Summarize:

.jpg)

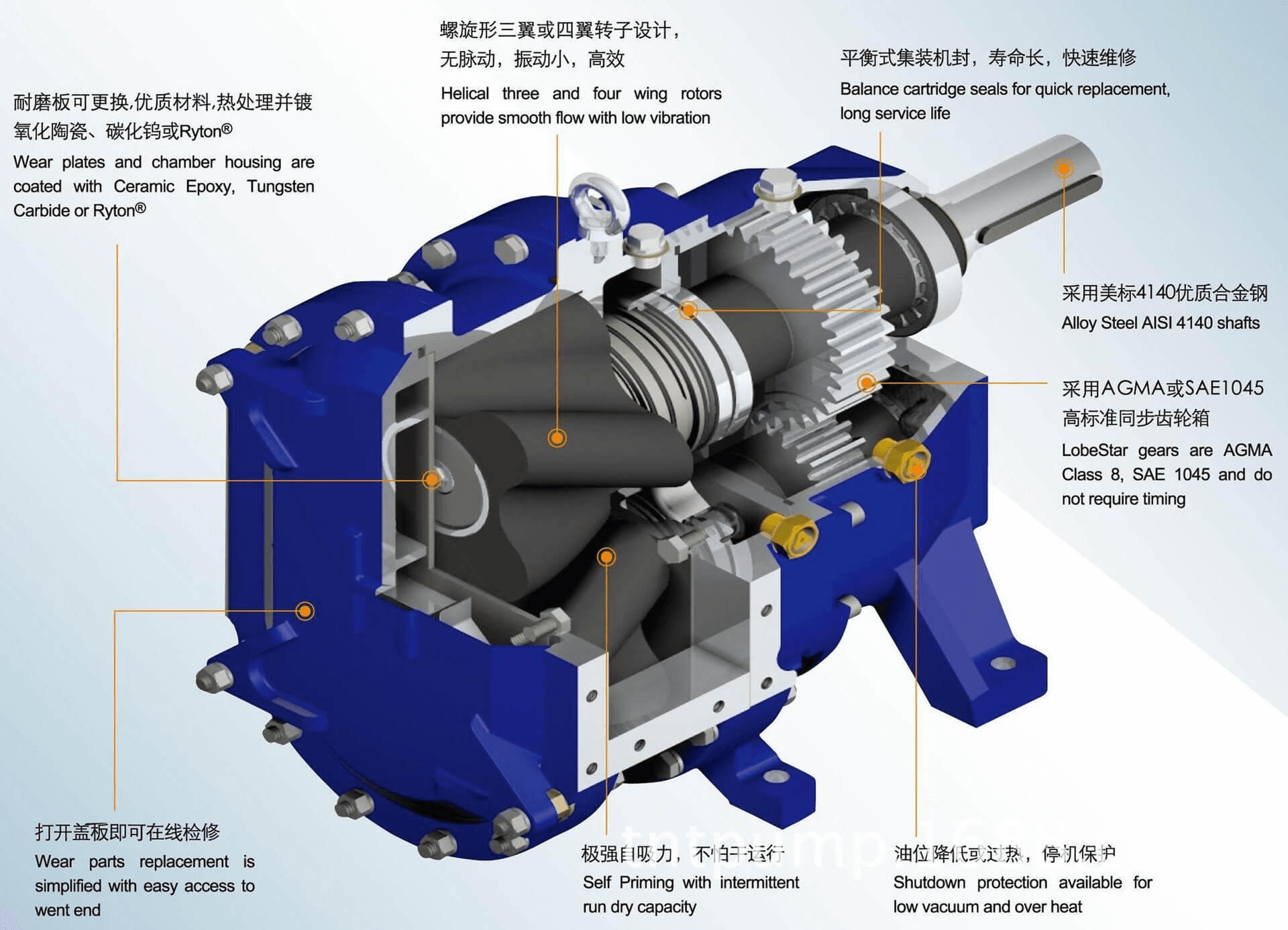

SHGB series rotor gear pump is suitable for conveying a variety of materials, and can also realize mixed conveying of gas, liquid and solid. It can also be used in environmental protection, sewage treatment, petrochemical, fire protection, food, chemical and other industries. This product has the characteristics of compact structure, small footprint, simple maintenance and strong self-priming ability.

Application:

1. Sewage Treatment: Reflux pump, excess sludge pump, in and out mud pump, lift pump, the sludge pump of the concentration tank, heavy, the sludge pump of the beginning and the second sinking.

2. Environmental Protection: Municipal sewage, chemical waste water, dewatering machine charging, scum, flotage recycling, lime slurry, seepage and sludge, etc.

3. Petrochemical Engineering: The pump cna do the mix conveying of fatlute, heavy oil, fuel oil, lubrication oil and oil-water mixture.

4. Chemical Engineering: Corrosive materials, solvents, oils, washing series and dye.

5. Catering Industry: Dairy products, jam, butter, malt juice, syrup, fruit plup.

6. Meat: Animal pluck, waste of chicken, duck and fish, minced sifh and meat.

7. Others: Coating, papermaking, resin and polymer.

8. Fire Control: Foam liquid pump, fire pump.

Feature:

1. With the features of compact structure and small cover area, saving construction cost, comparing with other types, the cover area of SHGB type is only tow thirds to one fourth of the others.

2. Convenient maintenance, to decrease the maintenance time, on-line maintenance do not need disassemble the tubes and lifting equipment, can realize the fast repair.

3. The route of the medium in the cavity is short and operation is stable, can conveying special liquids like liquid explosives.

4. It is suitable for various materials conveying, rotor and body can be chose according to the different needs.

5. To relize the mix conveying of the gas, liquid and solid like bulk material, fiber and hair without blocking.

6. With the independent sealing cavity, keeping lubrication allow the short time idle when stop the materials.

7. The pump has positive and negative rotation, can realize the assemble and disassemble functions.

8. The self-suction power is strong, the max distance can be 8.5m.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)