Summarize:

.jpg)

ZYB series gear pumps are capable of conveying liquid media containing non-metallic impurities, such as diesel fuel, heavy oil, coal tar, and engine oil. They serve as the core support for applications requiring stable pressure and long-term continuous operation in burners, asphalt mixing plants, and heavy-duty lubrication systems. Featuring self-sealing lubrication and automatic pressure regulation, these pumps automatically restore pressure after wear without requiring disassembly, resulting in a longer service life compared to conventional gear pumps.

Product Details:

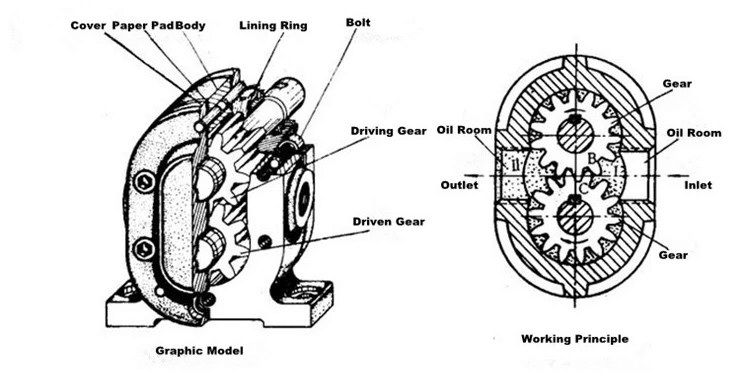

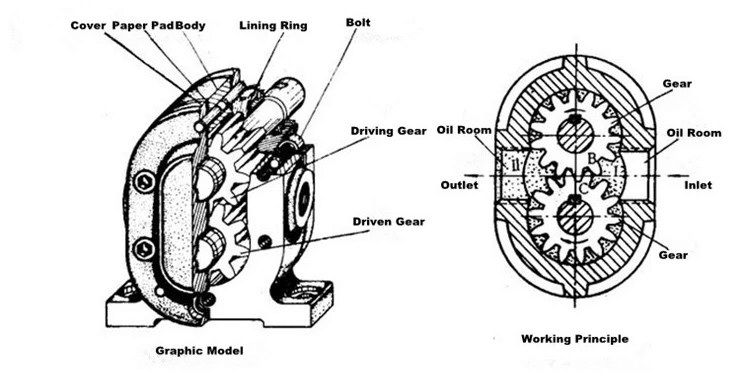

ZYB series oil gear pump consists of components such as the pump body, pump cover, gears, shaft seal, and stuffing box, with two identical sets of drive gears and driven gears housed within the pump body. When the drive gears of a gear pump rotate from an electric motor, the gears mesh, gradually decreasing the volume between the teeth, this action forces the oil to be squeezed out to the outlet.

Application:

ZYB series oil transfer pumps are applicable for conveying non-metallic impurity liquid media with temperatures below 260°C and viscosities not exceeding 150 mm²/s, such as kerosene, heavy oil, residual oil, and fuel oil. These pumps find extensive application in petroleum, chemical, grain and oil, building materials, daily chemicals, road construction, power generation, and asphalt mixing plants.

Feature:

1. Its external design, mounting dimensions, and flanges are fully compatible with the KCB series standard gear pumps, ensuring high interchangeability.

2. The pump gears endure lower torque during operation, thereby reducing bearing load and wear while effectively enhancing pump efficiency.

3. With hydraulic balancing technology, it maintains high efficiency, low noise, and minimal pulsation even under high-pressure conditions.

Performance Data:

| Type |

Inlet and Outlet |

Flow |

Pressure |

Speed |

Suction Height |

Power |

| mm |

m³/h |

L/min |

MPa |

r/min |

m |

kw |

| ZYB4/0.6 |

25 |

4 |

66 |

0.6 |

960 |

5 |

1.5 |

| ZYB7/0.6 |

40 |

7 |

116 |

0.6 |

960 |

5 |

3 |

| ZYB13/0.6 |

50 |

13 |

216 |

0.6 |

960 |

5 |

4 |

| ZYB13/1.0 |

50 |

13 |

216 |

1.0 |

960 |

5 |

5.5 |

| ZYB18/0.6 |

70 |

18 |

300 |

0.6 |

960 |

5 |

7.5 |

| ZYB18/1.0 |

70 |

18 |

300 |

1.0 |

960 |

5 |

11 |

| ZYB30/0.6 |

80 |

30 |

500 |

0.6 |

960 |

5 |

7.5 |

| ZYB38/0.4 |

100 |

38 |

633 |

0.4 |

960 |

5 |

15 |

| ZYB45/0.6 |

100 |

45 |

750 |

0.4 |

960 |

5 |

18.5 |

| ZYB60/0.6 |

100 |

60 |

1000 |

0.4 |

960 |

5 |

22 |

.png)

.jpg)

.png)