Summarize:

.jpg)

2CY series oil transfer gear pump is specifically designed for conveying lubricating oil or similar products that are non-corrosive, free of solid particles, and free of fibers, with temperatures below 300°C. It is the top choice for oil transportation, fuel oil, and hydraulic systems in ports, mining sites, factories, oil depots, marine vessels, and farms. To enhance this pump's wear resistance, the gears and shafts undergo nitriding heat treatment to achieve high hardness, enabling them to operate reliably in oil containing impurities over extended periods.

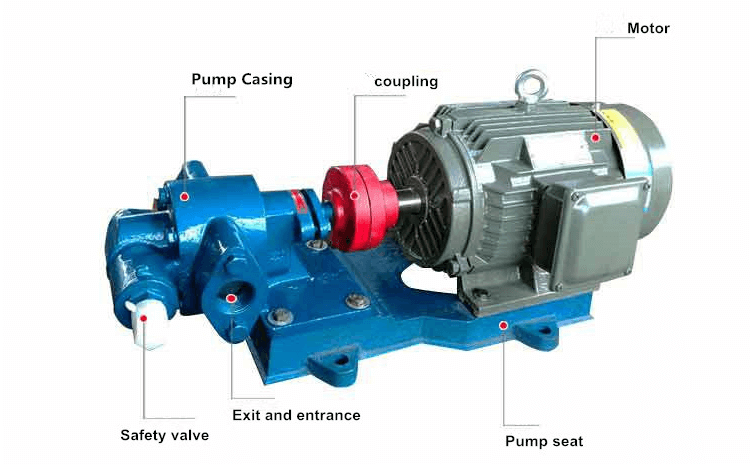

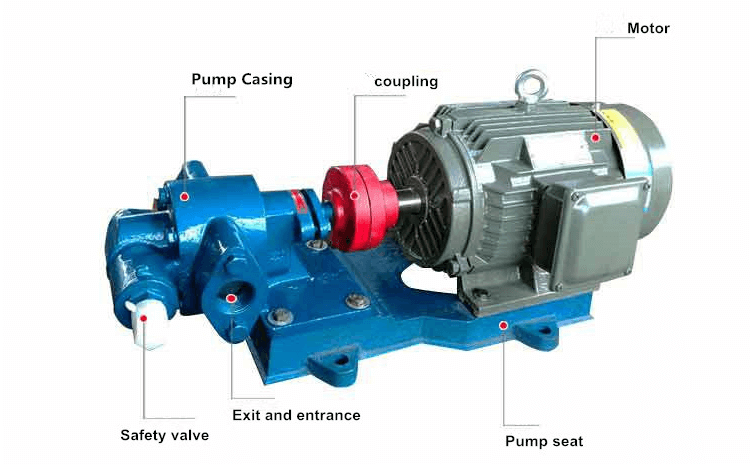

Product Details:

2CY series horizontal gear pump mainly consists of a pump body, pump cover, nitrided gears, shaft, shaft end seal, and other components. When the gears rotate, the volume of the inlet chamber changes from small to large, creating a vacuum and sucking in liquid. At the same time, as the meshing teeth continue to engage and become smaller, the oil is compressed and discharged, thereby achieving the purpose of transporting oil.

Application:

1. Hydraulic transmission system: As a power source for hydraulic systems, it is widely used in various industrial equipment and machinery requiring hydraulic power.

2. Fuel system: It can be used as a fuel pump for fuel delivery, pressurization, and injection, and is widely used in fuel supply systems for automobiles, ships, and other equipment.

3. Lubricating oil conveyance system: This equipment can serve as a conveyance and boosting pump for the conveyance of various lubricating oils and fuel oils in the petrochemical and refining industries.

4. Industrial applications: In industries such as metallurgy, mining, power generation, and building materials, it functions as a lubricating oil pump to supply lubricating oil to the lubrication systems of various mechanical equipment.

Feature:

1. The pump's key components are made of high-quality alloy steel or cast iron and undergo special heat treatment to enhance wear resistance and corrosion resistance, thereby extending service life.

2. It has a simple overall structure and reasonable design, resulting in a compact size, fewer parts, and light weight, making it easy to install and use in confined spaces.

3. This pump uses precision gear cutting, resulting in high meshing accuracy, which minimizes flow pulsation and vibration.

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)