.jpg)

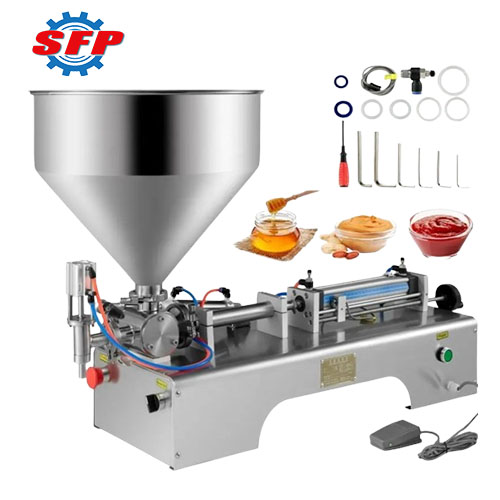

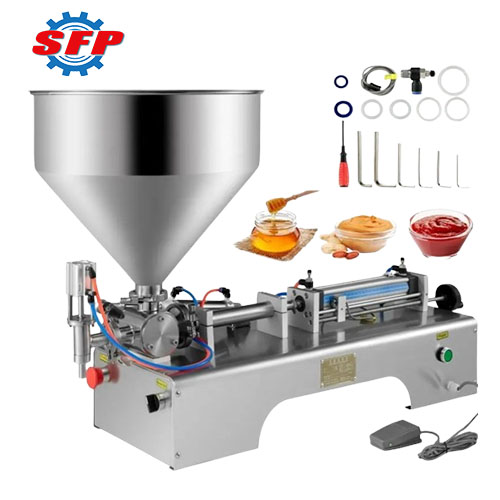

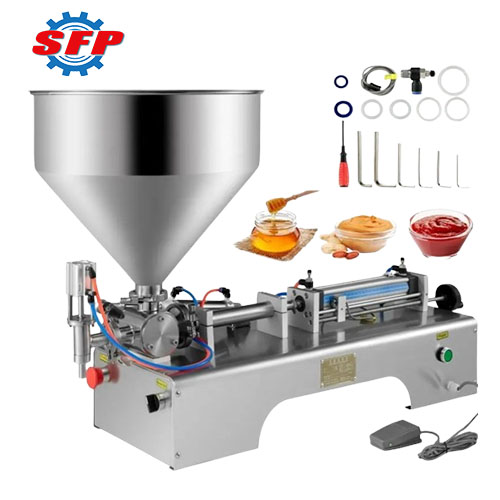

Semi automatic thick paste filling machine is designed for the filling of paste, semi-fluid, liquid, high viscosity liquid and corrosive liquid and other media. With its unique design, easy adjustment, small footprint, easy to use and other features, it has become the ideal filling equipment in pharmaceutical, chemical, food, cosmetics, pesticides and other small and medium-sized enterprises. Moreover, the parts of the product in contact with materials are made of food-grade stainless steel to ensure the hygiene of filling materials.

(3).png)

(3).png)

.png)

(2).png)

| Model | SF-C1000 |

| Filling Method | with nozzles |

| Filling Range | 80cc-1000cc |

| Filling Speed | 20-60 BPM |