.jpg)

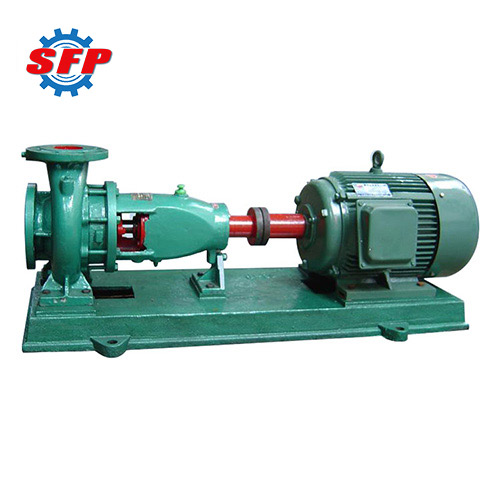

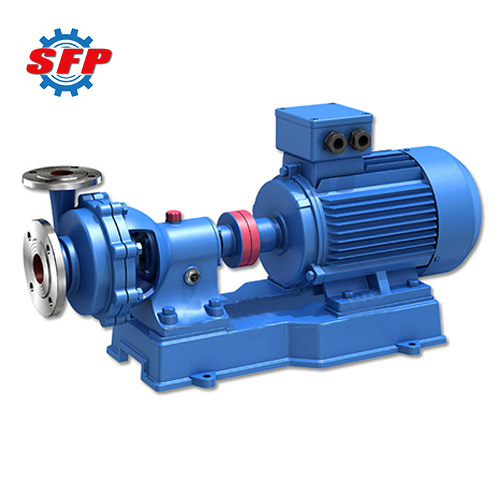

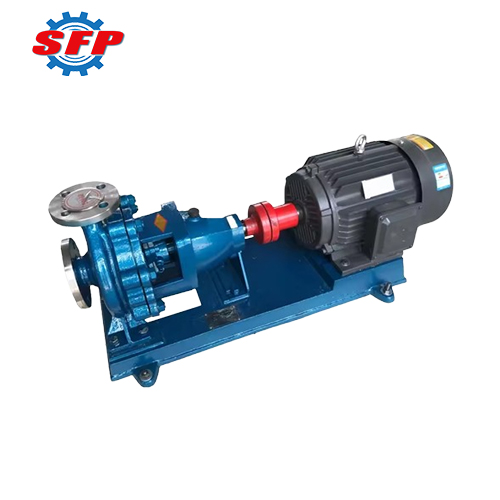

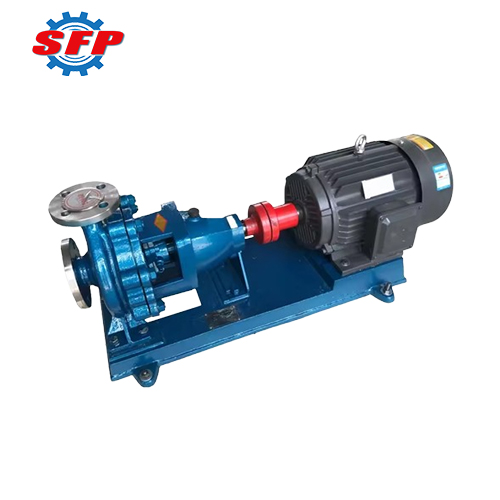

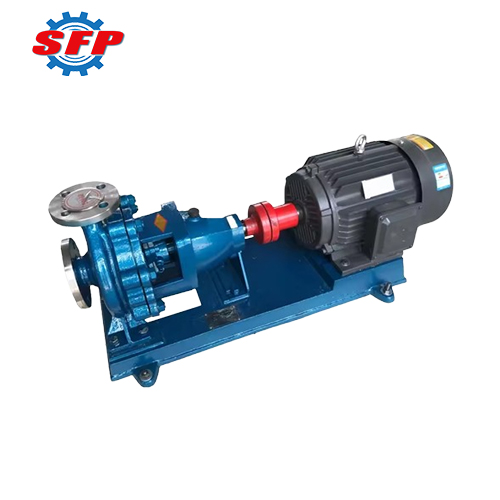

IH series chemical centrifugal pump adopts the international standard ISO2858 for its rated performance, shape and size, and is an energy-saving replacement for F-type corrosive centrifugal pump of the ministry of machinery industry. This pump can transport corrosive liquids without solid particles and with viscosity similar to that of water, and can be applied in petroleum, chemical, electric power, pharmacy, food, smelting, mining, oil unloading from tankers, chemical fiber synthesis and other fields.Meanwhile, this equipment is characterized by high efficiency and energy saving, high reliability, long service life, reliable sealing performance, corrosion resistance and high mechanical strength.

IH series horizontal chemical pumps are mainly composed of vane drive system, sealing nut, pump cover, impeller, intermediate bracket, seals, suspension parts, shaft and other components. The pump cover comes up to connect the middle through the middle fixed bracket, and then connects with the bracket through the pump body. The pump body is designed as axial suction, radial discharge, foot bearing type, which can be fixed on the base directly. Meanwhile, the suspension parts are supported on the base together with the suspension bracket through the connector on the intermediate fixing bracket. The pump is equipped with an extension coupling, in other words, the inlet and outlet connection lines, the pump body and the motor can be maintained without disassembly.

.png)

.png)

IH series centrifugal chemical pumps are used for conveying liquids without solid particles, corrosive and with viscosity similar to water. It can be used in petroleum, chemical industry, metallurgy, electric power, papermaking, food, pharmacy and synthetic fiber and other departments.

