.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

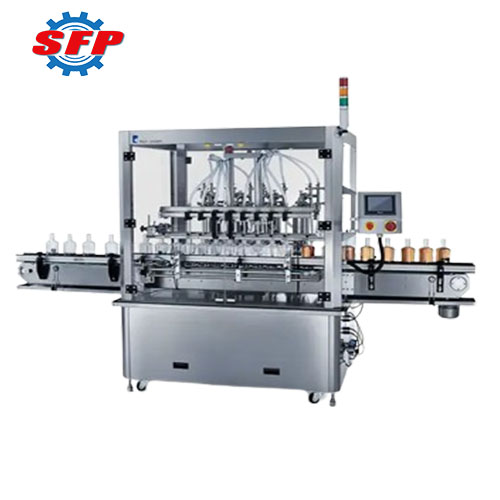

Automatic water filling machine adopts linear positioning filling, mainly used for filling mineral water, pure water, beverage, juice, edible oil, lubricating oil, cosmetics and other kinds of liquids. It can be widely used in food and beverage, pharmaceutical, daily chemical, chemical and other industries. At the same time, the equipment is made of high-quality stainless steel material, in line with food hygiene standards, so it can be used in the filling process to avoid liquid contamination and cross-contamination, so as to ensure the safety and hygiene of the liquid to be filled.

.png)

1. The equipment is specially designed for high-speed production and can greatly increase the total production capacity of beverage production. Its fast and efficient operation process can not only meet different production needs, but also increase production without affecting product quality.

2. Automation reduces dependence on manual operation, thereby reducing labor costs and bringing potential cost savings to the enterprise.

| Model | RCGF14-12-5 | RCGF16-16-5 | RCGF24-24-8 | RCGF32-32-8 | RCGF40-40-12 | RGF60-60-15 |

| Capacity(for 500ml) | 2000BPH | 4000BPH | 8000-10000BPH | 12000-15000BPH | 16000-18000BPH | 24000BPH |

| Suitable Bottle Shapes | circular or square | |||||

| Bottle Diameter(mm) | Dia50-Dia115mm | |||||

| Bottle Height (mm) | 160-320mm | |||||

| Filling Type | Overflow filling type | |||||

| Function | Rinsing filling capping | |||||

| Rinsing Pressure(Mpa) | >0.06Mpa <0.2Mpa | |||||

| Application | Juice / Tea Drinks / Milk Beverage | |||||

| Total Power (KW) | 4.4kw | 4.4kw | 4.4kw | 5.2kw | 6.2kw | 7.8kw |

| Overall Dimensions(m) | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height(m) | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

| Weight(kg) | 3500kg | 5200kg | 7000kg | 9500kg | 10500kg | 12000kg |