.jpg)

.jpg)

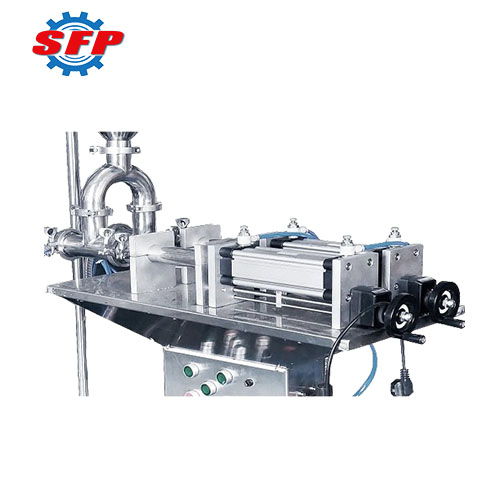

Automatic high viscosity paste filling machine is suitable for chemical, daily chemical, food, beverage, pharmaceutical and other industries to complete all kinds of viscous, non-viscous, corrosive liquid quantitative filling. The product adopts advanced metering system, which can realize accurate filling, so as to ensure the consistency of filling cool in the container. In addition, the machine is characterized by compact structure, simple operation, wide use, high filling efficiency and accurate metering.

.png)

.png)

| Model | SF-C1000 |

| Filling Method | with nozzles |

| Filling Range | 80cc-1000cc |

| Filling Speed | 20-60 BPM |

.jpg)