.png)

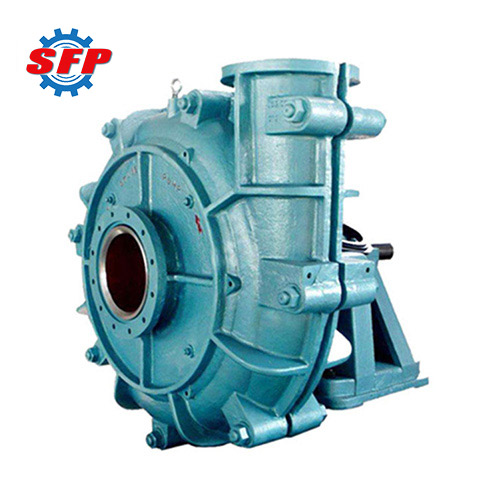

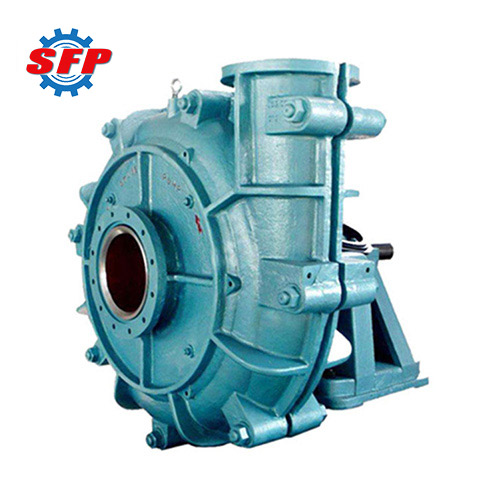

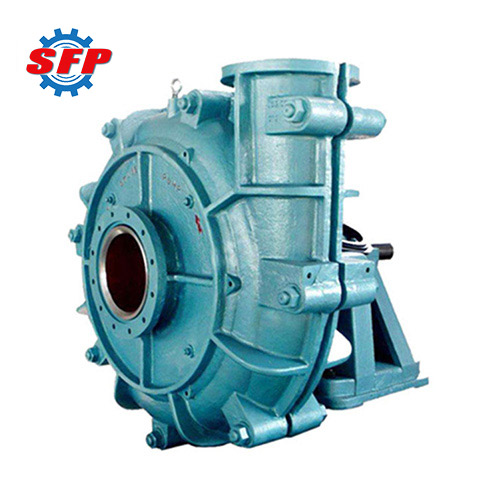

AH series slurry centrifugal pumps can transport strongly abrasive slurry in small flow and low head area, and lightly abrasive slurry in high head and high flow area, and can also be used in multi-stage series to meet the long-distance transport. They are usually widely used in mill discharge, power generation sector and tailings as well as in specialised areas. The machine offers excellent wear life whilst maintaining efficiency over the wear cycle, thus providing optimum total cost of operation.

| Model | Capacity | Head | Speed | NPSHr | Efficiency | Shaft Power | Power | Dia. of Pump | |

| (m3/h) | (m) | ( r/min) | (m) | (%) | (kw) | (kw) | Inlet | Outlet | |

| 1.5/1B-AH(R) | 3.6-22 | 5-70 | 1200-3800 | 3.2 | 20-40 | 0.34-9.36 | 1.5-15 | 38 | 25 |

| 2/1.5B-AH(R) | 7.2-50 | 7-61 | 1200-3200 | 3 | 18-45 | 0.93-13.5 | 1.5-15 | 51 | 38 |

| 3/2C-AH(R) | 21.6-89 | 13-63 | 1300-2700 | 3 | 45-60 | 1.9-24.1 | 4-30 | 76 | 51 |

| 4/3C-AH(R) | 28.8-155 | 7-44 | 1000-2000 | 2.2-6 | 50-74 | 1.73-22.54 | 5.5-30 | 102 | 76 |

| 4/3D-AH(R) | 28.8-155 | 7-44 | 1000-2000 | 2.2-6 | 50-74 | 1.73-22.54 | 5.5-37 | 102 | 76 |

| 6/4D-AH(R) | 72-360 | 12.6-54 | 800-1480 | 3-6.8 | 50-68 | 6.27-51.07 | 15-55 | 152 | 102 |

| 6/4E-AH(R) | 93.6-385 | 21.7-58 | 1050-1600 | 3-7.8 | 50-68 | 11.9-101 | 22-110 | 152 | 102 |

| 8/6E-AH(R) | 126-648 | 10-58 | 500-1100 | 2-7.5 | 51-72 | 8.1-103 | 22-110 | 203 | 152 |

| 10/8ST-AH | 216-972 | 11-46 | 400-730 | 2-8.5 | 50-71 | 16.47-158 | 45-250 | 254 | 203 |

| 12/10ST-AH | 316.8-1620 | 10-55 | 350-730 | 2-7.2 | 60-80 | 18.26-249 | 30-380 | 305 | 254 |

| 14/12ST-AH | 504-2455 | 13-61 | 300-590 | 2-12.8 | 60-77 | 36.6-449 | 55-480 | 356 | 305 |