Summarize:

.jpg)

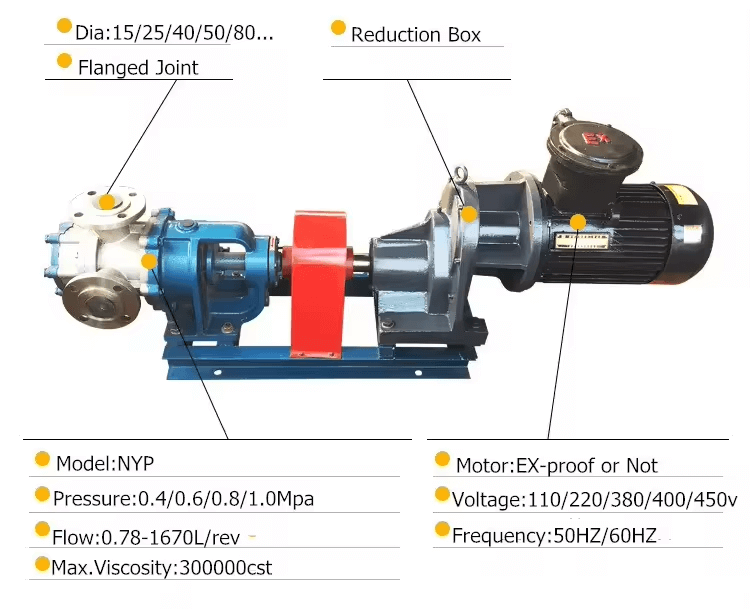

NYP series high viscosity gear pump is engineered for conveying high-viscosity, high-temperature, particulate-laden, crystallizable, and solidifiable media. It is equipped with a robust drive system, this equipment delivers substantial drive torque even at low speeds, ensuring continuous and stable material transfer while preventing product damage. Thus, this machine meets the conveying requirements of industries including pharmaceuticals, chemicals, petroleum, food, lubricants, dyes, and petroleum.

Product Details:

NYP series gear oil pump operates by retaining a certain volume of liquid within its fully enclosed housing and forcibly pushing this retained liquid into the discharge pipe. This action causes the fluid to rotate in a unidirectional manner within the pump body. During rotation, a negative pressure is generated at the suction inlet, drawing in the fluid. The rotor then conveys this fluid to the outlet, where it is expelled through the discharge port via gear meshing action.

Application:

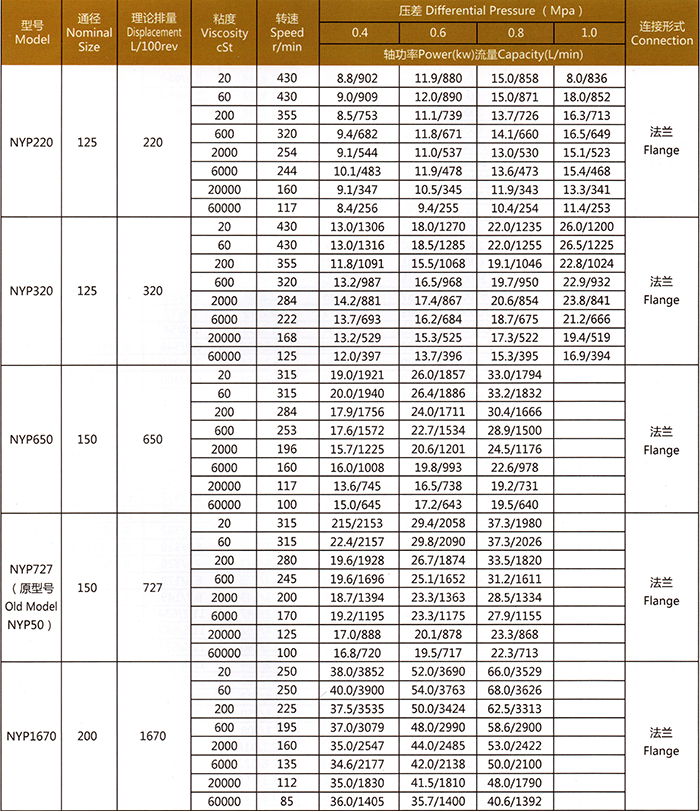

NYP series oil gear pumps are positive displacement pumps capable of conveying high-temperature liquids with viscosities ranging from 1.0 cst to 300,000 cst, as well as various corrosive liquids. They are available for transporting high-viscosity media such as asphalt, resins, adhesives, lubricants, chocolate, syrups, paints, and chemical raw materials.

Feature:

1. This pump features an insulated heating structure, with the pump body, end covers, and inlet/outlet ports all equipped with insulated jackets. It supports heating methods such as steam and thermal oil.

2. It delivers low-shear transfer, preserving the integrity of the medium structure, making it particularly suitable for conveying sensitive liquids like polymers and emulsions.

3. The internal rotor rotates in the same direction as the rotary pump, resulting in minimal wear and extended service life.

.jpg)

.png)