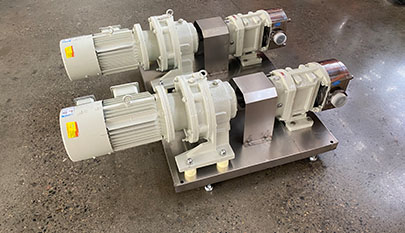

Application of lobe rotor pump in food and chemical industry

Lobe rotor pumps have found extensive applications in various industries, including the food and chemical industry. These pumps are known for their ability to handle viscous liquids, delicate materials, and solids, making them ideal for a wide range of processes.

LEARN MORE

DATE:Jul 17th, 2023