

| 40FSB-20(D) |

10 |

20 |

2.2 |

2900 |

3 |

42 |

| 40FSB-30(D) |

10 |

30 |

3 |

2900 |

3 |

52 |

| 50FSB-20(D) |

12.5 |

20 |

3 |

2900 |

3.5 |

55 |

| 50FSB-25(D) |

12.5 |

25 |

3 |

2900 |

3.5 |

55 |

| 50FSB-30(D) |

15 |

30 |

4 |

2900 |

3.5 |

54 |

| 65FSB-32(D) |

25 |

32 |

5.5 |

2900 |

3.5 |

65 |

| 80FSB-20(D) |

50 |

20 |

5.5 |

2900 |

3 |

55 |

| 80FSB-25(D) |

50 |

25 |

5.5 |

2900 |

3.5 |

67 |

| 80FSB-32(D) |

50 |

32 |

7.5 |

2900 |

3.5 |

.jpg)

.png)