Summarize:

.jpg)

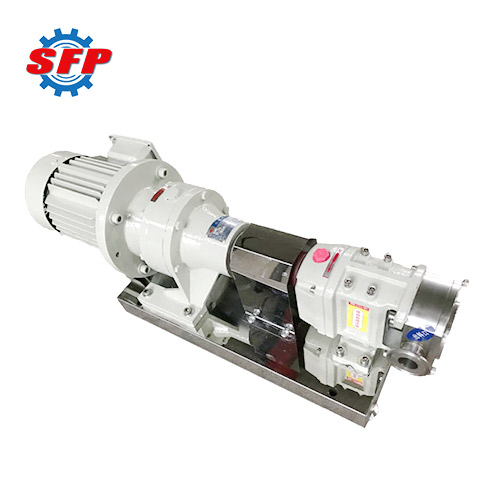

3RP food-grade rotary vane pump is specifically designed for handling medium-to-high viscosity, particulate-laden, and corrosive media. It finds primary application in the beverage, brewing, food, biopharmaceutical, personal care, petroleum, and chemical industries. All material-contacting components are constructed from sanitary-grade stainless steel, ensuring product hygiene while meeting food processing standards. Additionally, the equipment's positive displacement principle minimizes shear force on materials, making it particularly suitable for conveying shear-sensitive media such as yogurt, emulsions, and high-molecular-weight polymers to preserve their original properties.

Product Details:

3RP series lobe pump primarily consists of a rotor, shaft seal, gearbox, and a pair of meshing drive gears. It achieves medium transfer by driving the rotor. The main shaft and auxiliary shaft drive the rotor to rotate synchronously in opposite directions via a gear transmission mechanism, thereby creating volumetric changes within the pump chamber. This design enables higher vacuum levels and discharge pressures, ensuring stable and efficient transfer of highly corrosive and high-viscosity media.

.png)

Application:

1. Food industry: Suitable for conveying yogurt, cream, jam, syrup, beer, yeast, condiments, and edible oils.

2. Daily chemical industry: Commonly used for conveying facial cleansers, toothpaste, perfumes, detergents, cosmetics, and glycerin.

3. Pharmaceutical industry: Enables smooth transportation of syrups, vaccines, nutrient solutions, royal jelly, and various biological products.

4. Chemical Industry: This pump meets the requirements for industrial transfer of resins, coatings, dyes, latex, lubricants, and emulsified asphalt.

Feature:

1. Its rotor features a zero-friction coefficient clearance design, significantly extending the pump's service life.

2. The built-in variable frequency drive enables flexible flow adjustment, making it a versatile metering pump.

3. This equipment delivers outstanding pumping performance when conveying high-viscosity media or handling gas-liquid-solid three-phase mixtures.

4. Inlet and outlet ports can be customized with flange or threaded connections based on specific application requirements, allowing flexible interfacing through flange or threaded ports.

Performance Data:

| Model |

Flow |

Discharge Pressure

(Mpa) |

Rev

(rpm) |

Motor Power

(kw) |

Inlet/Outlet

(mm) |

| L/100r |

m³/h |

| 3RP-25 |

6 |

≤1.8 |

0-1.0 |

10-400 |

0.75 |

25 |

| 3RP-32 |

9 |

≤2.7 |

1.1 |

32 |

| 3RP-40 |

18 |

≤4.3 |

1.5 |

40 |

| 3RP-50 |

36 |

≤8.6 |

2.2 |

50 |

| 3RP-65 |

60 |

≤14.4 |

4 |

65 |

| 3RP-80 |

105 |

≤25.2 |

11 |

80 |

| 3RP-100A |

125 |

≤30 |

15 |

100 |

| 3RP-100 |

150 |

≤36 |

18.5 |

100 |

| 3RP-125 |

250 |

≤60 |

22 |

125 |

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)