Summarize:

.jpg)

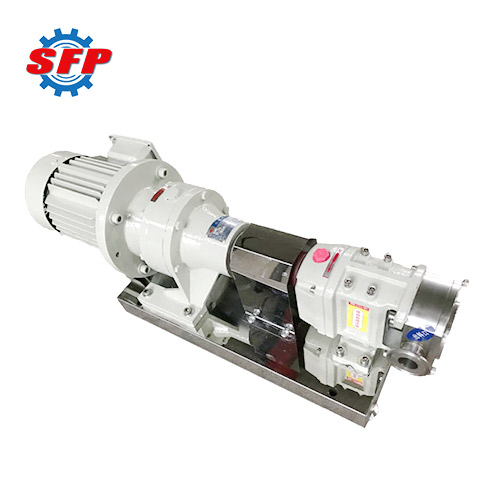

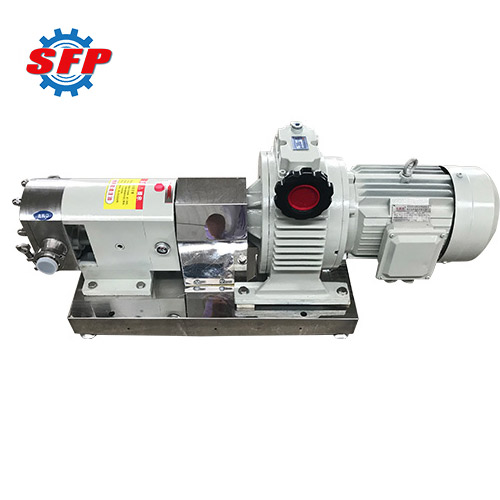

3RP stainless steel rotor pump features all components constructed from wear-resistant, corrosion-resistant stainless steel, ensuring the transported medium retains its original properties and state throughout the process. Consequently, it is particularly suitable for handling corrosive, high-viscosity fluids and those requiring strict compliance with sanitary standards in industries such as beverages, food, cosmetics, pharmaceuticals, chemicals, and petroleum. This equipment offers broad transfer capabilities, low shear, low pulsation, and strong self-priming, enabling efficient, contamination-free transfer of high-viscosity, particulate-laden, and corrosive media.

Product Details:

3RP series high viscosity lobe pump primarily consists of a rotor, shaft seal, gearbox, and a pair of synchronously meshed drive gears. When the synchronous gears drive the cam rotor to rotate in opposite directions, multiple dynamic sealed chambers form between the rotor and pump cavity. The volume of the inlet-side chamber gradually increases, thereby drawing in high-viscosity or particulate-laden media. As the rotor continues rotating, each chamber gradually closes and moves toward the outlet, achieving smooth, pulsation-free material transfer to complete the pumping process.

Application:

1. Chemical Industry: For processing resins, adhesives, coatings, pigments, asphalt, and lubricants.

2. Pharmaceutical Industry: It is suitable for conveying ointments, nutrient solutions, vaccines, and medicinal oils.

3. Petrochemical Industry: For handling palm oil, fatty acids, oleic acid, stearic acid, waste oil, oil sludge, polymers, and catalysts.

4. Household Chemicals: Avaiable for transporting dishwashing liquid, laundry detergent, shower gel, toothpaste, soap base, skin cream, and fragrances.

5. Food Industry: Suitable for transporting yogurt, cream, ice cream, cheese blocks, jam, yeast, ketchup, edible oil, whey, malt extract, syrup, and chocolate.

Feature:

1. The rotors maintain a specific clearance with zero friction coefficient, ensuring extended pump service life.

2. This pump supports multi-head delivery, simultaneously meeting the conveying demands of multiple production lines.

3. The curve design enables low-shear conveying, preserving the original structure and properties of the conveyed medium.

4. Possesses robust conveying capability, handling particles up to 25mm in diameter while maintaining stable operation even with solid content ≤70%.

5. All fluid-contacting components can be manufactured from 316L/304 stainless steel and support CIP/SIP online cleaning, effectively reducing cleaning and maintenance time and costs.

Performance Data:

| Model |

Flow |

Discharge Pressure

(Mpa) |

Rev

(rpm) |

Motor Power

(kw) |

Inlet/Outlet

(mm) |

| L/100r |

m³/h |

| 3RP-25 |

6 |

≤1.8 |

0-1.0 |

10-400 |

0.75 |

25 |

| 3RP-32 |

9 |

≤2.7 |

1.1 |

32 |

| 3RP-40 |

18 |

≤4.3 |

1.5 |

40 |

| 3RP-50 |

36 |

≤8.6 |

2.2 |

50 |

| 3RP-65 |

60 |

≤14.4 |

4 |

65 |

| 3RP-80 |

105 |

≤25.2 |

11 |

80 |

| 3RP-100A |

125 |

≤30 |

15 |

100 |

| 3RP-100 |

150 |

≤36 |

18.5 |

100 |

| 3RP-125 |

250 |

≤60 |

22 |

125 |

.png)

.png)

.png)

.jpg)