Summarize:

.jpg)

CDLF series multistage centrifugal pump is a highly efficient, energy-saving, and environmentally friendly vertical multi-stage centrifugal pump suitable for conveying various media ranging from tap water to mildly corrosive industrial liquids. This series of pumps employs advanced hydraulic models and manufacturing processes, with a design that prioritizes energy efficiency, environmental protection, safety, and reliability. As a result, the pump achieves significant energy savings and can be equipped with an intelligent protector to provide effective protection against dry running, phase loss, and overload conditions.

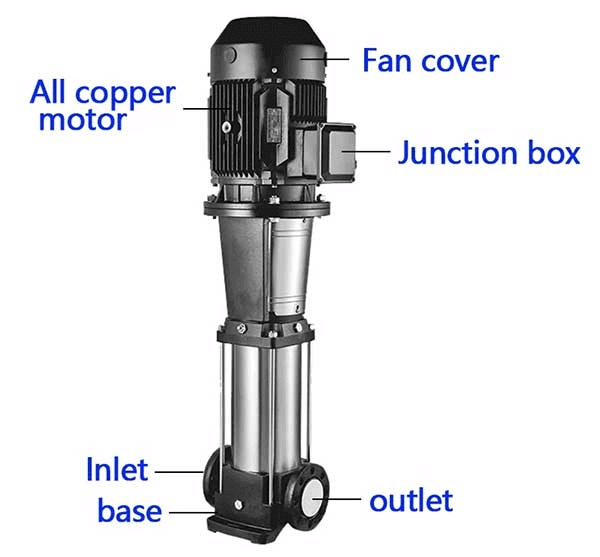

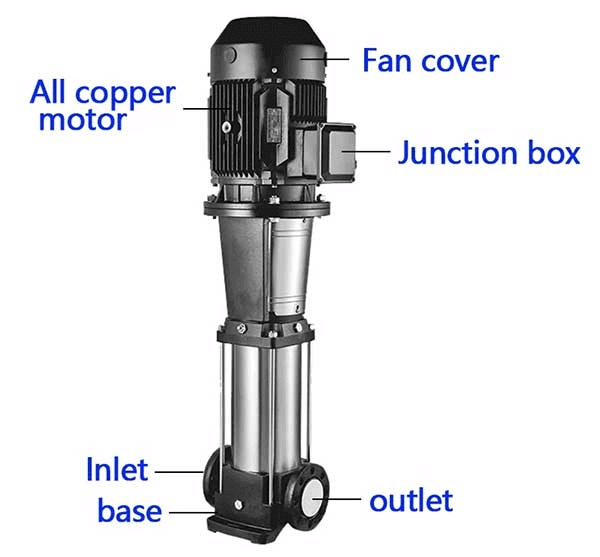

Product Details:

CDL series vertical multistage centrifugal pump adopts new sealing technology and is equipped with a stainless steel mechanical seal that is easy to disassemble. The pump is driven by a standard motor, and the motor output shaft is directly connected to the pump shaft through a coupling. Its pressure-resistant cylinder body and impeller assembly can be fixed between the pump head and the inlet and outlet sections with solid bolts, and their position must be on the same plane as the bottom of the pump.

Application:

1. Irrigation Systems: Agricultural irrigation, sprinkler irrigation, drip irrigation.

2. Industrial Boosting: Process water systems, cleaning systems, high-pressure washing systems, fire protection systems.

3. Water Treatment: Ultrafiltration systems, reverse osmosis systems, distillation systems, swimming pool water treatment.

4. Water Supply Systems: Water treatment plant filtration and distribution, zoned water supply, and pressure boosting for high-rise buildings.

5. Industrial Liquid Conveyance: Cooling and air conditioning systems, boiler feedwater and condensation systems, machine tool auxiliary systems, acid-base medium conveyance.

Feature:

1. Both the inlet and outlet ports of the pump are located on the same horizontal plane as the pump base, enabling direct integration into pipeline systems.

2. Utilizing an advanced hydraulic model and state-of-the-art manufacturing techniques, the pump’s performance and service life have been significantly enhanced.

3. The machine's shaft seal uses mechanical seals made of hard alloy and fluororubber, enhancing the pump's operational reliability and the temperature of the conveyed medium.

4. The intelligent protection device can be configured according to user requirements, effectively preventing damage to the pump caused by dry running, phase loss, and overload.

5. The overflow section of the machine is constructed using stainless steel plates through stamping and welding processes, making the pump suitable for use with mildly corrosive media.

Performance Data:

| Model |

Power |

Flow Rate |

1 |

1.2 |

1.6 |

2 |

2.4 |

2.8 |

3.2 |

3.5 |

| (KW) |

(m³/h) |

| CDL2.2 |

0.37 |

H(m) |

18 |

17 |

16 |

15 |

13 |

12 |

10 |

8 |

| CDL2.3 |

0.37 |

H(m) |

27 |

26 |

24 |

22 |

20 |

18 |

15 |

12 |

| CDL2.4 |

0.55 |

H(m) |

36 |

35 |

33 |

30 |

26 |

24 |

20 |

16 |

| CDL2.5 |

0.55 |

H(m) |

45 |

43 |

40 |

37 |

33 |

30 |

24 |

20 |

| CDL2.6 |

0.75 |

H(m) |

53 |

52 |

50 |

45 |

40 |

36 |

30 |

24 |

| CDL2.7 |

0.75 |

H(m) |

63 |

61 |

57 |

52 |

47 |

41 |

35 |

28 |

| CDL2.9 |

1.1 |

H(m) |

80 |

78 |

73 |

67 |

61 |

54 |

45 |

37 |

| CDL2.11 |

1.1 |

H(m) |

98 |

95 |

89 |

82 |

73 |

64 |

54 |

44 |

| CDL2.13 |

1.5 |

H(m) |

116 |

114 |

106 |

98 |

89 |

78 |

65 |

52 |

| CDL2.15 |

1.5 |

H(m) |

134 |

130 |

123 |

112 |

100 |

90 |

73 |

60 |

| CDL2.18 |

2.2 |

H(m) |

161 |

157 |

148 |

136 |

121 |

108 |

91 |

76 |

| CDL2.22 |

2.2 |

H(m) |

197 |

192 |

180 |

165 |

148 |

130 |

110 |

90 |

| CDL2.26 |

2.2 |

H(m) |

232 |

228 |

214 |

198 |

179 |

158 |

130 |

110 |

.png)

.jpg)