Summarize:

.jpg)

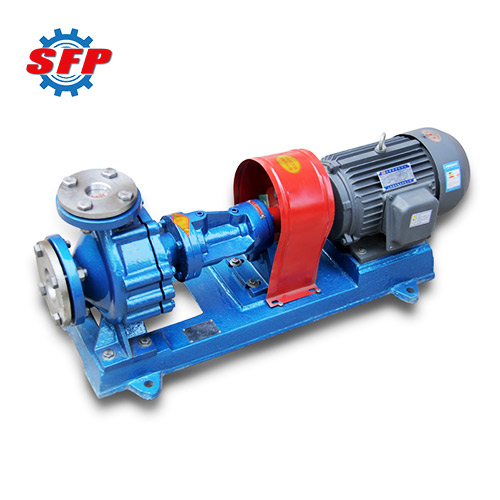

FSB centrifugal chemical pump belongs a kind of fluoroplastic alloy centrifugal pump, featuring exceptional corrosion resistance, high mechanical strength, non-aging properties, non-toxic decomposition, and reliable performance. This pump is suitable for conveying media such as hydrochloric acid, sulfuric acid, alkali solutions, strong oxidizing agents, and reducing agents at any concentration. It finds application in various industries including chemical processing, pharmaceutical manufacturing, metallurgy, electrolysis, electroplating, papermaking, and wastewater treatment.

Product Details:

FSB series fluoroplastic centrifugal pump is manufactured from fluoroplastic alloys with outstanding corrosion resistance, capable of handling highly corrosive media across all concentrations. This pump feature multi-layered PTFE bellows mechanical seals, its covers, impellers, and shaft sleeves employ a metal core lined with fluoroplastic, ensuring true resistance to aging, elimination of toxic decomposition, and complete prevesntion of leakage.

.jpg)

Application:

FSB series horizontal centrifugal pumps are suitable for conveying corrosive liquids of various concentrations, such as nitric acid, hydrochloric acid, sulfuric acid, hydrofluoric acid, strong alkalis, organic solvents, and strong oxidizing agents. They can be applied in industries including chemical processing, petroleum, pharmaceuticals, acid washing, dyeing, electroplating, smelting, papermaking, and electrolysis.

Feature:

1. This series of pumps utilizes fluoroplastic alloy as the material for overflow components, offering exceptional corrosion resistance, reliable performance, and resistance to aging. It makes them an ideal choice for highly corrosive operating conditions.

2. The shaft seal employs an external bellows mechanical seal, with the stationary ring made from 99% alumina ceramic or silicon nitride. This dynamic seal ensures reliable performance, effectively preventing medium leakage to protect the machinery.

3. Featuring smooth operation, low vibration, and minimal noise, these pumps provide users with a quiet working environment.

Performance Data:

| Model |

Flow

(m³/h) |

Lift

(m) |

Motor Power

(kw) |

Speed

(r/min) |

NPSH

(m) |

Efficiency

(%) |

| 25FSB-25(D) |

3 |

25 |

1.5 |

2900 |

3 |

20 |

| 40FSB-15(D) |

5 |

15 |

1.5 |

2900 |

3 |

40 |

| 40FSB-20(D) |

10 |

20 |

2.2 |

2900 |

3 |

42 |

| 40FSB-30(D) |

10 |

30 |

3 |

2900 |

3 |

52 |

| 50FSB-20(D) |

12.5 |

20 |

3 |

2900 |

3.5 |

55 |

| 50FSB-25(D) |

12.5 |

25 |

3 |

2900 |

3.5 |

55 |

| 50FSB-30(D) |

15 |

30 |

4 |

2900 |

3.5 |

54 |

| 65FSB-32(D) |

25 |

32 |

5.5 |

2900 |

3.5 |

65 |

| 80FSB-20(D) |

50 |

20 |

5.5 |

2900 |

3 |

55 |

| 80FSB-25(D) |

50 |

25 |

5.5 |

2900 |

3.5 |

67 |

| 80FSB-32(D) |

50 |

32 |

7.5 |

2900 |

3.5 |

.jpg)

.jpg)

.png)