Summarize:

.jpg)

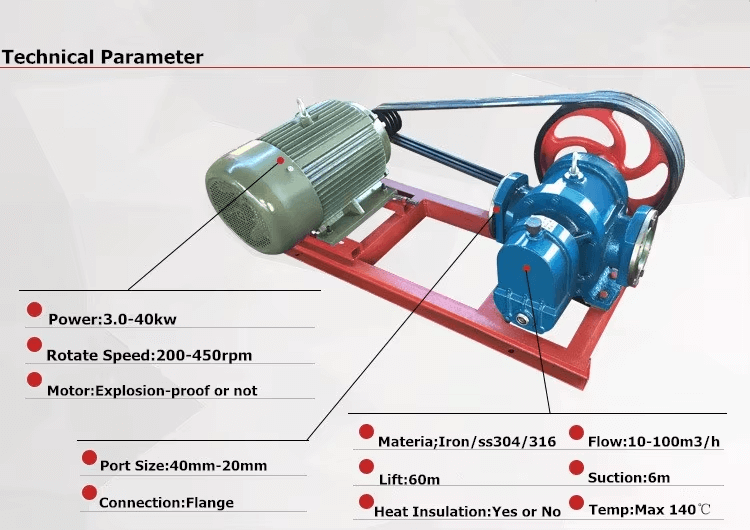

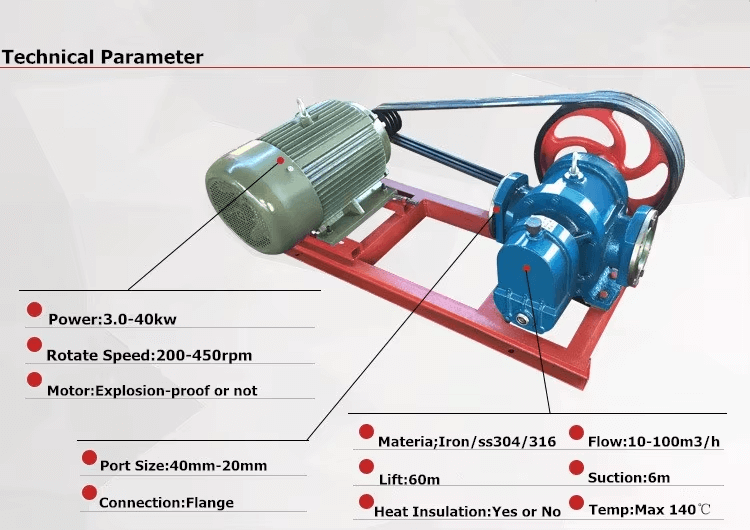

LC series roots oil pump is adapted to solve the problem of bitumen and condensation oil transportation, which is suitable for handling lubricating oil or other liquids with properties similar to lubricating oil that do not contain solid particles and fibers, are non-corrosive, and have a temperature of not more than 80℃. This machine utilizes special hot process technology to improve the surface hardness for achieving HRC60, so it is characterized by long service life and strong wear resistance.

Product Details:

LC series high viscosity roots pump consists of pump body, pump cover, shaft, gears, rotor, packing, gland and so on. This product adds heat preservation layer on the surface of pump casing or end cover, and utilizes steam or thermal oil circulation to heat up the pump, which provides convenient and good conditions for continuous and intermittent work of the pump. Moreover, in order to prevent the occurrence of air intake and oil leakage, it adopts oil-resistant sealing parts and oil return device.

Application:

LC series roots gear pump can be widely used for conveying petroleum and petroleum products (petrol can be replaced with copper pump leaves) as well as all kinds of oils and liquids in factories, such as crude oil, paints, lubricants, glass glue, fatty acids, toothpaste and so on. In food processing can also be transported such as soya milk, yeast, sugar and other liquids. Can also be used in loading and unloading of various tankers and tankers, fast, efficient, easy to use and other features, can be reversed and reverse work.

Feature:

1. This machine has compact structure, few parts, easy operation and maintenance, reliable work.

2. Its rotor relative sliding speed is very low, smooth operation, less wear and tear, low noise, long service life and so on.

3. The suction side area of this machine is large, slow change of volume between teeth, small pressure pulsation, large suction capacity.

Performance Data:

| Model |

Flow

(m³/h) |

Pressure

(Mpa) |

Inlet&Outlet Size

(mm) |

Motor |

Speed

(r/min) |

| Model |

Power

(KW) |

| LC-10/0.6 |

10 |

0.6 |

40 |

100L 2 -4 |

3.0 |

400 |

| LC-18/0.6 |

18 |

0.6 |

50 |

I 132S-4 |

5.5 |

400 |

| II 112S-4 |

4.0 |

| LC-38/0.6 |

38 |

0.6 |

65 |

132M-4 |

7.5 |

400 |

| LC-50/0.6 |

50 |

0.6 |

80 |

180M-4 |

11 |

445 |

| LC-80/0.6 |

80 |

0.6 |

200 |

225M-6 |

30 |

209 |

| LC-100/0.6 |

100 |

0.6 |

200 |

250M-6 |

37 |

254 |

| LCT-10/0.6 |

10 |

0.6 |

40 |

100L 2 -4 |

3.0 |

400 |

| LCT-18/0.6 |

18 |

0.6 |

50 |

I 132S-4 |

5.5 |

400 |

| II 112M-4 |

4.0 |

| LCT-38/0.6 |

38 |

0.6 |

65 |

132M-4 |

7.5 |

400 |

| LCT-50/0.6 |

50 |

0.6 |

80 |

180M-4 |

11 |

445 |

| LCT-80/0.6 |

80 |

0.6 |

200 |

225M-6 |

30 |

209 |

| LCT-100/0.6 |

100 |

0.6 |

200 |

250M-6 |

37 |

254 |

| LCW-10/0.6 |

10 |

10 |

40 |

100L 2 -4 |

3.0 |

400 |

| LCW-18/0.6 |

18 |

0.6 |

50 |

I 132S-4 |

5.5 |

400 |

| II 112M-4 |

4.0 |

| LCW-38/0.6 |

38 |

0.6 |

65 |

132M-4 |

7.5 |

400 |

| LCW-50/0.6 |

50 |

0.6 |

80 |

180M-4 |

11 |

445 |

| LCW-80/0.6 |

80 |

0.6 |

200 |

225M-6 |

30 |

206 |

| LCW-100/0.6 |

100 |

0.6 |

200 |

250M-6 |

37 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)