.png)

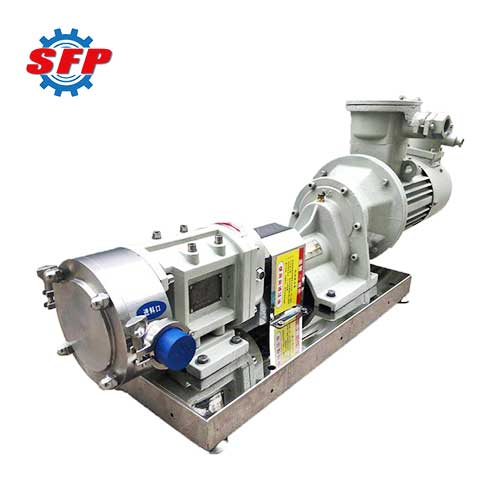

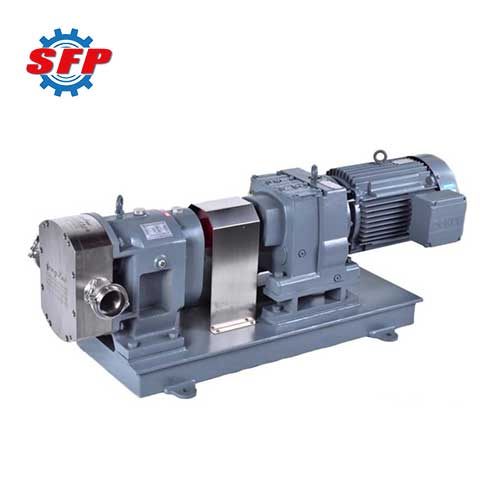

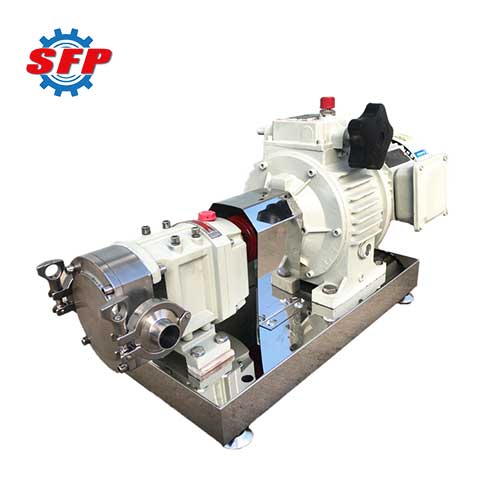

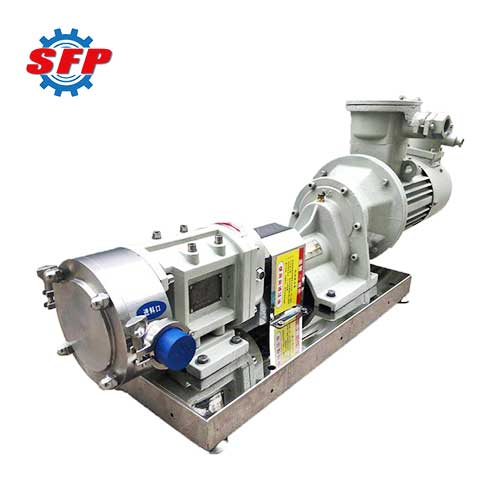

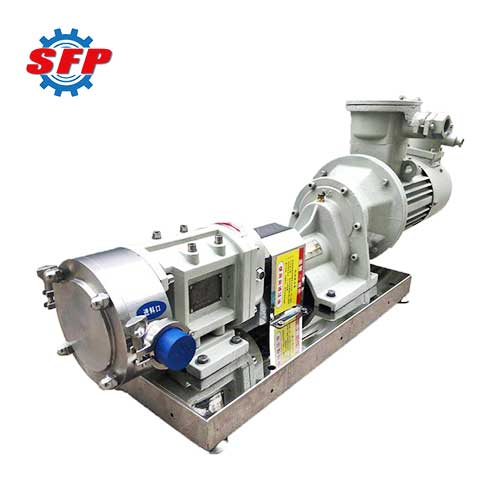

3RP rotary lobe pump is a rotary positive displacement pump with high efficiency and long life. It is suitable for conveying temperature -30℃~200℃, viscosity 30~100000mm2/s, suspended liquid containing solid particles and media with high requirements for corrosiveness and hygiene. The parts inside the pump body that are in contact with the medium are all made of stainless steel, and the speed of the pump can be changed according to the different physical characteristics of the medium.

The pump is made of two synchronous rotors/lobes. Rotors are driven by a pair of synchronous gears in the gearbox. Two rotors are rotated in the opposite direction driven by the main and auxiliary shafts, which causes the volume of the pump to change, thus forming a higher vacuum and discharge pressure . This kind of pump is especially suitable for delivering hygienic fluid and corrosive high viscosity fluid. The core components and sealing devices of the pump are designed according to different characteristics of different fluid, using different materials and sealing types, which improves the professional conveying performance of the product.

| Model | Flow | Discharge Pressure (Mpa) |

Rev (rpm) |

Motor Power (kw) |

Inlet/outlet (mm) |

|

| L/100r | m3/h | |||||

| 3RP-25 | 6 | ≤1.8 | 0-1.0 | 10-400 | 0.75 | 25 |

| 3RP-32 | 9 | ≤2.7 | 1.1 | 32 | ||

| 3RP-40 | 18 | ≤4.3 | 1.5 | 40 | ||

| 3RP-50 | 36 | ≤8.6 | 2.2 | 50 | ||

| 3RP-65 | 60 | ≤14.4 | 4 | 65 | ||

| 3RP-80 | 105 | ≤25.2 | 11 | 80 | ||

| 3RP-100A | 125 | ≤30 | 15 | 100 | ||

| 3RP-100 | 150 | ≤36 | 18.5 | 100 | ||

| 3RP-125 | 250 | ≤60 | 22 | 125 | ||