Summarize:

.jpg)

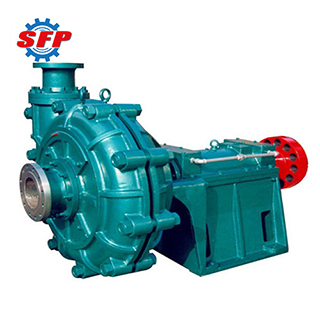

YZ series submerged mining vertical slurry pump draws on the advanced production experience in the field of liquid slurry pump, is the latest generation of new liquid slurry pump. The pump is a vertical single-stage single-suction cantilevered centrifugal pump, usually used for environmental protection, refineries, steel mills, mines, metallurgy, chemical industry, pharmaceuticals and other industries pumping heavy oil, oil slag, slurry, sand and gravel and some corrosive liquids.

Product Details:

YZ series single stage vertical slurry pump is vertical single-stage single-suction cantilevered centrifugal pump structure, the impeller is a half-open impeller, and the extension of the suction side of the impeller is equipped with stirring vanes. It draws on the advanced production experience in the field of submerged slurry pump, and introduces the latest generation of new submerged slurry pump. The impeller is half-open impeller, the extension part of the suction side of the impeller is equipped with stirring vane.

Application:

YZ series single stage vertical slurry pump is mainly used in environmental protection, municipal engineering, thermal power plants, gas coking plants, oil refineries, steel plants, mining, paper industry, cement plants, food plants, printing and dyeing and other industries to pump concentrate, heavy oil, oil residue, dirty liquid , mud, mortar, quicksand and flowing sludge in urban sewage channels, as well as liquids containing coal lumps and ash. It can also be used for pumping fluids and corrosive liquids containing mud, sand and slag in chemical, pharmaceutical and other industries.

Feature:

1. The pump shaft of this submerged section is sufficiently rigid. There is no bearing between the impeller and the pump casing, and no shaft seal is used, so that relatively large concentrations of solids can be conveyed.

2. It adopts single-stage single-suction cantilever structure. The hydraulic elements of the pump are connected to the bearing seat, support seat and connecting pipe.

3. The drive unit is mounted on the motor bracket and bracket seat by means of a vertical motor and connected to the pump by means of a coupling.

4. The impeller of the pump is a semi-open impeller with stirring vanes at the extension of the impeller vane inlet.

5. It shaft seal is operated by means of a submerged pump inserted into the liquid and no shaft seal is used.

.jpg)

.jpg)

.png)