In the production and processing of honey, maintaining sanitary conditions and preserving the quality of the product are paramount. One key component in this process is the lobe pump, specifically designed for handling high viscosity substances like honey. This article explores the features, benefits, and applications of the stainless steel lobe pump in ensuring the efficient and hygienic transfer of high viscosity honey.

Features and Design:

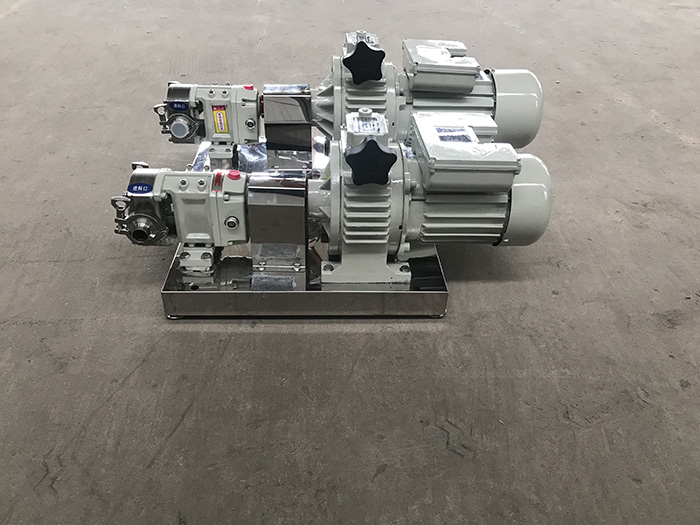

The lobe pump is an essential tool for the food industry, particularly in honey processing. The pump's design consists of two rotating lobes within a close-fitting chamber. The lobes create a positive displacement action, allowing for the smooth transfer of high viscosity liquids like honey. The sanitary rotor design ensures minimal product degradation and preserves the integrity of the honey during transportation.

The lobe pump's main components are constructed from stainless steel, a material known for its excellent corrosion resistance and hygienic properties. Stainless steel surfaces are smooth, preventing the accumulation of contaminants and providing ease of cleaning. This design ensures that the honey remains uncontaminated and maintains its quality throughout the transfer process.

Benefits:

1. Sanitary Transfer: The lobe pump's stainless steel construction and sanitary rotor design make it an ideal choice for transferring high viscosity honey while maintaining the highest sanitary standards. The pump's smooth surfaces and absence of dead spaces eliminate the risk of bacterial growth or cross-contamination.

2. Gentle Handling: The positive displacement action of the lobe pump ensures gentle handling of honey, minimizing shear forces and preventing degradation or alteration of the product. This feature is particularly crucial for preserving the natural flavor, aroma, and nutritional properties of honey.

3. High Efficiency: The lobe pump's efficient design allows for a consistent flow rate, regardless of the viscosity of the honey. This ensures optimal production efficiency, minimizes product waste, and reduces production downtime.

4. Versatility: The lobe pump is not limited to handling honey; it is also suitable for transferring other high viscosity substances, such as syrups, molasses, and thick pastes. This versatility makes it an indispensable tool in various food processing applications.

Applications:

The stainless steel lobe pump finds wide applications in the honey industry and other food processing sectors. Some notable applications include:

1. Honey Production: From transferring honey from storage tanks to packaging lines, the lobe pump ensures a smooth and efficient process without compromising the quality of the final product.

2. Honey Blending: The lobe pump is used for blending different types of honey, maintaining consistency in taste, color, and texture throughout the mixing process.

3. Syrup and Molasses Handling: The lobe pump efficiently transfers syrups and molasses, ensuring precise flow control and preventing crystallization or separation.

4. Food Manufacturing: The lobe pump is valuable in various food production processes that involve high viscosity substances, such as processing jams, jellies, and sauces.

The stainless steel lobe pump is an indispensable tool in the honey industry, ensuring the efficient and sanitary transfer of high viscosity honey. Its sanitary rotor design, gentle handling, high efficiency, and versatility make it an essential component in honey processing and other food manufacturing applications. By maintaining the highest sanitary standards, preserving the quality of the honey, and offering reliable performance, the lobe pump plays a crucial role in the production of high-quality honey products.