.png)

| Model | Speed | Flow (m³/h) |

Flow (L/S) |

Head (m) |

Power | ||

| Medium Density | |||||||

| 1.0 | 1.35 | 1.85 | |||||

| IH50-32-125 | 2900 | 12.5 | 3.47 | 20 | 2.2 | 6.0 | 4.0 |

| 1450 | 6.3 | 1.74 | 5.0 | 0.55 | 0.55 | 0.55 | |

| IH50-32-160 | 2900 | 12.5 | 3.47 | 32 | 3.0 | 4.0 | 5.5 |

| 1450 | 6.3 | 1.74 | 8.0 | 0.55 | 0.75 | 1.1 | |

| IH50-32-200 | 2900 | 12.5 | 3.47 | 50 | 5.5 | 7.5 | 11 |

| 1450 | 6.3 | 1.74 | 12.5 | 1.1 | 1.1 | 1.5 | |

| IH50-32-250 | 2900 | 12.5 | 3.47 | 80 | 11 | 15 | 18.5 |

| 1450 | 6.3 | 1.74 | 20 | 2.2 | 2.2 | 3.0 | |

| IH65-50-125 | 2900 | 25 | 1.53 | 2.0 | 3.0 | 4.0 | 5.5 |

| 1450 | 12.5 | 6.94 | 5.0 | 0.55 | 0.55 | 0.75 | |

| IH65-50-160 | 2900 | 25 | 2.78 | 32 | 5.5 | 7.5 | 11 |

| 1450 | 12.5 | 6.94 | 8.0 | 0.75 | 1.1 | 1.5 | |

| IH65-40-200 | 2900 | 25 | 2.92 | 50 | 11 | 11 | 15 |

| 1450 | 12.5 | 6.94 | 12.5 | 1.5 | 2.2 | 2.2 | |

| IH65-40-250 | 2900 | 25 | 2.92 | 80 | 15 | 3.0 | 30 |

| 1450 | 12.5 | 6.94 | 20 | 2.2 | 37 | 4.0 | |

| IH65-40-315 | 2900 | 25 | 3.06 | 125 | 30 | 5.5 | 55 |

| 1450 | 12.5 | 6.94 | 32.0 | 5.5 | 5.5 | 7.5 | |

| IH80-65-125 | 2900 | 50 | 13.9 | 20 | 5.5 | 7.5 | 11 |

| 1450 | 25 | 6.94 | 5.0 | 0.75 | 1.1 | 1.5 | |

| IH80-65-160 | 2900 | 50 | 13.9 | 32 | 11 | 11 | 15 |

| 1450 | 25 | 6.94 | 8.0 | 1.5 | 1.5 | 2.2 | |

| IH80-50-200 | 2900 | 50 | 13.9 | 50 | 15 | 18.5 | 30 |

| 1450 | 25 | 6.94 | 12.5 | 1.1 | 1.5 | 2.2 | |

| IH80-50-250 | 2900 | 50 | 13.9 | 80 | 30 | 37 | 45 |

| 1450 | 25 | 6.94 | 20 | 4.0 | 5.5 | 7.5 | |

| IH80-50-315 | 2900 | 50 | 13.9 | 125 | 45 | 55 | 75 |

| 1450 | 25 | 6.94 | 32 | 7.5 | 7.5 | 11 | |

| IH100-80-125 | 2900 | 100 | 27.8 | 20 | 11 | 15 | 18.5 |

| 1450 | 50 | 13.9 | 5.0 | 1.5 | 2.2 | 3.0 | |

| IH100-80-160 | 2900 | 100 | 27.8 | 32 | 15 | 22 | 30 |

| 1450 | 50 | 13.9 | 8.0 | 2.2 | 3.0 | 4.0 | |

| IH100-65-200 | 2900 | 100 | 27.8 | 50 | 30 | 37 | 45 |

| 1450 | 50 | 13.9 | 12.5 | 3.0 | 4.0 | 5.5 | |

| IH100-65-250 | 2900 | 100 | 27.8 | 80 | 45 | 55 | 75 |

| 1450 | 50 | 13.9 | 20 | 5.5 | 7.5 | 11 | |

| IH100-65-315 | 2900 | 100 | 55.6 | 125 | 75 | 90 | 132 |

| 1450 | 50 | 27.8 | 32 | 11 | 15 | 18.5 | |

| IH125-100-200 | 2900 | 200 | 55.6 | 50 | 45 | 55 | 90 |

| 1450 | 100 | 27.8 | 12.5 | 7.5 | 11 | 15 | |

| IH125-100-250 | 2900 | 200 | 55.6 | 80 | 11 | 110 | 132 |

| 1450 | 100 | 27.8 | 20 | 132 | 15 | 18.5 | |

| IH125-100-315 | 2900 | 200 | 55.6 | 125 | 18.5 | 160 | 220 |

| 1450 | 100 | 27.8 | 32 | 18.5 | 22 | 30 | |

| IH125-100-400 | 1450 | 100 | 27.8 | 50 | 18.5 | 30 | 37 |

| IH50-125-250 | 1450 | 200 | 55.6 | 20 | 30 | 30 | 37 |

| IH50-125-315 | 1450 | 200 | 55.6 | 32 | 30 | 37 | 55 |

| IH50-125-400 | 1450 | 200 | 55.6 | 50 | 55 | 75 | 90 |

| IH200-150-250 | 1450 | 400 | 111.1 | 20 | 37 | 55 | 75 |

| IH200-150-315 | 1450 | 400 | 111 | 32 | 55 | 75 | 110 |

| IH200-150-400 | 1450 | 400 | 111 | 50 | 90 | 132 | 160 |