Summarize:

.jpg)

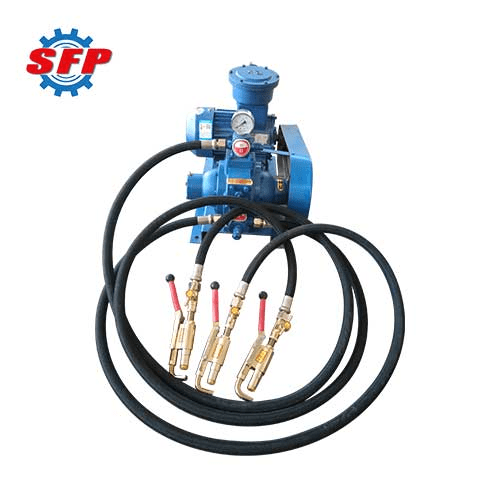

LPG gas filling pumps are high-performance fluid transfer equipment developed by our company for low-viscosity, vaporizable, flammable, and explosive media such as liquefied petroleum gas, dimethyl ether, liquid ammonia, propane, and butane. Combining the advantages of multistage centrifugal pumps and vane pumps, this product meets the comprehensive requirements of LPG loading/unloading facilities, cylinder filling stations, liquefied gas storage tank farms, and marine loading/unloading operations.

Product Details:

LPG gas transfer filling pump employs an advanced volumetric vane pump design. The stator surface features a composite curve configuration, with mechanical seals installed at both ends. As the rotor rotates, the inlet chamber volume gradually increases, creating a vacuum that generates suction to draw in the liquid. When the rotor rotates to a specific angle, the chamber volume progressively decreases, thereby achieving oil discharge.

Application:

LPG gas transfer pumps are primarily used for conveying various volatile liquids and petroleum products with similar properties, including liquefied petroleum gas, dimethyl ether, methyl chloride, ethylene oxide, propane, propylene, butadiene, isobutylene, and methanol. They are particularly suitable for operations such as loading/unloading liquefied petroleum gas tank trucks, filling gas cylinders, and supplying gas to workshops.

Feature:

1. Internal rotating components feature coordinated metal-nonmetal design to prevent static electricity generation.

2. With zero-leakage safety design and optional explosion-proof motors, it can be safely deployed in flammable and explosive environments.

3. Its pump body incorporates comprehensive safety protections including overload protection and leakage protection, ensuring operational safety and reliability.

Performance Data:

| Model |

Speed

(r.p.m) |

Flow

(m³/h) |

Pressure Difference

(MPa) |

Working Pressure

(MPa) |

Power

(kW) |

Inlet Size

(inch) |

Outlet Size

(inch) |

Temperature Range

(℃) |

| YQB2-5 |

600 |

2 |

0.5 |

1.6 |

1.5 |

1 |

1 |

+40

-40 |

| YQB5-5 |

780 |

5 |

2.2 |

1.2 |

1.2 |

| YQB10-5 |

600 |

10 |

0.5 |

1.6 |

5.5 |

2 |

2 |

+40

-40 |

| YQB15-5 |

780 |

15 |

| YQB15-5A |

780 |

15 |

0.4 |

1.6 |

4 |

2 |

2 |

+40

-40 |

| YQB10-5A |

600 |

10 |

| YQB25-5 |

600 |

25 |

0.5 |

1.6 |

11 |

3 |

3 |

+40

-40 |

| YQB35-5 |

780 |

35 |

| YQB50-5 |

600 |

50 |

0.5 |

1.6 |

15 |

4 |

4 |

+40

-40 |

| YQB60-5 |

780 |

60 |

0.5 |

1.6 |

15 |

4 |

4 |

+40

-40 |

| YQB80-5 |

780 |

80 |

0.5 |

1.6 |

18.5 |

4 |

4 |

+40

-40 |

.png)

.jpg)